Device for clamping multiple workpieces

A clamping device and multi-workpiece technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as insufficient clamping force, complete suspension, tool breakage, etc., to ensure clamping stability and guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

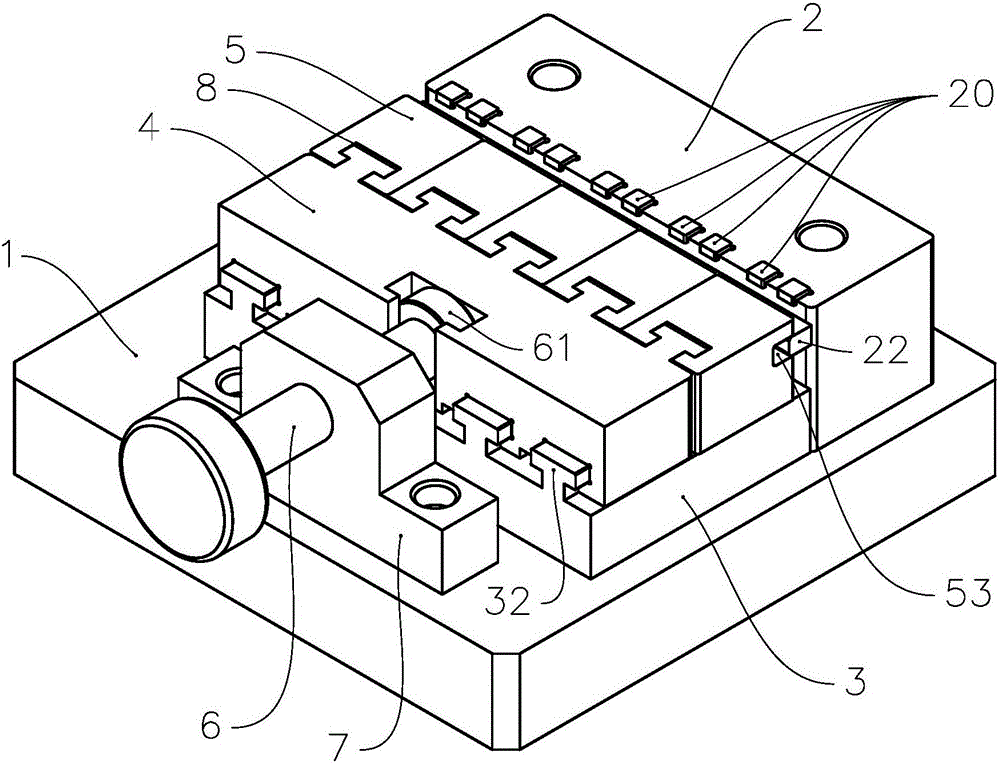

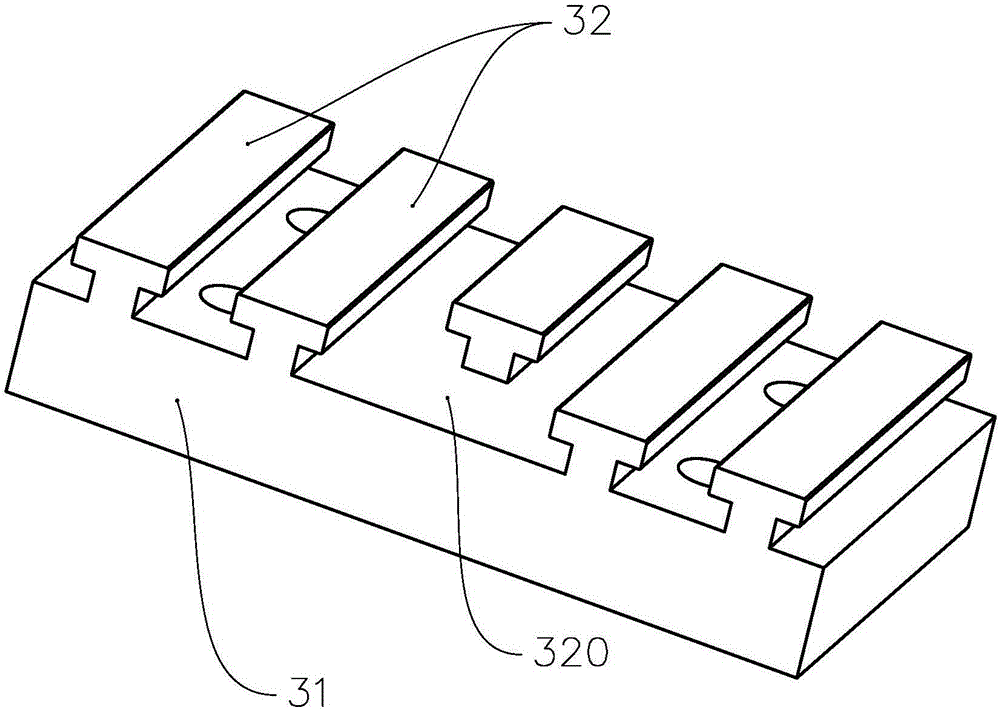

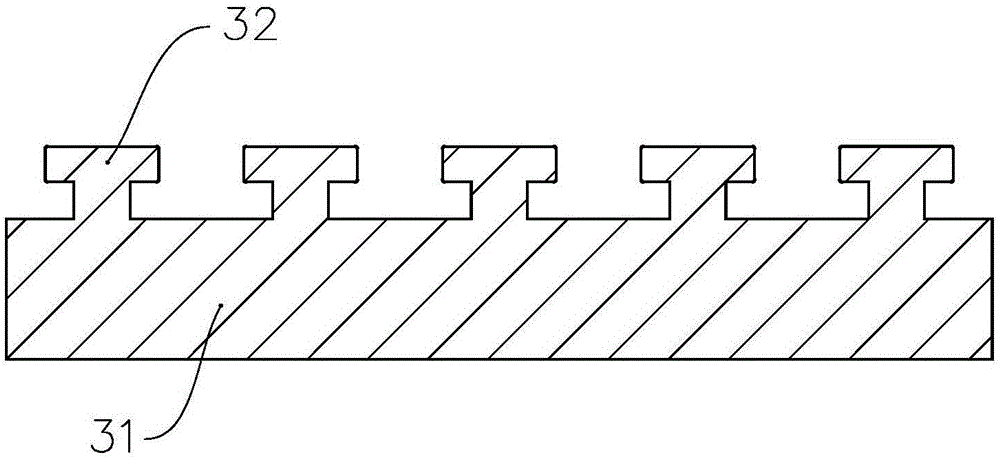

[0036] see figure 1 , figure 1 It is a structural diagram of Embodiment 1 of the multiple workpiece clamping device of the invention. The multi-workpiece clamping device includes a base plate 1, a fixing seat 2 and a clamping device, and the clamping device includes a slide rail 3, a first slider 4, a second slider 5, a screw 6 and a bracket 7, and the fixing seat 2 and the clamping device Set on base plate 1. The slide rail 3 is arranged between the fixed seat 2 and the bracket 7, the first slide block 4 and the second slide block 5 are slidably arranged on the slide rail 3, the first slide block 4 is connected with a plurality of second slide blocks 5, The second slider 5 is located between the first slider 4 and the fixing base 2 . Screw rod 6 is provided with external thread, and erected on the support 7, is provided with screw hole on the support 7, is provided with internal thread in the screw hole, and screw rod 6 is threadedly matched with support 7, and one end of ...

Embodiment 2

[0045] see Figure 15 , Figure 15 It is a structural diagram of Embodiment 2 of the multiple workpiece clamping device of the present invention. In this embodiment, the multiple workpiece clamping station includes a bottom plate 100 , a fixing seat 200 , a clamping assembly 300 , a clamping assembly 400 , a clamping assembly 500 and a clamping assembly 600 . The structures of the clamping assembly 300 , the clamping assembly 400 , the clamping assembly 500 and the clamping assembly 600 are the same as those of the clamping assembly in Embodiment 1, and will not be repeated here. The clamping assembly 400 , the clamping assembly 500 and the clamping assembly 600 are arranged symmetrically on both sides of the fixing base 200 . A plurality of workpiece clamping positions and receiving blocks are arranged symmetrically on the fixed seat 200 .

[0046] The advantage of using the multi-workpiece clamping device of the present invention is: turning the screw rod drives the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com