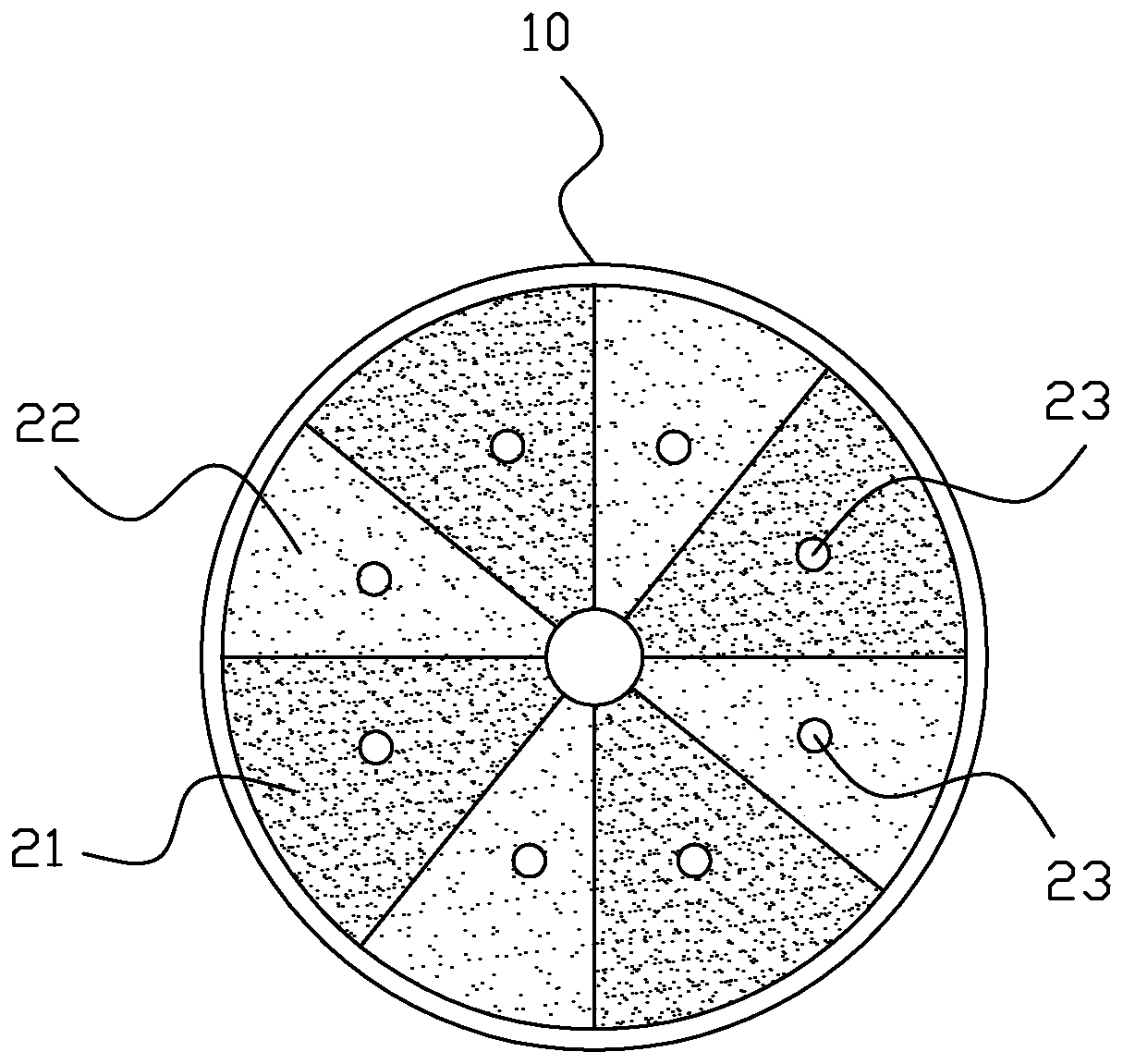

A camera glass panel polishing brush and polishing method thereof

A glass panel and camera technology, which is applied to metal processing equipment, manufacturing tools, and wheels of flexible working parts, etc., can solve the problems of rainbow in camera effects, poor flat crystal effect of glass panels, and affected surface effects of glass panels. Problems such as damage, to achieve the effect of improving the flat crystal processing yield, improving the flat crystal effect and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

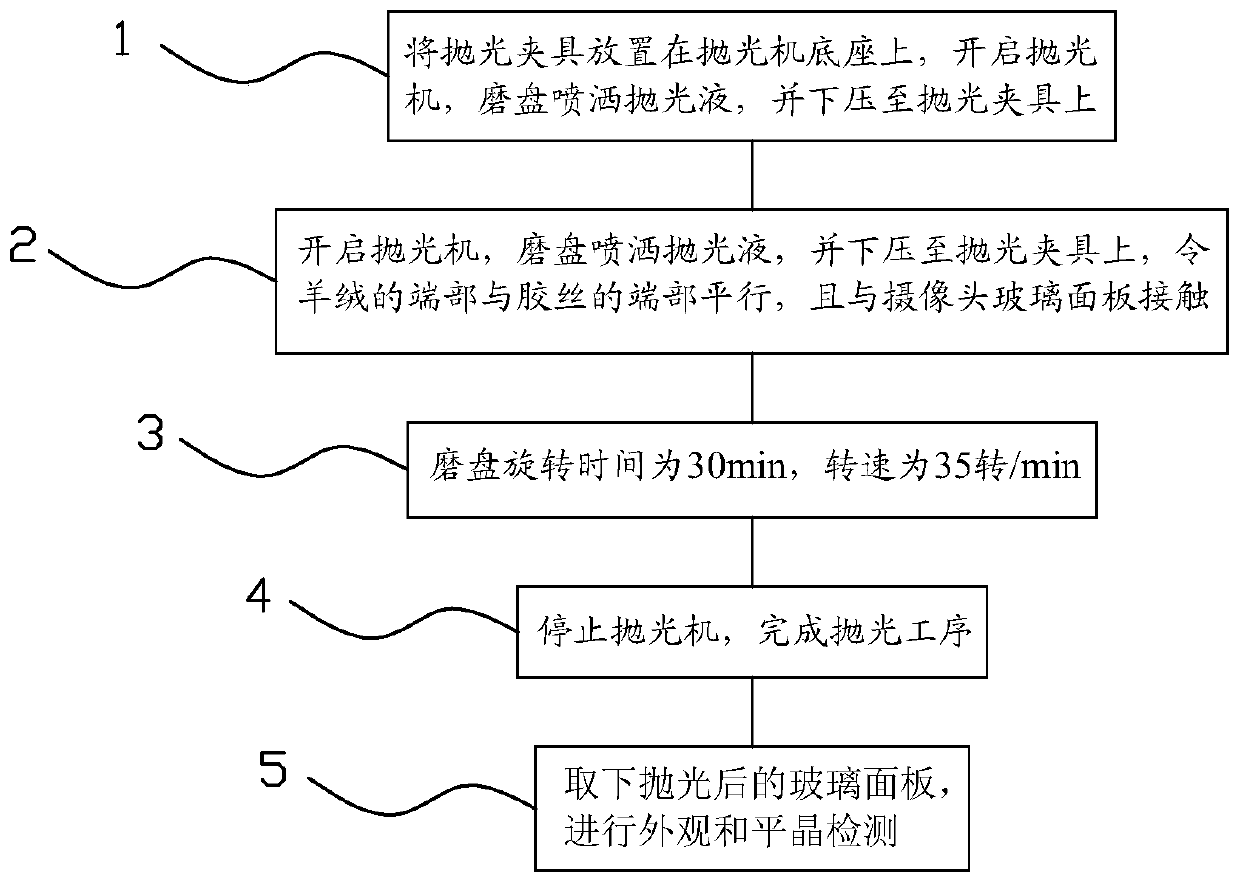

Embodiment 1

[0034] The experimental brush is a rubber wire brush, the diameter of the rubber wire is 0.3mm, and the length is 35mm. In the polishing method, the pressing pressure of the grinding disc is 280kg, the rotation speed is 30rpm, and the rotation time is 35min. The appearance yield and flat crystal detection yield experiment The data looks like this:

[0035] Experiment number Sampling quantity Appearance Qualified Quantity Appearance yield Qualified quantity of flat crystal Flat wafer yield 1 50 1 2% 0 0% 2 50 0 0% 0 0% 3 50 1 2% 1 2%

Embodiment 2

[0037] The experimental brush is a cashmere brush, the cashmere diameter is 3mm, and the length is 30mm. In the polishing method, the pressing pressure of the grinding disc is 280kg, the rotation speed is 30rpm, and the rotation time is 35min. The experimental data of appearance yield and flat crystal inspection yield are as follows Show:

[0038] Experiment number Sampling quantity Appearance Qualified Quantity Appearance yield Qualified quantity of flat crystal Flat wafer yield 1 50 34 68% 16 32% 2 50 32 64% 18 36% 3 50 33 66% 17 34%

Embodiment 3

[0040] The experimental brush is a mixed brush of cashmere and rubber silk. The diameter of cashmere is 3mm, the length is 30mm, the diameter of rubber silk is 0.3mm, and the length is 35mm. 35 minutes, the experimental data of appearance yield and flat crystal inspection yield are as follows:

[0041] Experiment number Sampling quantity Appearance Qualified Quantity Appearance yield Qualified quantity of flat crystal Flat wafer yield 1 50 42 84% 35 70% 2 50 44 88% 34 68% 3 50 43 86% 36 72%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com