Numerical Optimal Design Method for the Thickness of Thermal Insulation Layer of Airborne Flight Parameter Recorder

A flight parameter and numerical optimization technology, applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve problems such as high testing costs, achieve the effects of improving efficiency, reliable basis and support, and reducing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

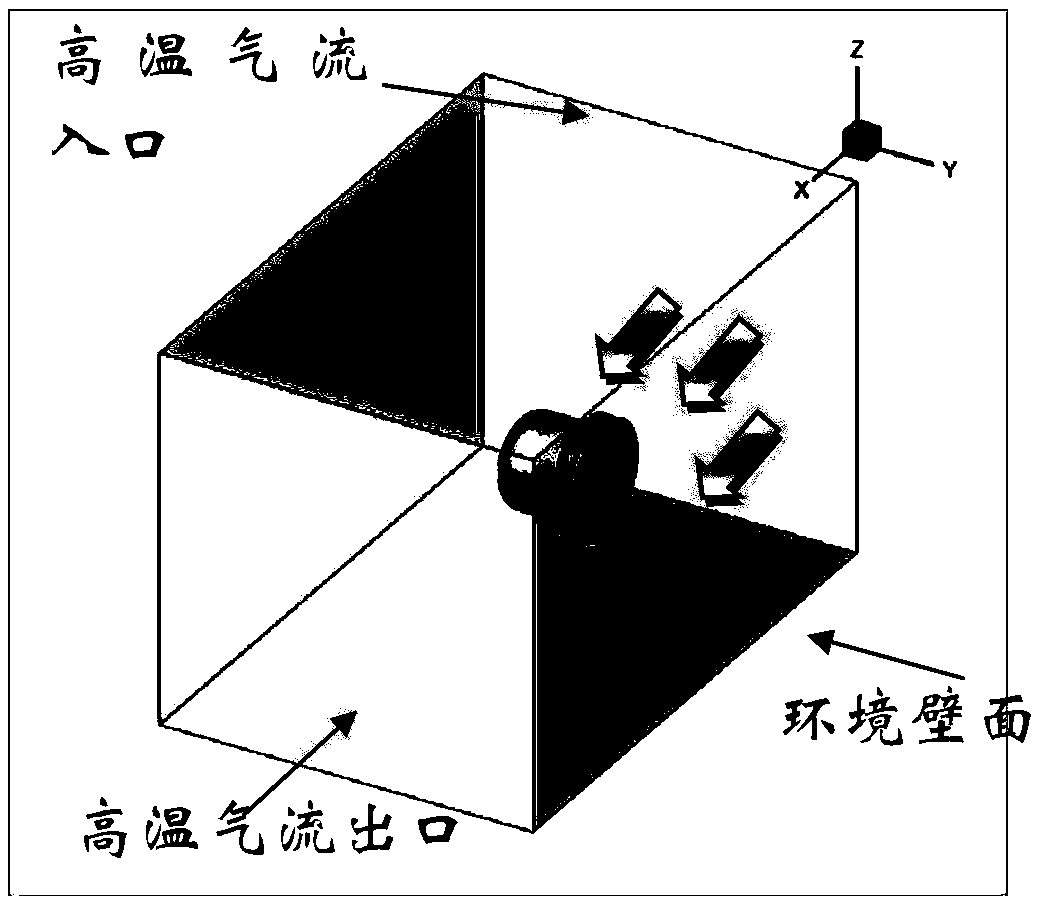

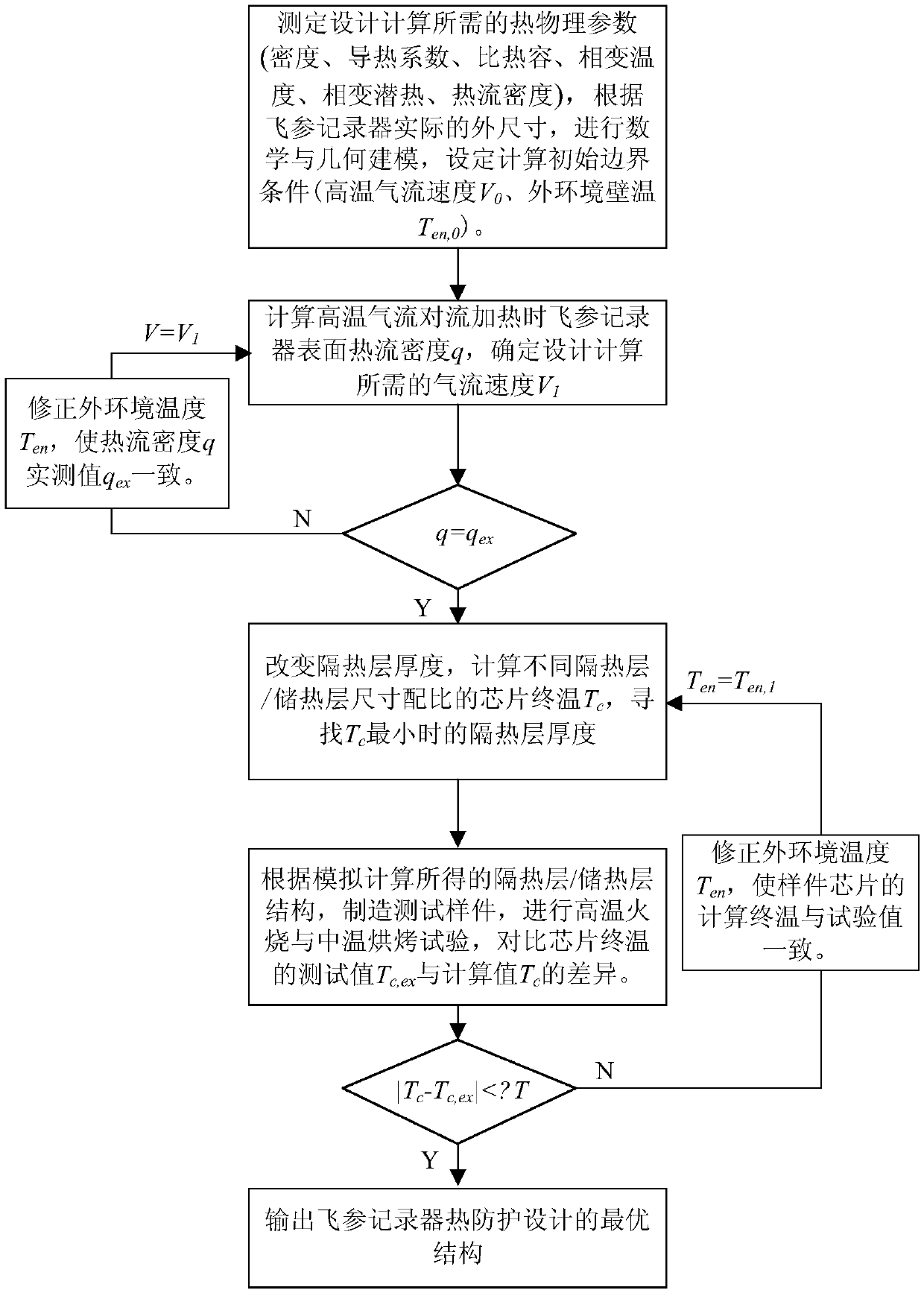

[0041] Such as image 3 Shown is the flow chart of the numerical optimization design method for the thickness of the heat insulation layer of the airborne flight parameter recorder of the present invention, and the specific implementation method is as follows:

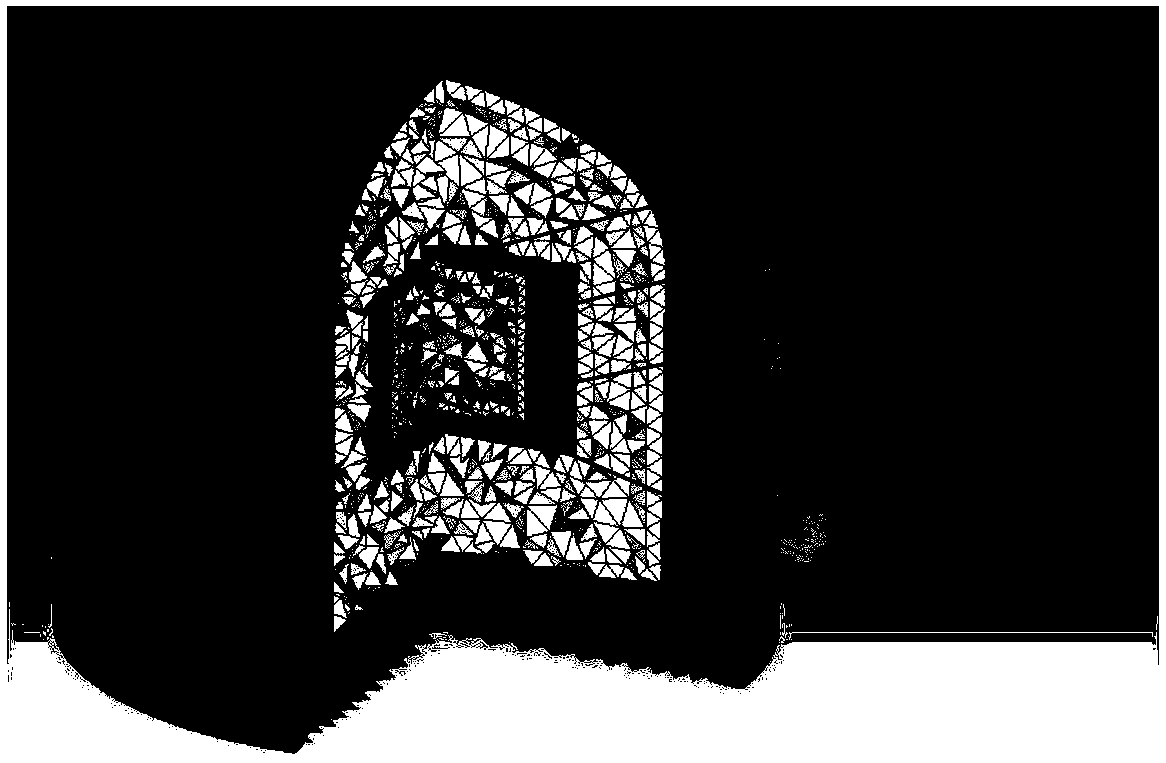

[0042] Step (1), measuring the thermophysical parameters of the outer casing 1, the heat insulation layer 3, the inner casing 2, the heat storage layer 4 and the chip 5 of the flight parameter recorder; specifically including: the heat insulation layer material within the range of normal temperature to 1100°C The thermal conductivity, density, and specific heat capacity; the density, thermal conductivity, specific heat capacity, phase transition temperature, and latent heat of phase transition of heat storage layer materials in the range from room temperature to 1100 °C; the blackness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com