Textile piece of clothing with at least one abrasion-prevention zone provided with protector elements, and method for producing same

A technology of protective articles and protected areas, applied in the field of textile and clothing, to achieve the effect of good anchoring possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

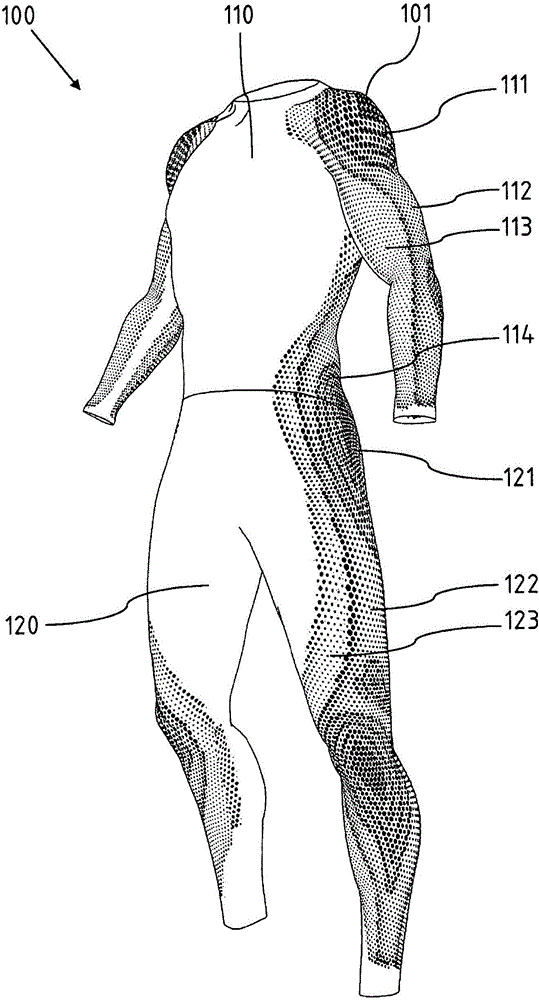

[0062] figure 1A two-piece suit 100 for road cycling is shown. The first garment is configured as upper portion 110 . Particularly risky areas are the shoulders and the upper torso laterally. A scratch protection zone 111 with a particularly large guard element 101 is formed in the shoulder region. Extending along the arm is a second scratch protection zone 112 with a medium sized guard element. Smaller protective elements are arranged in the third scratch protection area 113 on the back and inside of the arm (the back and inside of the arm are less at risk when cycling). Furthermore, a scratch protection zone 114 is formed in the back region and the hip region.

[0063] The upper part 110 is supplemented by trousers 120 , on which the scratch protection zones 121 , 122 , 123 are likewise formed, in particular in the region on the outside of the legs up to the buttocks.

[0064] Thus, in the combination of the two garments 110, 120, a continuous scratch protection zone ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap