A kind of glazing method with stable temperature glazing of glaze slurry

A technology of glaze slurry and glazing, which is applied in the field of stable glazing process, which can keep the glaze slurry at a constant temperature, and can solve the problems of unstable glaze amount, temperature rise, and high viscosity of glaze slurry, etc., to solve the thixotropy of glaze slurry , maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

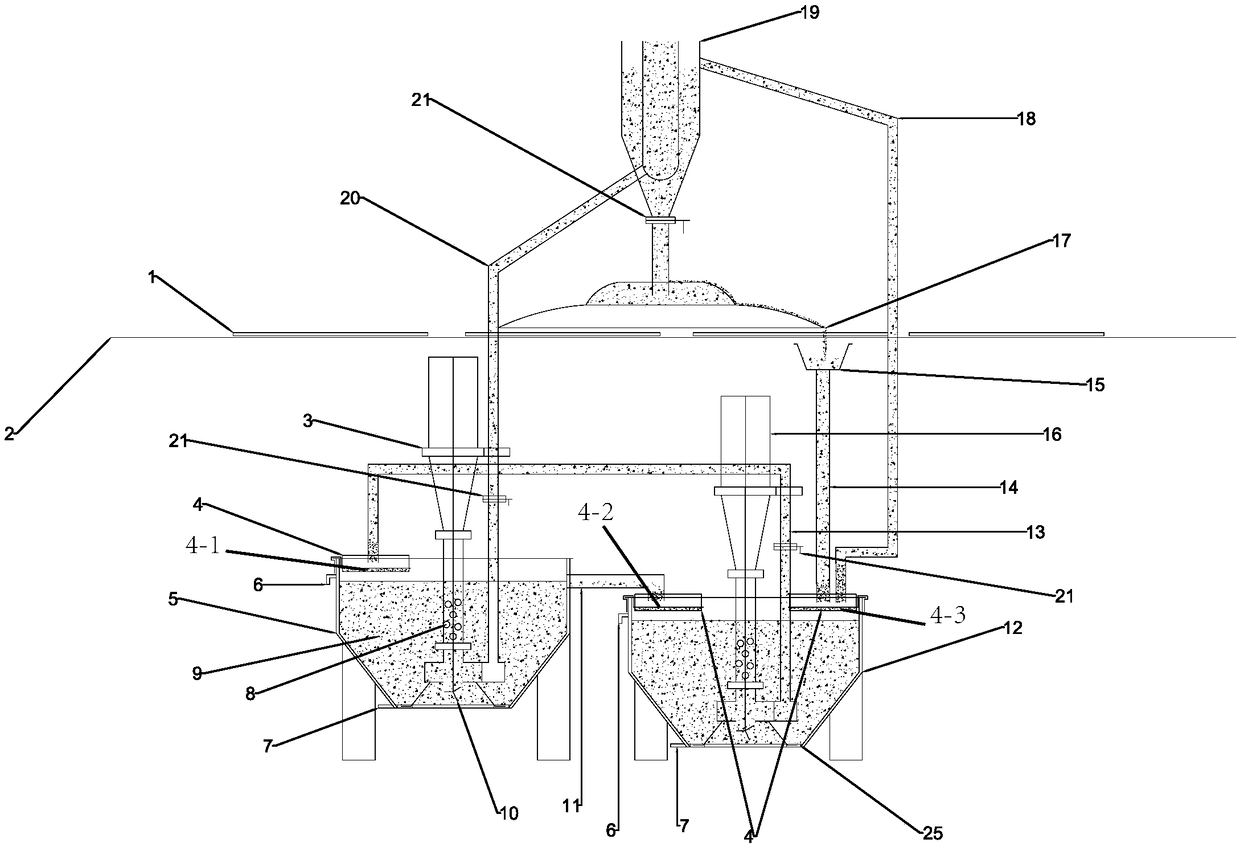

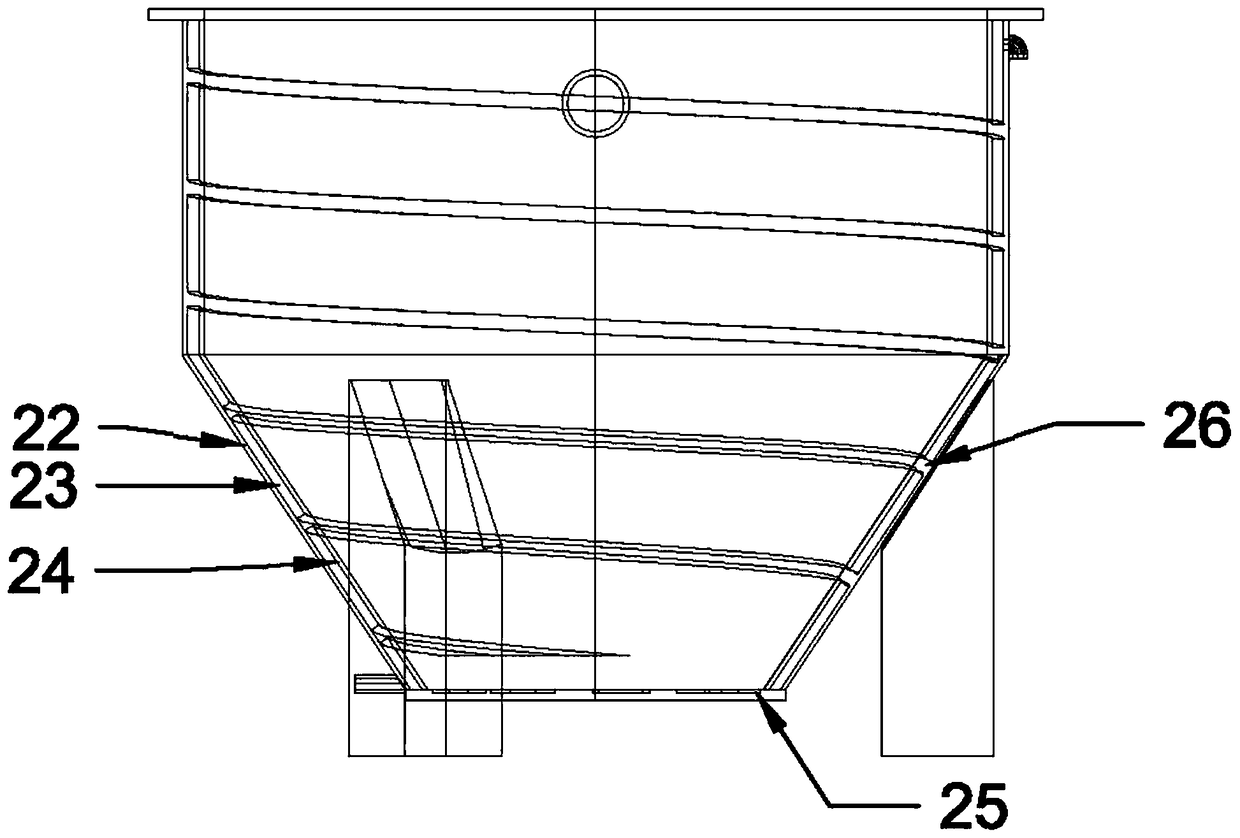

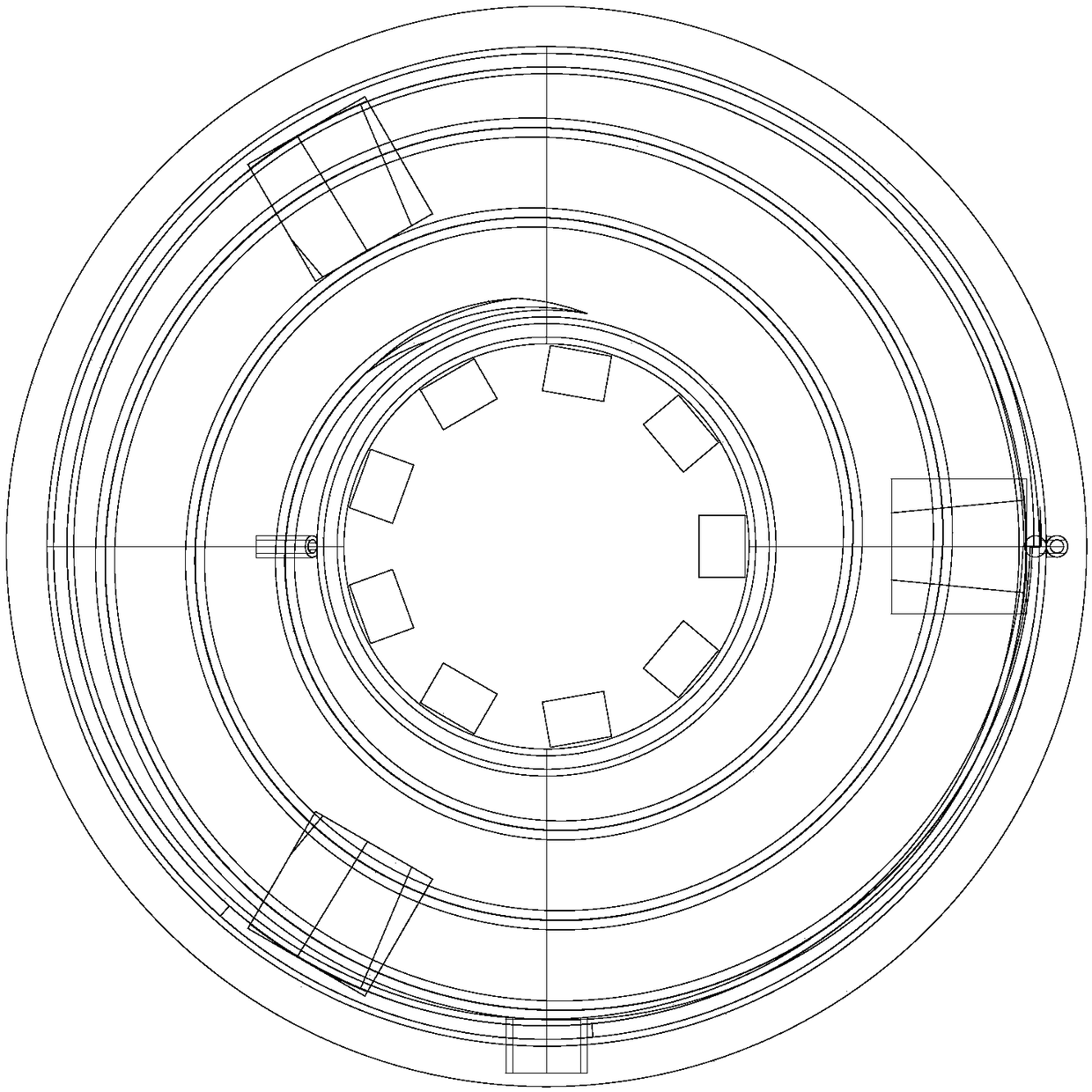

[0043] Such as Figure 1 to Figure 4 As shown, it discloses a combined glaze device, comprising a main glaze vat 5, a main glaze vat glaze pump 3, a main glaze pump glaze delivery pipe 20, a glaze pouring hopper 19, a glaze return pipe 18, a glaze pouring bell 17, a set The glaze pipe 14, the main glaze vat glaze pump 3 has a first discharge hole 8-1, and a glaze collection hopper 15 is connected to the glaze collection pipe 14. The key improvement of this scheme is that it also includes the auxiliary glaze vat 12 and its matching The auxiliary glaze vat glaze pump 16, the auxiliary glaze vat glaze pump 16 has the second discharge hole 8-2; it includes the auxiliary glaze pump glaze delivery pipe 13, the inlet end is set in the auxiliary glaze vat 12, and the outlet end extends to the main glaze vat 5. The glaze slurry 9 in the auxiliary glaze vat 12 is transported into the main glaze vat 5 through the auxiliary glaze vat glaze pump 16 and the auxiliary glaze pump glaze deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com