A kind of preparation method of light plant life floating bed

A light-weight, floating bed technology, applied in the field of preparation of light-weight vegetated floating beds, can solve problems such as limiting the size of floating beds, affecting the effect of water body improvement, secondary pollution, etc., achieving high buoyancy, good resistance to wind and wave impact, and low crushing index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a lightweight plant-growing floating bed is prepared by the following steps:

[0029] 1) Weigh in parts by weight: 90 parts of aluminum powder and 10 parts of anhydrous ethanol, stir evenly, pelletize into balls, select pellets with a particle size of 3-6mm to the coating machine, and spray soluble starch evenly through air atomization , To form a soluble starch film on the surface of the particles to obtain aluminum powder balls;

[0030] 2) Weigh in parts by weight: 30 parts of pumice powder, 15 parts of cement, 35 parts of aluminum powder balls, and 20 parts of water. Stir evenly, granulate and shape to obtain a sphere with a diameter of 35mm. Cure for 90 minutes at 45°C to obtain Foam light ball;

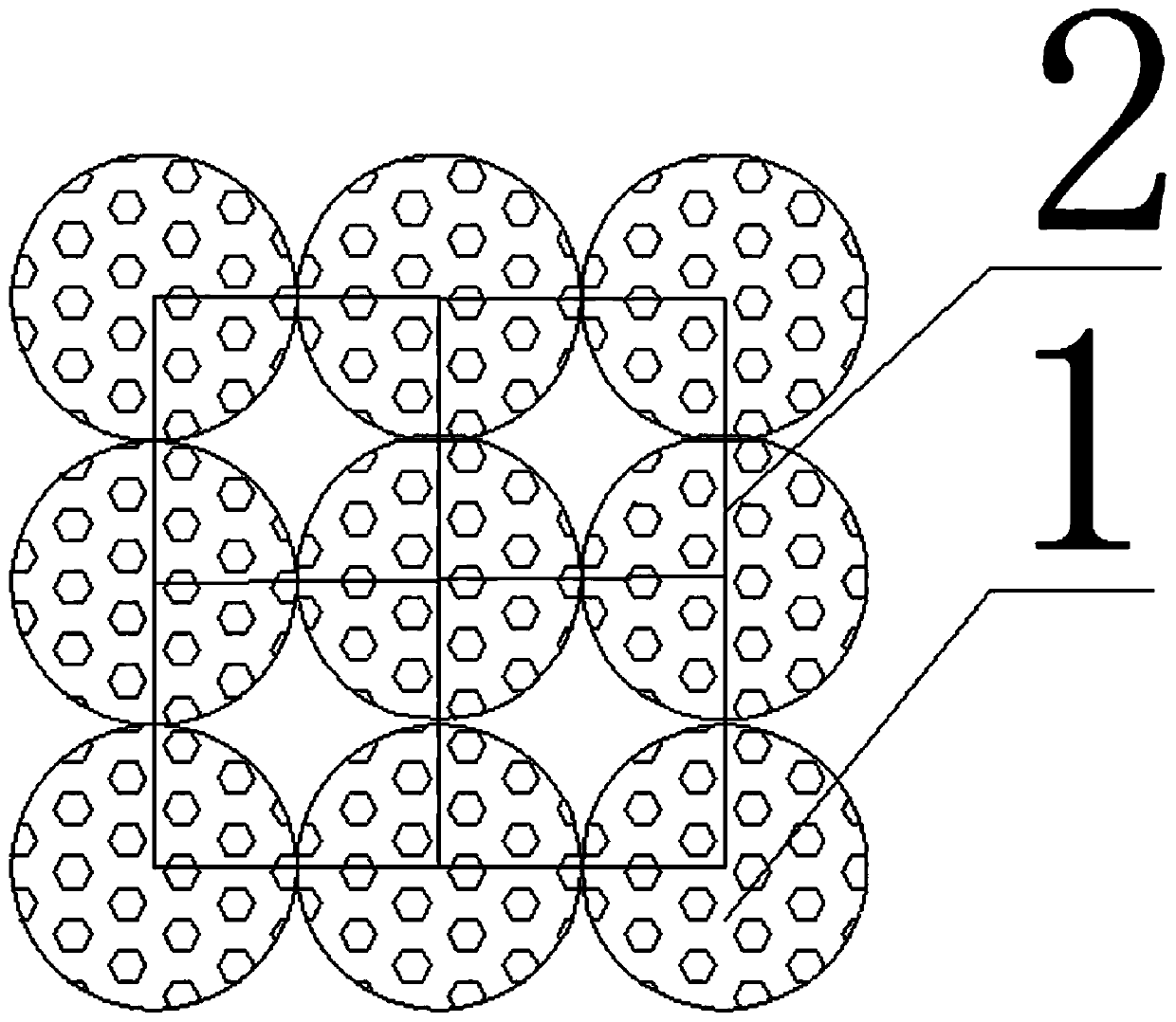

[0031] 3) Drill the foamed lightweight ball through the center of the ball to drill three vertical through holes;

[0032] 4) Pass the rope through the through hole and connect the foamed light ball into a cube in a 3*3*3 way to obtain a lightweight plant...

Embodiment 2

[0039] A preparation method of a lightweight plant-growing floating bed is prepared by the following steps:

[0040] 1) Weigh in parts by weight: 94 parts of aluminum powder and 7 parts of absolute ethanol, stir evenly, pelletize into balls, select the pellets with a particle size of 3-6mm to the coating machine, and spray soluble starch evenly through air atomization , To form a soluble starch film on the surface of the particles to obtain aluminum powder balls;

[0041] 2) Weigh in parts by weight: 40 parts of pumice powder, 10 parts of cement, 30 parts of aluminum powder balls, and 25 parts of water. Stir evenly, granulate and form to obtain a ball with a diameter of 25mm. Cured at 70°C for 60 minutes, get Foam light ball;

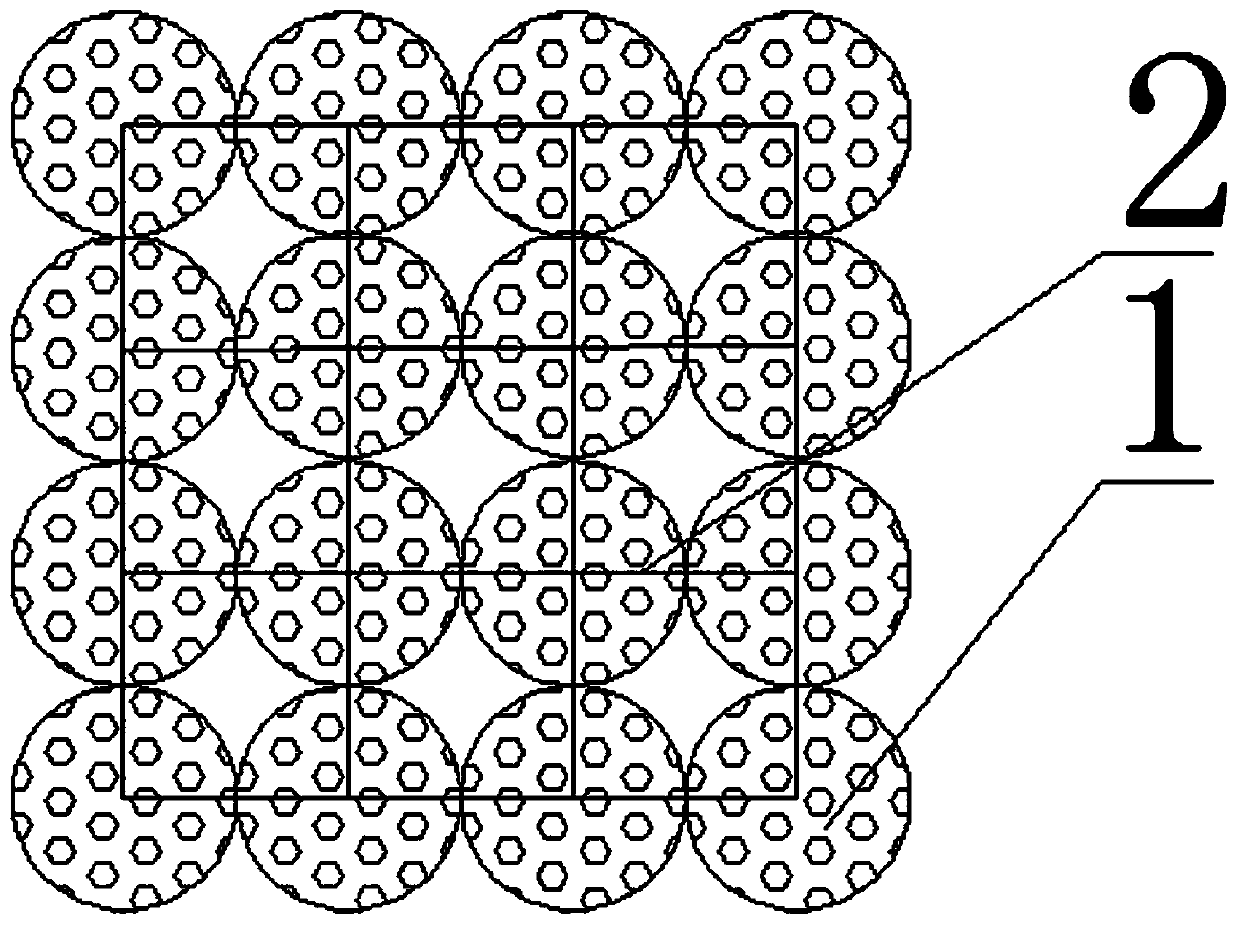

[0042] 3) Drill the foamed lightweight ball through the center of the ball to drill three vertical through holes;

[0043] 4) Pass the rope through the through hole to connect the foamed lightweight ball into a cube to obtain a lightweight planted floating bed...

Embodiment 3

[0051] A preparation method of a lightweight plant-growing floating bed is prepared by the following steps:

[0052] 1) Weigh in parts by weight: 97 parts of aluminum powder and 3 parts of absolute ethanol, stir evenly, pelletize into balls, select the pellets with a particle size of 3-6mm to the coating machine, and spray the soluble starch evenly through air atomization , To form a soluble starch film on the surface of the particles to obtain aluminum powder balls;

[0053] 2) Weigh in parts by weight: 50 parts of pumice powder, 5 parts of cement, 25 parts of aluminum powder balls, and 30 parts of water. Stir evenly, granulate and shape to obtain a sphere with a diameter of 20mm. After curing at 90°C for 30 minutes, Foam light ball;

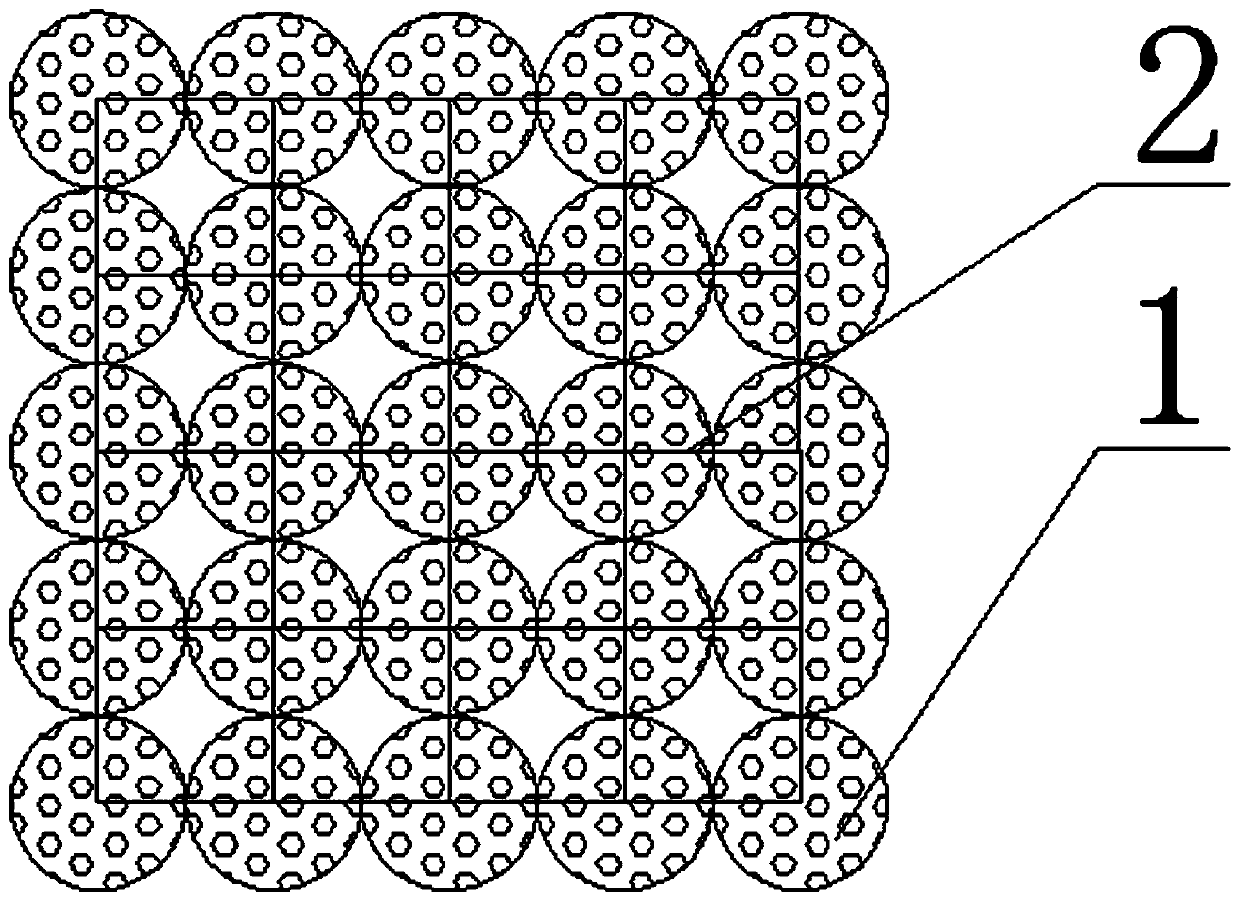

[0054] 3) Drill the foamed lightweight ball through the center of the ball to drill three vertical through holes;

[0055] 4) Pass the rope through the through hole to connect the foamed lightweight ball into a cube to obtain a lightweight planted flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap