A cycle energy-saving heating system for bamboo and wood products production line

A heating system and production line technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as many fine impurities, unavailability of waste heat from heater exhaust, and high energy consumption by hot air fans. , to reduce energy consumption, accelerate adsorption and aggregation, and improve the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

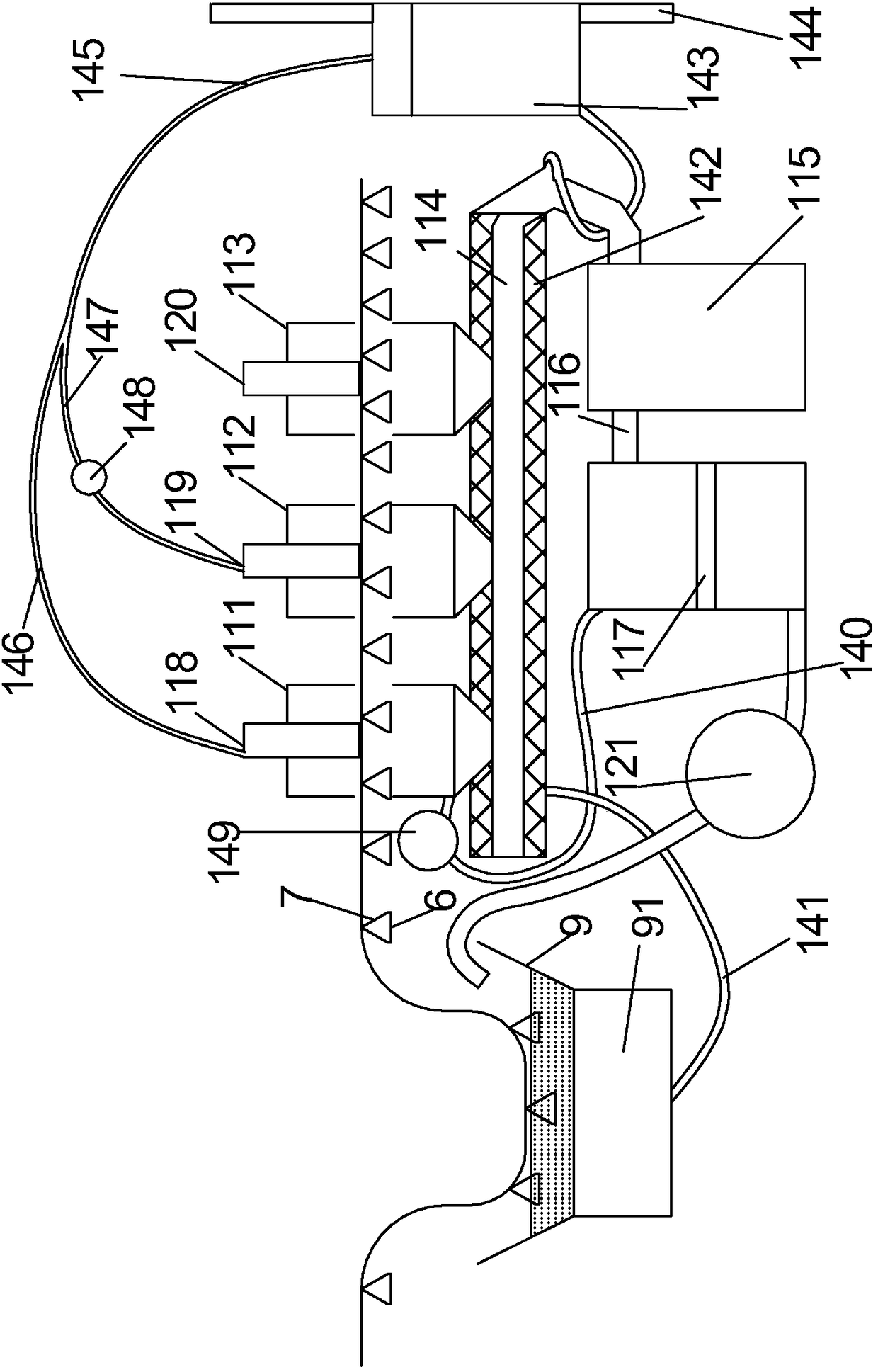

[0012] With reference to accompanying drawing, comprise conveyer belt, described conveyer belt conveys bamboo and wood products and successively through pretreatment station, oil cooking station, aftertreatment station, also is provided with recovery station on the described posttreatment station;

[0013] The cooking station is provided with a tung oil pool 9 and a heater 91 for cooking bamboo and wood products;

[0014] The post-processing station includes an oil collecting chamber 111, a hot air chamber 112, and a cold air chamber 113 which are continuously arranged for the conveyer belt to pass through; oil collecting pipes 114 are arranged at the bottoms of the oil collecting chamber 111, the hot air chamber 112, and the cold air chamber 113, The oil collecting pipe 114 is connected to the sedimentation tank 115, and the upper part of the sedimentation tank 115 is also provided with an oil outlet 116, and the oil outlet is connected to the filter tank 117; Blowing hot air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com