Hydraulic driven automatic self-cleaning filter

A self-cleaning filter, hydraulic drive technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc. easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

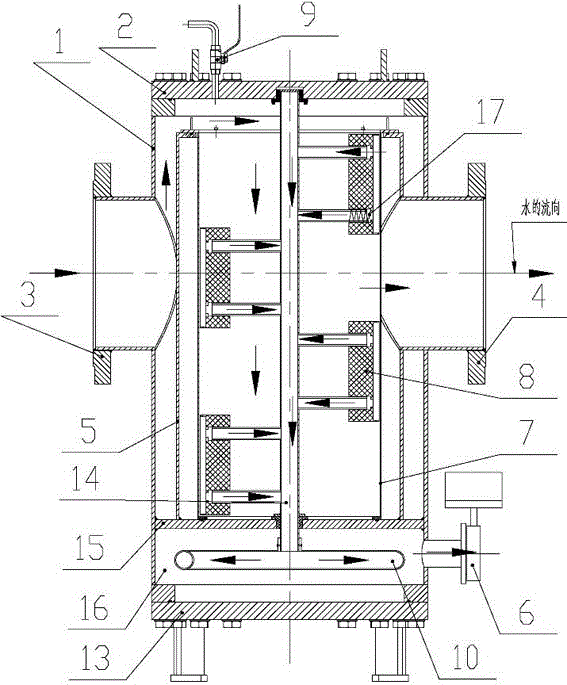

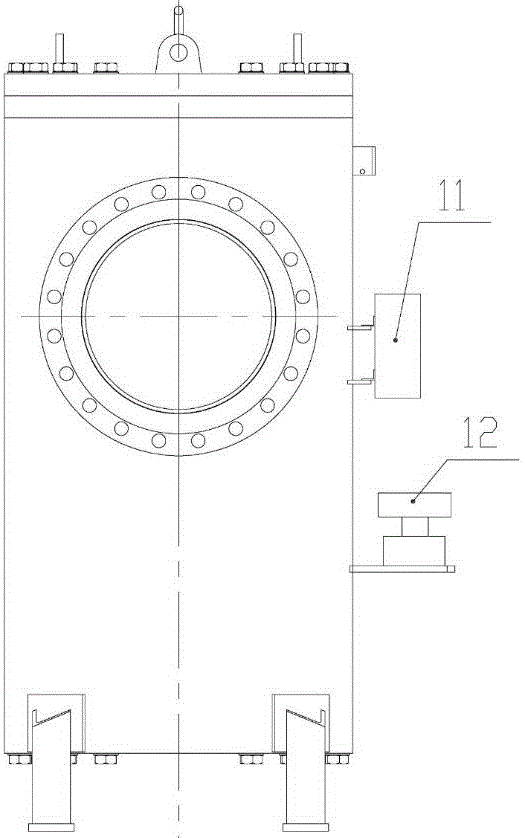

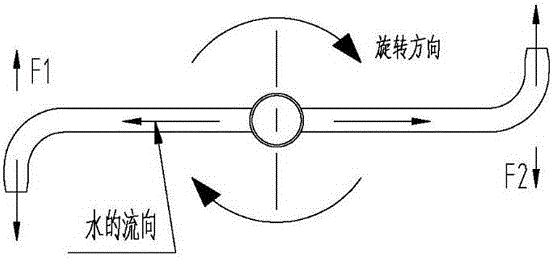

[0020] As shown in the figure, the specific implementation method is as follows:

[0021] A hydraulically driven fully automatic self-cleaning filter, including a filter body 1, the filter body 1 cooperates with the upper head 2 installed at its upper end and the lower head 13 installed at its lower end to seal the inner surface of the filter body 1 The cavity is sealed into a sealed chamber, and a partition 15 is fixed in the sealed chamber. The partition 15 divides the sealed chamber into a filter chamber and a sewage discharge chamber 6 that are isolated from each other. An inner cylinder 5 is installed in the filter chamber, and the inner cylinder 5 divides the filter chamber It is divided into two parts, the inner cavity of the inner cylinder and the outer cavity of the inner cylinder. The inner cavity of the inner cylinder is connected with the water outlet 4, the outer cavity of the inner cylinder is connected with the water inlet 3, and the inner cylinder 5 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com