Production line monitoring device, production line monitoring program, and production line monitoring method

A monitoring device and production line technology, applied in the direction of program control, electrical program control, test/monitoring control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

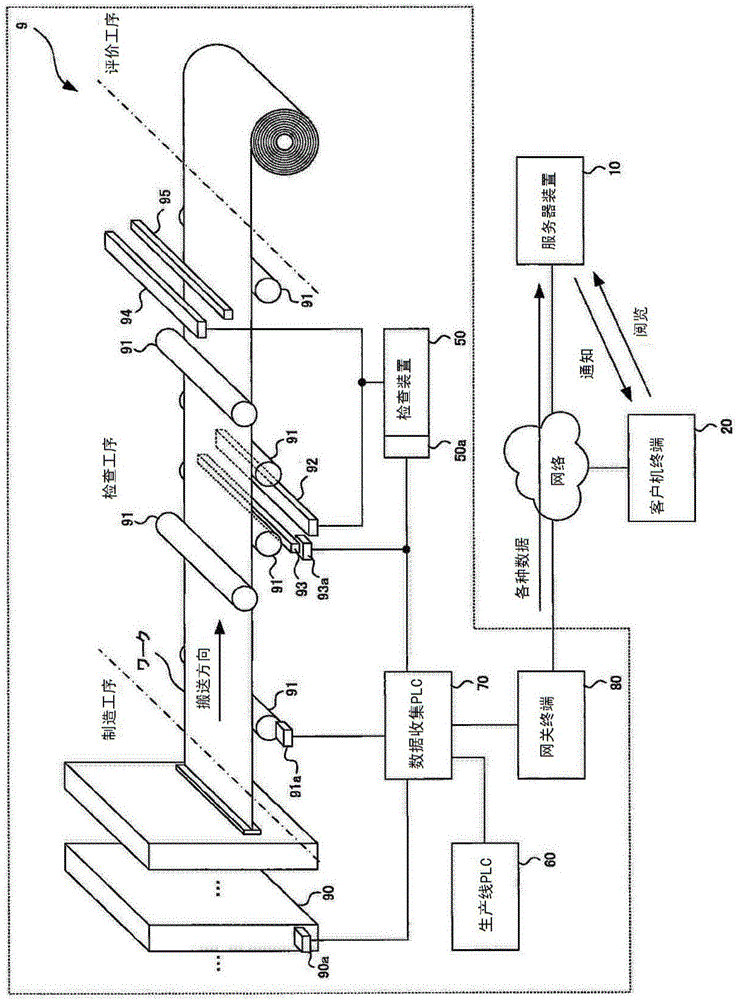

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 The overall configuration of the production line monitoring system of this embodiment will be described. figure 1 It is a schematic diagram of the production line monitoring system of this embodiment.

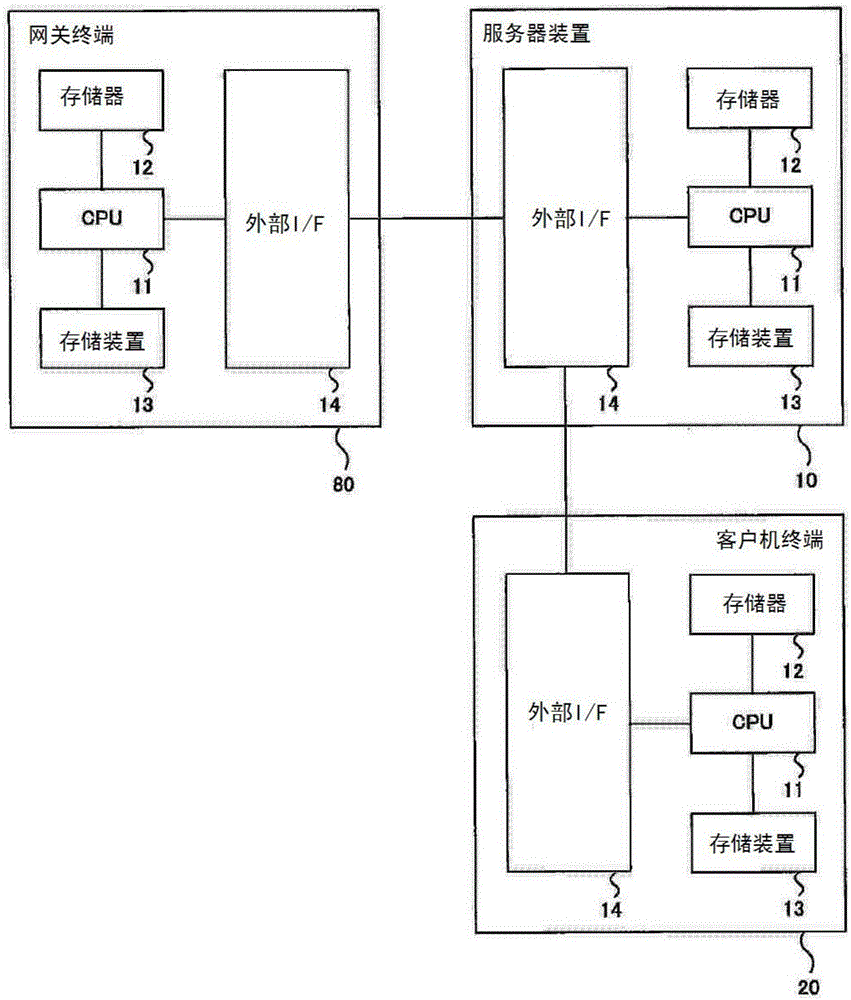

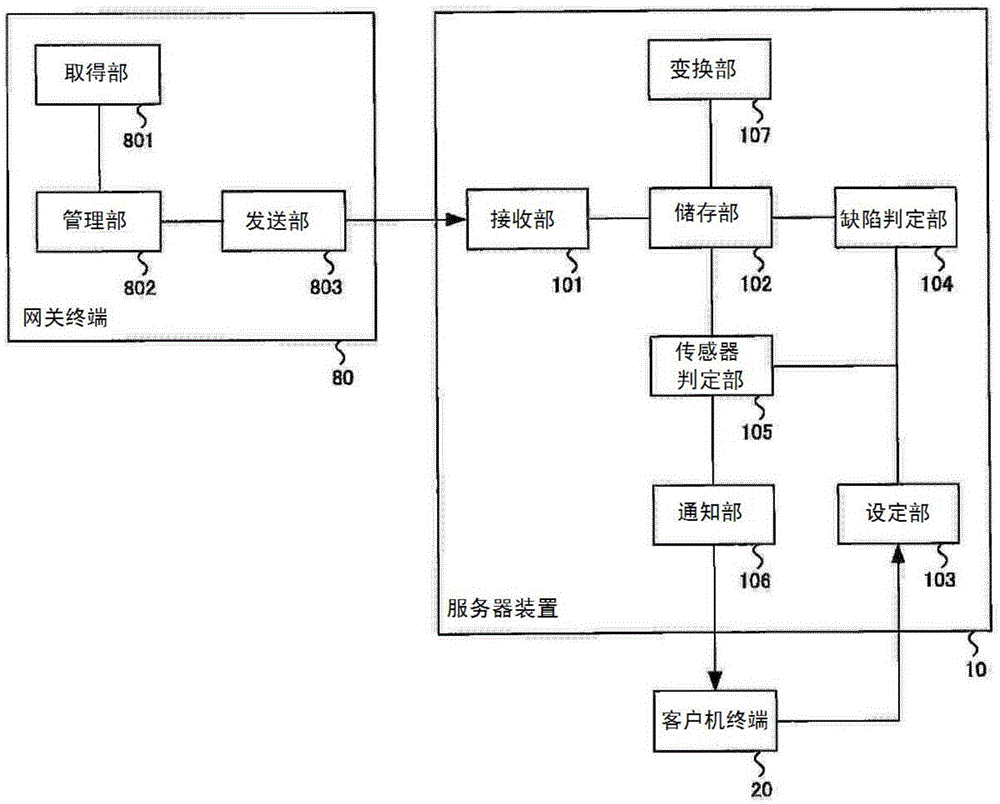

[0017] Such as figure 1 As shown, the production line monitoring system according to this embodiment includes a production line 9, an inspection device 50, a production line PLC (Programmable Logic Controller: Programmable Logic Controller) 60, a data collection PLC 70, and a gateway terminal 80 as a structure installed at a manufacturing site. , In addition, as a configuration installed in a remote place, a server device 10 and a client terminal 20 are provided. In addition, the server device 10 and the client device 20 are installed in mutually different locations.

[0018] In this embodiment, the production line 9 has a plurality of manufact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com