Heating plate cable protecting device

A protection device and heating plate technology, applied in packaging, transportation, packaging, closing, etc., can solve problems affecting normal use, cable breakage, and affecting heating effects, etc., and achieve the effect of simple operation, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

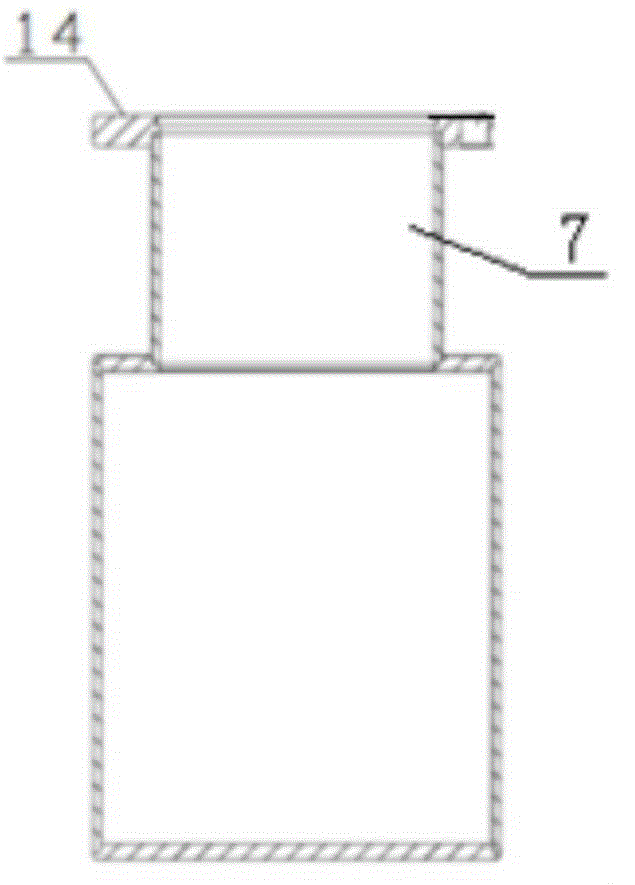

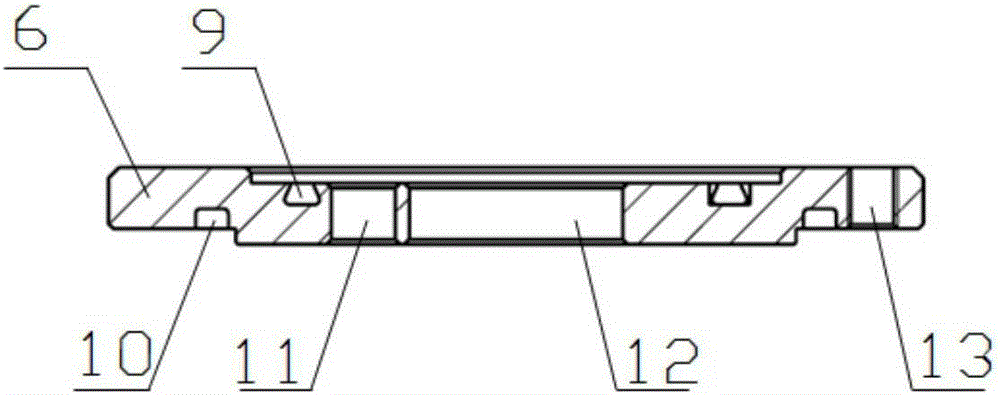

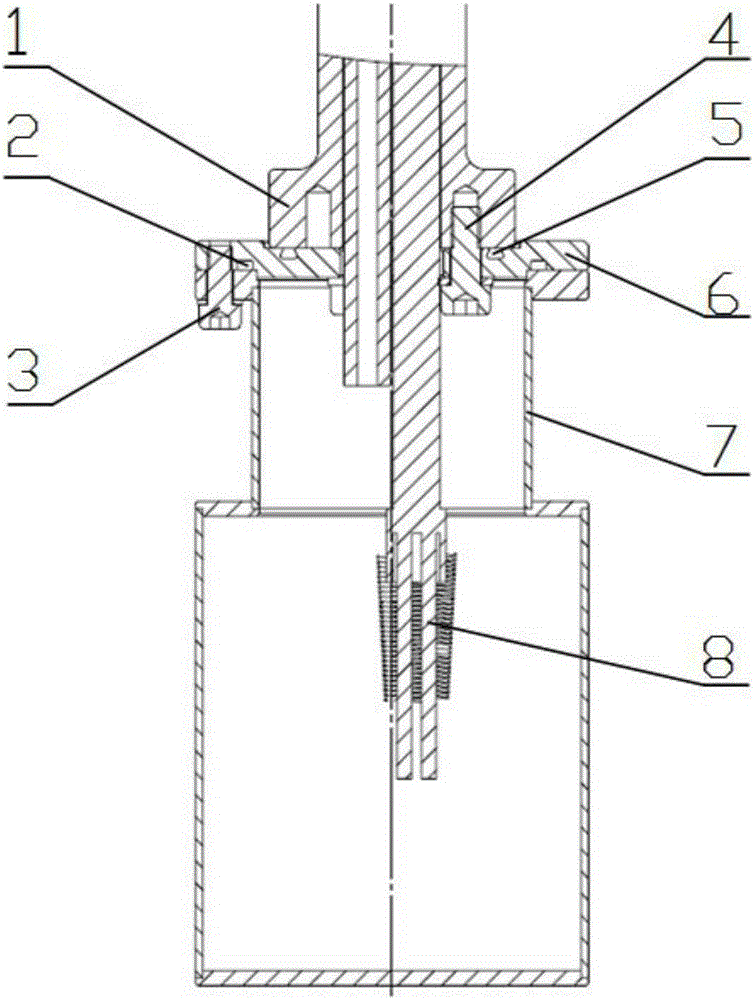

[0016] refer to Figure 1-3 , the heating plate cable protection device, including the cable protection sleeve 7. A sealing ring 2 between the connecting piece and the protective sleeve and a sealing ring 5 between the connecting piece and the fixed end of the heating plate are provided between the cable protection sleeve 7 and the connecting piece 6 and are connected by screws or bolts. First install the sealing ring 5 between the connecting piece and the fixed end of the heating plate and the sealing ring 2 between the connecting piece and the protective sleeve into the sealing groove A9 and sealing groove B10 of the connecting piece 6 respectively, and then install the heating wire of the heating plate 1 8 Pass through the central hole 12 of the connecting piece 6, fix the connecting piece 6 and the fixed end of the heating plate 1 together with the fixing bolt 4 between the connecting piece and the fixed end of the heating plate, then arrange the heating wire 8 and put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com