Polyglutamic acid/sodium alginate adhesive hydrogel and preparation method thereof

A technology of sodium alginate and polyglutamic acid, applied in the field of polyglutamic acid/sodium alginate adhesive hydrogel and its preparation, can solve the problem of weakening material tissue adhesion, surrounding tissue toxicity, and limiting catechu Problems such as the application of phenol modified materials have achieved good application prospects and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

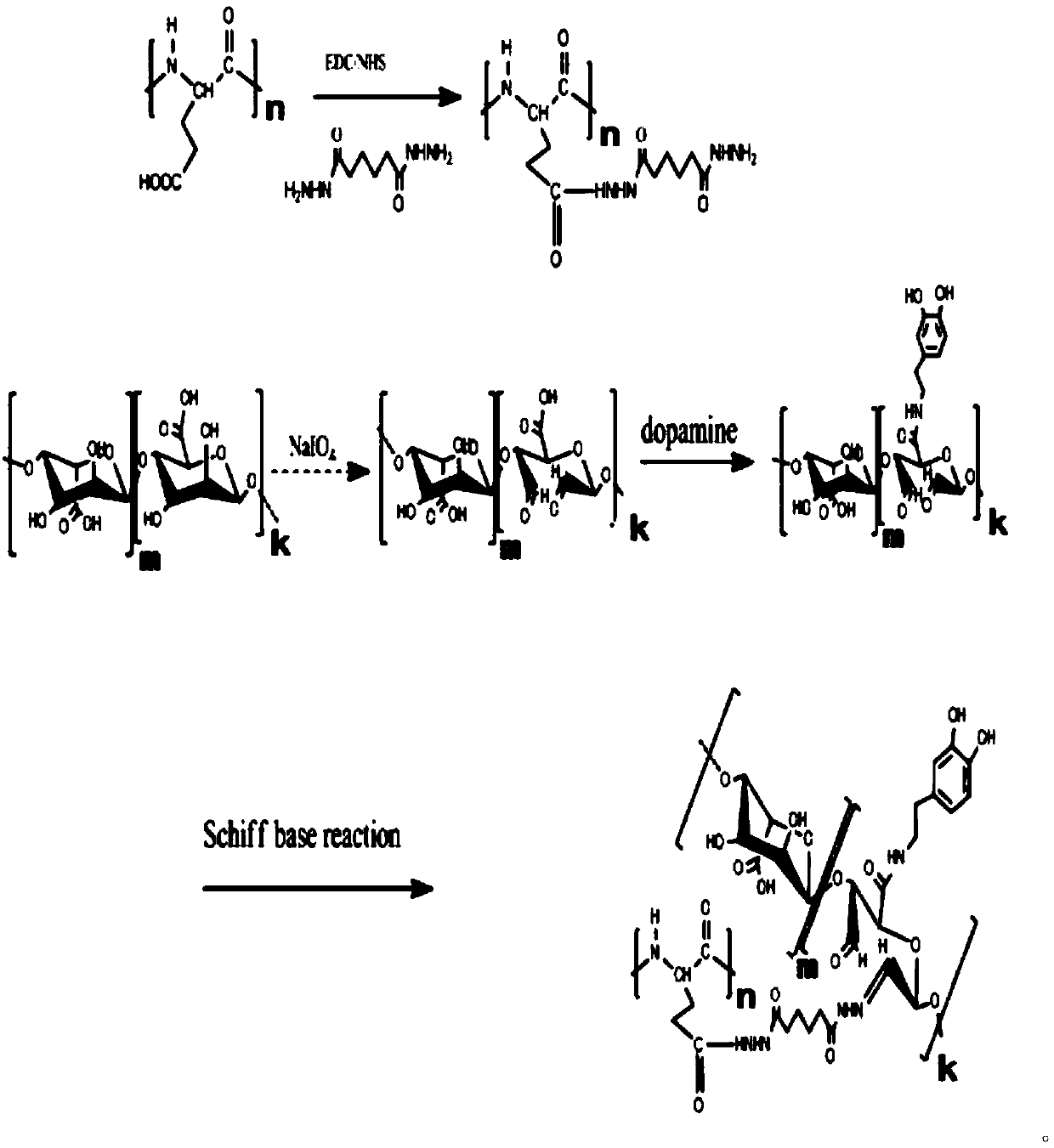

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of oxidized sodium alginate: Weigh 5.0g of sodium alginate into a 250mL beaker, add 150mL of deionized water, stir magnetically and heat to 60°C. After it is completely dissolved, cool to room temperature. Add 1.08 g of sodium periodate which is 0.2 times the amount of sodium alginate structural unit. After reacting for 3 hours under completely dark conditions, add 650ul ethylene glycol to terminate the reaction, stir for 20min and then settle in 2000mL ethanol to obtain a cotton-like solid, then dissolve the obtained solid with 200mL deionized water, and dialyze in deionized water for 3 days, freeze-dried to obtain oxidized sodium alginate with an oxidation degree of 19.4%.

[0022] 2. Preparation of catechol-modified oxidized sodium alginate: Weigh 0.2 g of oxidized sodium alginate prepared in step 1 into a 100 mL beaker, add 40 mL of deionized water, and add appropriate amount of EDC / NHS after fully dissolving the system. Adjust the pH value to about ...

Embodiment 2

[0027] The present embodiment is basically the same as the first embodiment, except that the amount of dopamine hydrochloride in step 2 is reduced from 0.6 g to 0.4 g, and the amount of other reagents and operating conditions remain unchanged. The modification rate of the obtained catechol-modified oxidized sodium alginate was 9%, the elastic modulus of the obtained gel was 1500Pa-1600Pa, and the bonding strength test: the lap shear modulus of cartilage slices was 28KPa.

Embodiment 3

[0029] This example is basically the same as Example 1, except that during the preparation of the poly-L-glutamic acid precursor solution in step 4, no FeCl was added 3 solution. Only 40 mg of ALG-CHO-DP solid was added to 800 uL deionized water to prepare a 5% solution, and the dosage and operating conditions of other reagents remained unchanged. The elastic modulus of the obtained gel was 1500Pa, and the bond strength test: the lap shear modulus of cartilage slices was 28KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap