Sealed fireproof door

A fire door and sealing technology, which is applied in the field of building materials, can solve the problems of inconvenient installation for workers and users, manual locking of fire doors, and inconvenience in the escape process, so as to avoid casualties and property losses, protect safe escape, and facilitate The effect of personnel escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

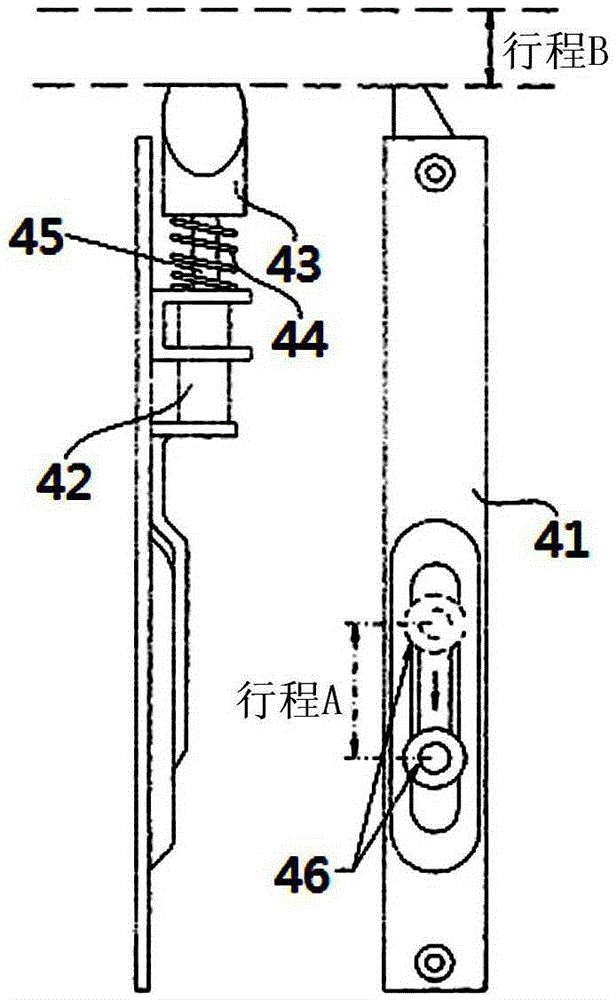

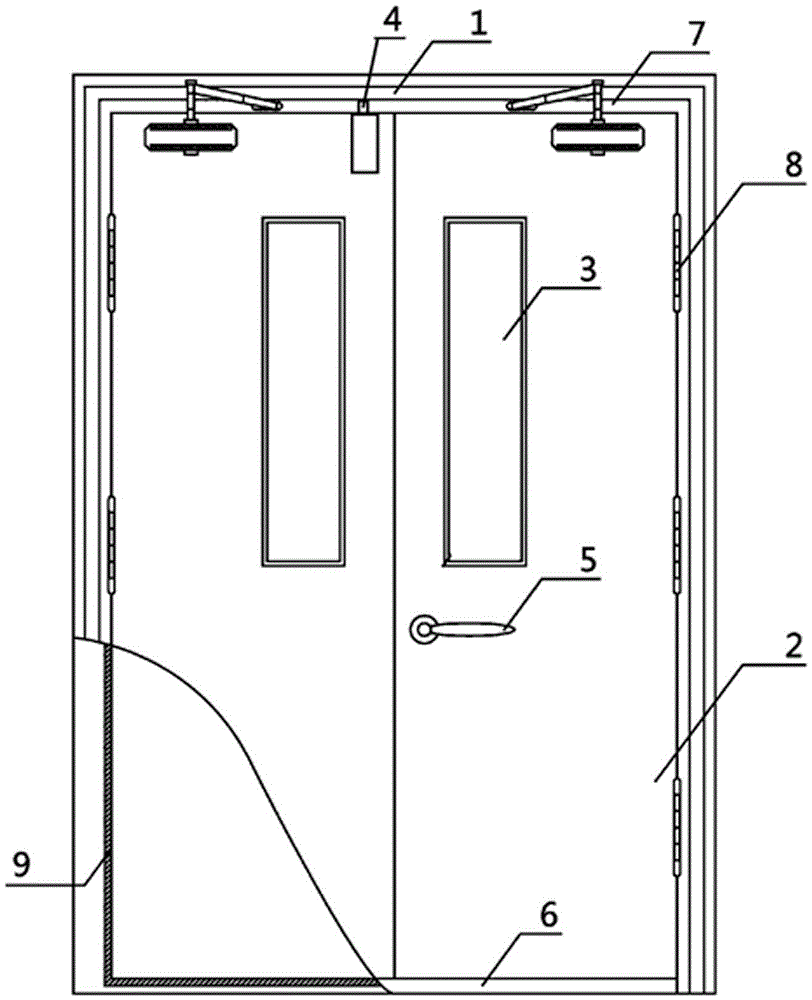

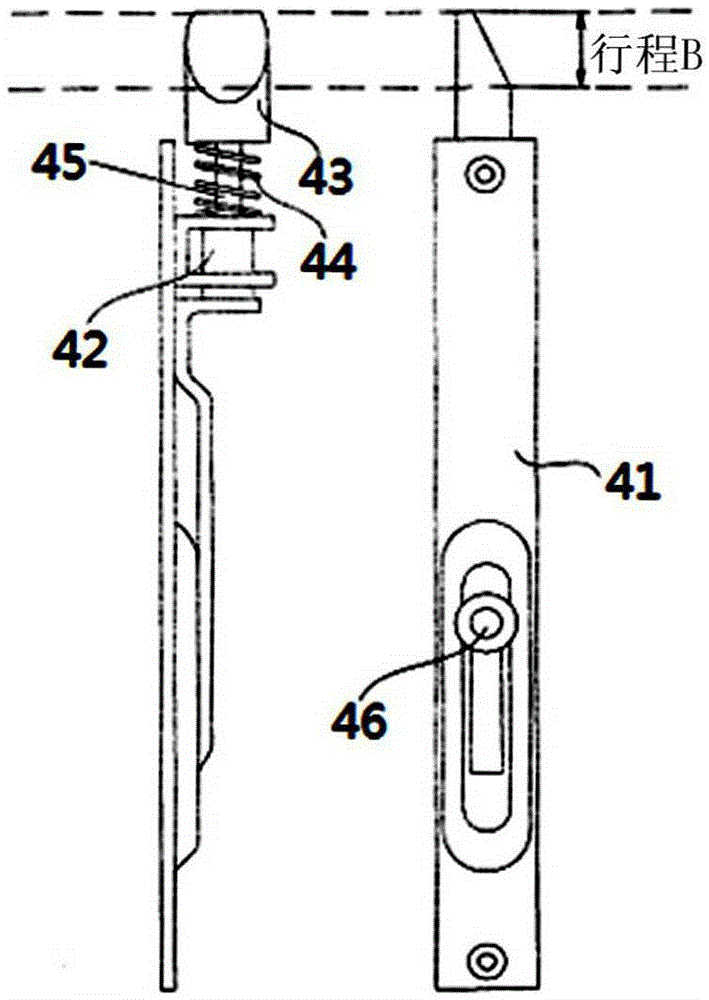

[0018] see Figure 1-3 , a sealed fire door, comprising a fire door frame 1, a fire door 2, a threshold 6, a fire door closer 7 and a fire hinge 8, the fire door 2 has two leaves, and the fire door 2 is located inside the fire door frame 1 On one side, the fireproof door 2 is also provided with a fireproof glass 3, an automatic fireproof lock 4 and a fireproof door handle 5. The fireproof glass 3 is located in the middle of the fireproof door 2, and the fireproof glass 3 is fixedly connected with the fireproof door 2. The automatic fire lock 4 is located at the top of one of the fire doors 2, the automatic fire lock 4 includes a hidden bolt body 41, and an elastic device is fixed on the hidden bolt body 1, and the elastic device includes a base 42 and a lock Tongue 43, is connected by spring 44 between described base 42 and dead bolt 43, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com