Crack-relief layer sheet positioning pressure-bonding and winding take-up and unwinding device of the coating machine

A technology of positioning device and anti-cracking layer, which is applied in the direction of lamination device, lamination, transportation and packaging, etc. It can solve the problem of many air bubbles on the surface of the composite backplane and the cracked layer material, uneven bullet-proof inserting board surface, Reduce production efficiency and other issues, achieve consistent results, eliminate slippage, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

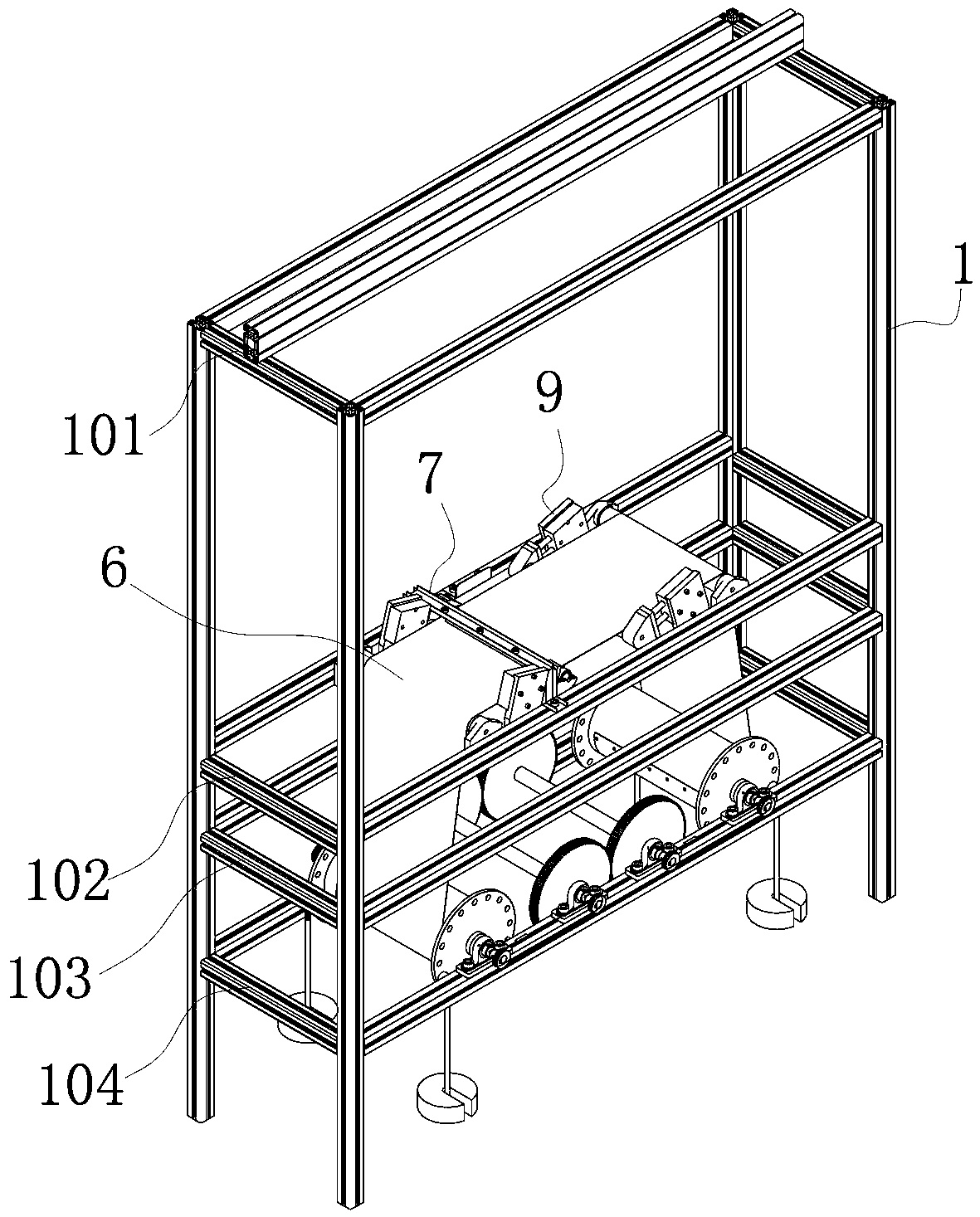

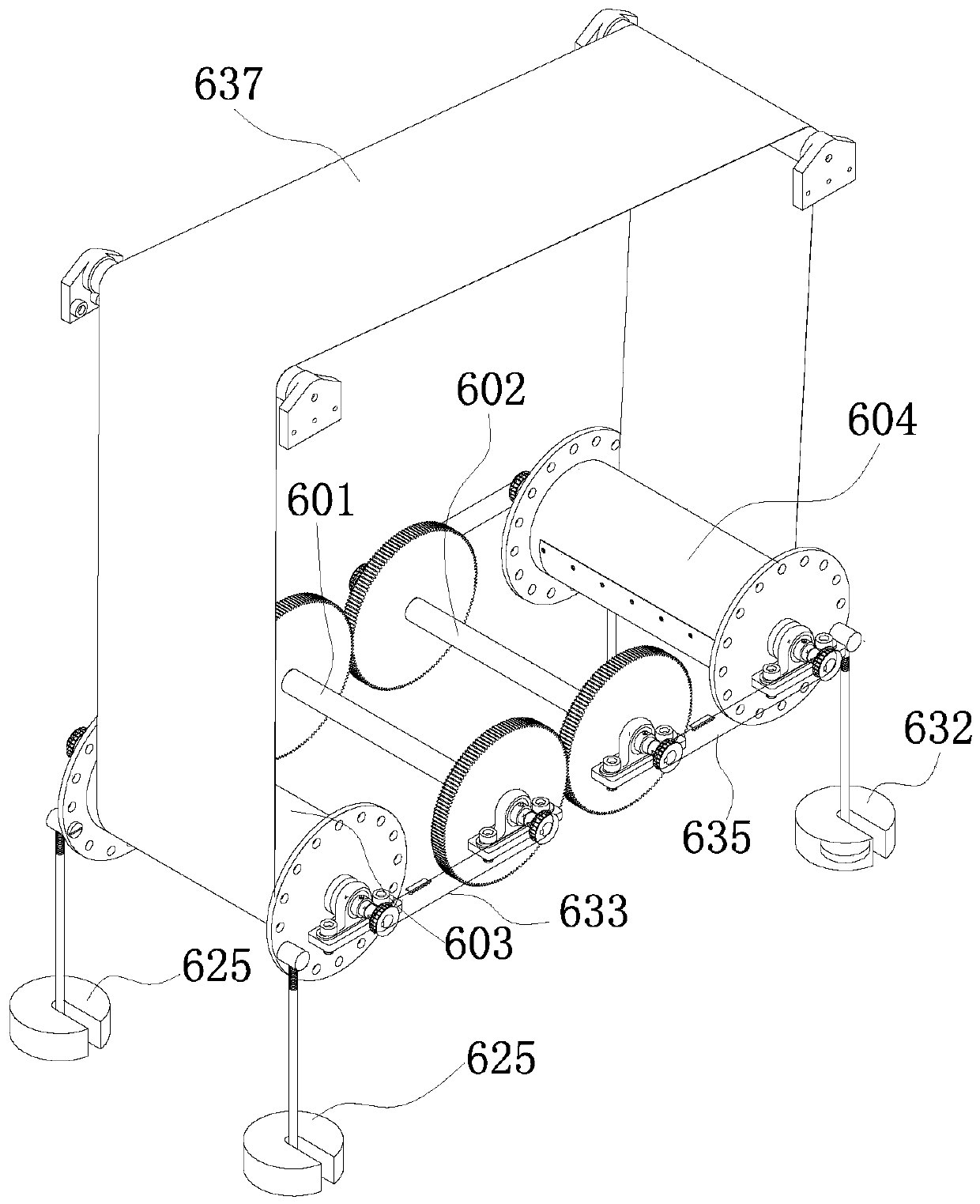

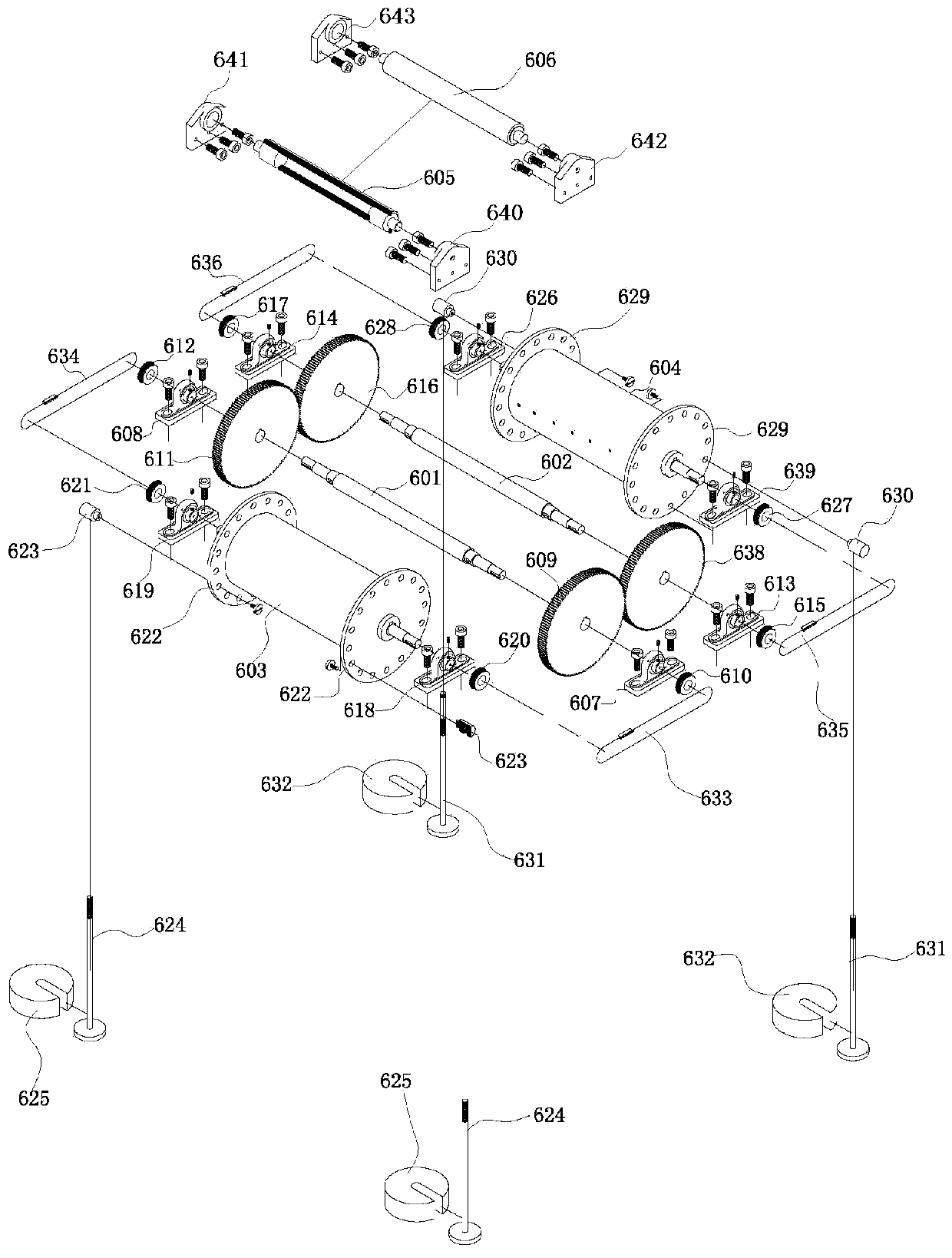

[0030] as attached figure 1 As shown, the present invention includes a frame, a winding belt synchronous tape release and take-up device 6, a crack arresting layer sheet positioning device 7, and a composite backboard pressure-bonding device 9; the frame includes a frame body 1, and the frame body 1 includes a set The upper frame 101 at the top, the middle frame 102 arranged in the middle, the bottom frame 104 arranged at the bottom, and the attached frame 103 arranged between the middle frame 102 and the bottom frame 104; The bottom is fixedly installed on the bottom frame 104, the top of the winding belt synchronous unwinding and taking-up device 6 is fixedly installed on the middle frame 102, and the crack arresting layer sheet positioning device 7 is installed on the middle frame 102 and is located at the winding belt synchronous Above the tape release and take-up device 6 , the composite backboard pressure-bonding device 9 is located inside the top of the winding tape syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com