Tracing method for cast production information and prefix of tracing characteristics of casting production information

A technology for producing information and castings, applied in the direction of casting molding equipment, manufacturing tools, tools, etc., can solve the complex process and difficult to analyze from many possible factors; such as a pair of molds, a certain date, a certain shift, A certain worker, difficult to trace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

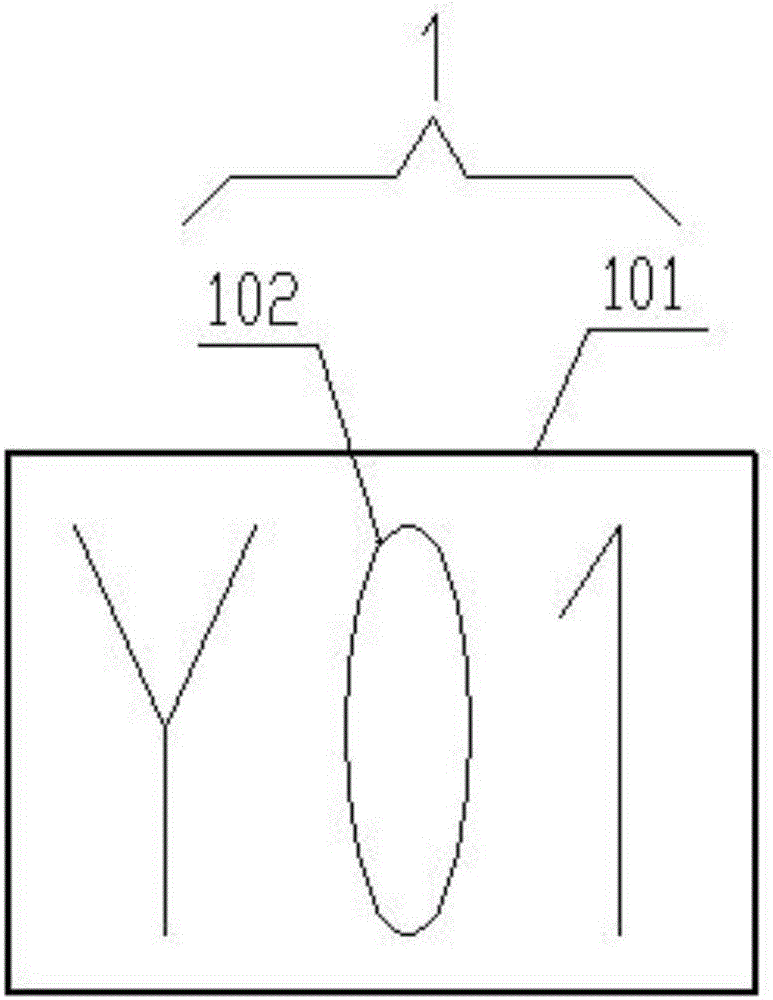

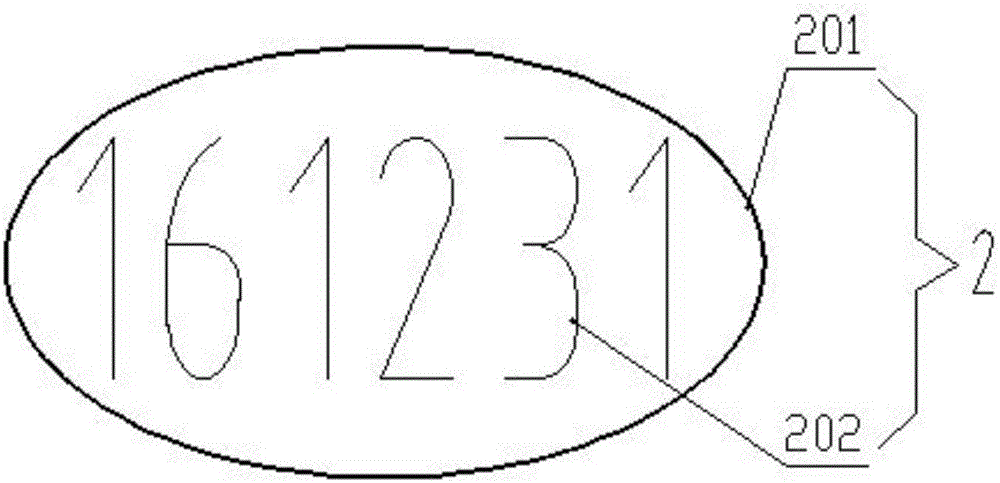

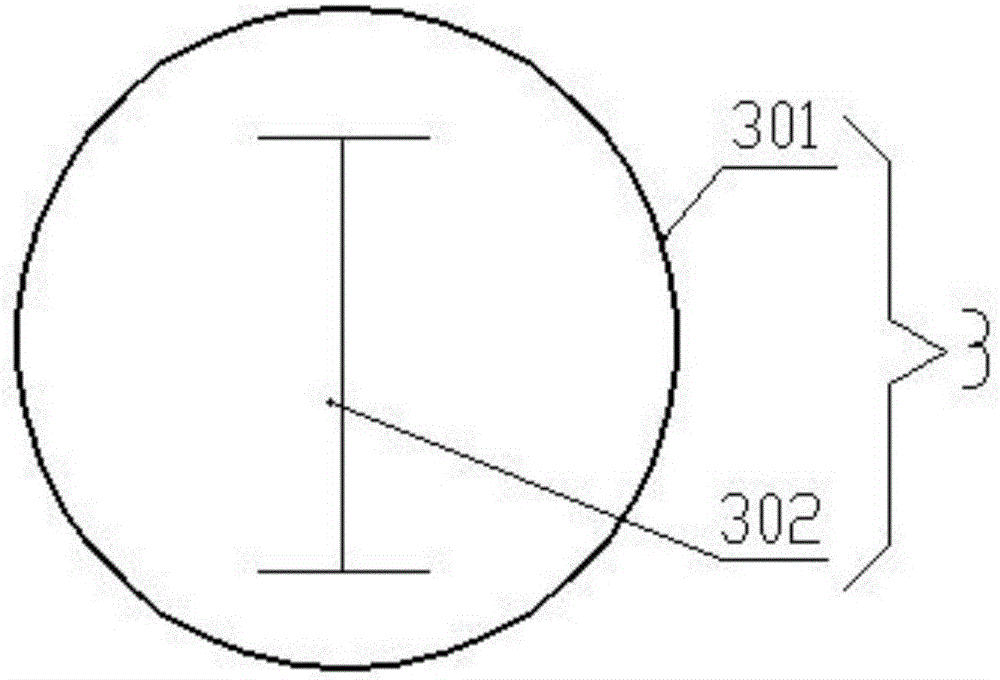

[0029] A method for tracing the production information of castings. The inner wall of the mold cavity is provided with recessed or prominent traceability features representing the production information of castings. The traceability features include mold code features representing the mold, casting date features representing the casting date, The shift characteristics representing the casting shift, and the casting operator code characteristics representing the casting workers; when the above-mentioned molds are used to cast the parts, the corresponding imprints of the above-mentioned various tracea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com