Boat trailer of automatic centering structure

An automatic centering and boating technology, which is applied to motor vehicles, vehicles used for freight, and goods transport vehicles, etc., can solve problems such as difficult to maintain the angle of centering, and achieve improved stability, reduced damage rate, and reduced friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

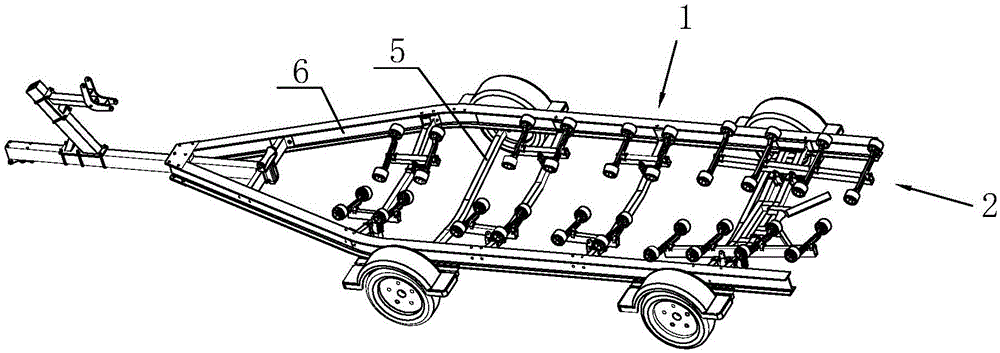

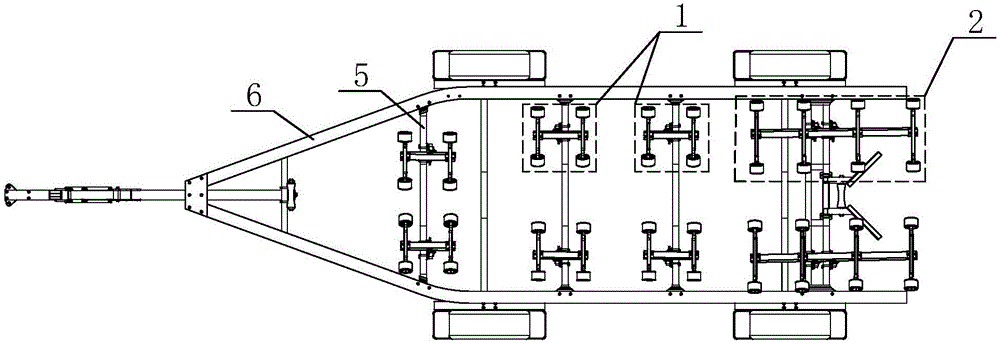

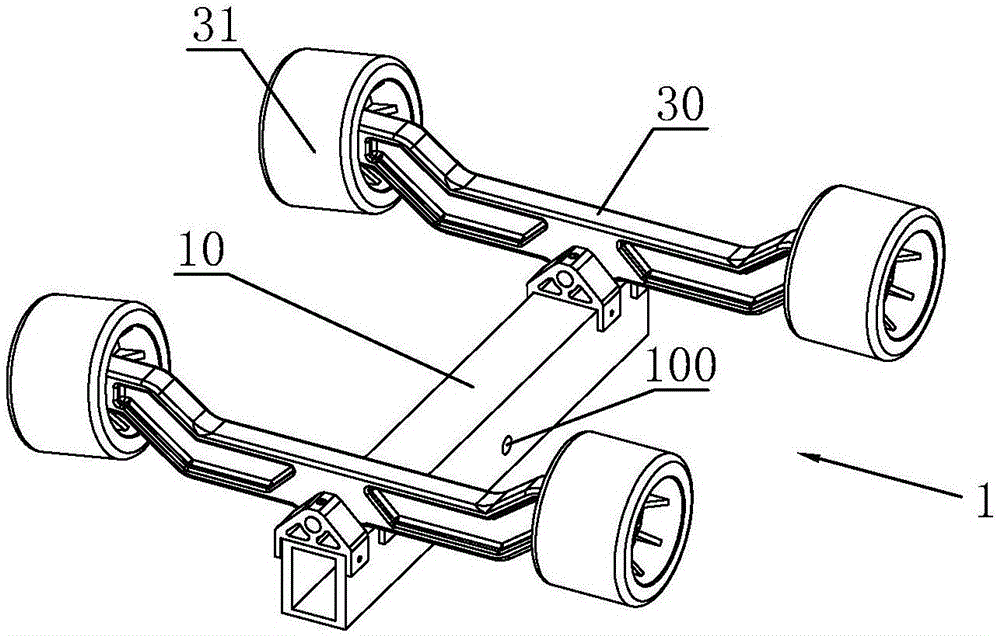

[0045] Such as Figures 1 to 13 A boat trailer with an automatic centering structure shown includes a vehicle frame, wheels, load-bearing roller device 1 , guide roller device 2 , V-shaped guide plate 7 located at the rear of the trailer, and a lifting wheel 70 .

[0046]The frame includes a side frame 6 and a support frame 5. The two ends of the support frame 5 are fixed to the inner surface of the side frame 6. The horizontal ends of the middle part of the support frame 5 tilt up to form a "﹝" shape, and the load-bearing roller device 1 passes through the first pole. It is fixed on the inclined two ends of the support frame 5 , and the guide roller device 2 is fixed on the inclined two ends of the support frame 5 through the second support rod. By obliquely placing the guide roller device and load-bearing roller device, it forms a V-shaped support surface, which cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com