A kind of pyroelectric flexible composite film and preparation method thereof

A composite membrane and pyroelectric technology, applied in the field of organic ferroelectric polymer materials, can solve the problems of fragile ferroelectric loss of ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Synthesis of lead titanate single crystal nanowires: firstly, 4mmolTi(OC 4 h 9 ) 4 Dissolve in 8ml of absolute ethanol, and then add the solution to 8ml of deionized water for hydrolysis to obtain a milky white suspension. Next, add 20mmolKOH, 5.2mmolPb(NO 3 ) 2 and 0.05g polyvinyl alcohol, and finally add deionized water to adjust the solution to 40ml mixed solution, add the mixed solution into a 50ml reaction kettle, stir at room temperature for 20min, and heat at 200°C for 4h to obtain a white powder, which is titanic acid Lead PX phase precursor. The lead titanate PX phase precursor was annealed at 540°C for 0.5h to make it exhibit ferroelectricity, thereby obtaining lead titanate single crystal nanowires with a perovskite structure with ferroelectric properties, and the obtained lead titanate single crystal nanowires It is a polycrystalline single crystal structure.

[0028] 2. Solution casting film: First, dissolve 0.05556g of lead titanate single crystal...

Embodiment 2

[0031] The specific process steps are the same as in Example 1, except that 0.21428 g of lead titanate single crystal nanowire powder is added in step 2 to obtain a pyroelectric flexible composite film with a composite amount of lead titanate single crystal nanowires of 30 wt%. .

Embodiment 3

[0033] The specific process steps are the same as in Example 1, except that 0.5 g of lead titanate single crystal nanowire powder is added in step 2 to obtain a pyroelectric flexible composite film in which the composite amount of lead titanate single crystal nanowires is 50 wt%. .

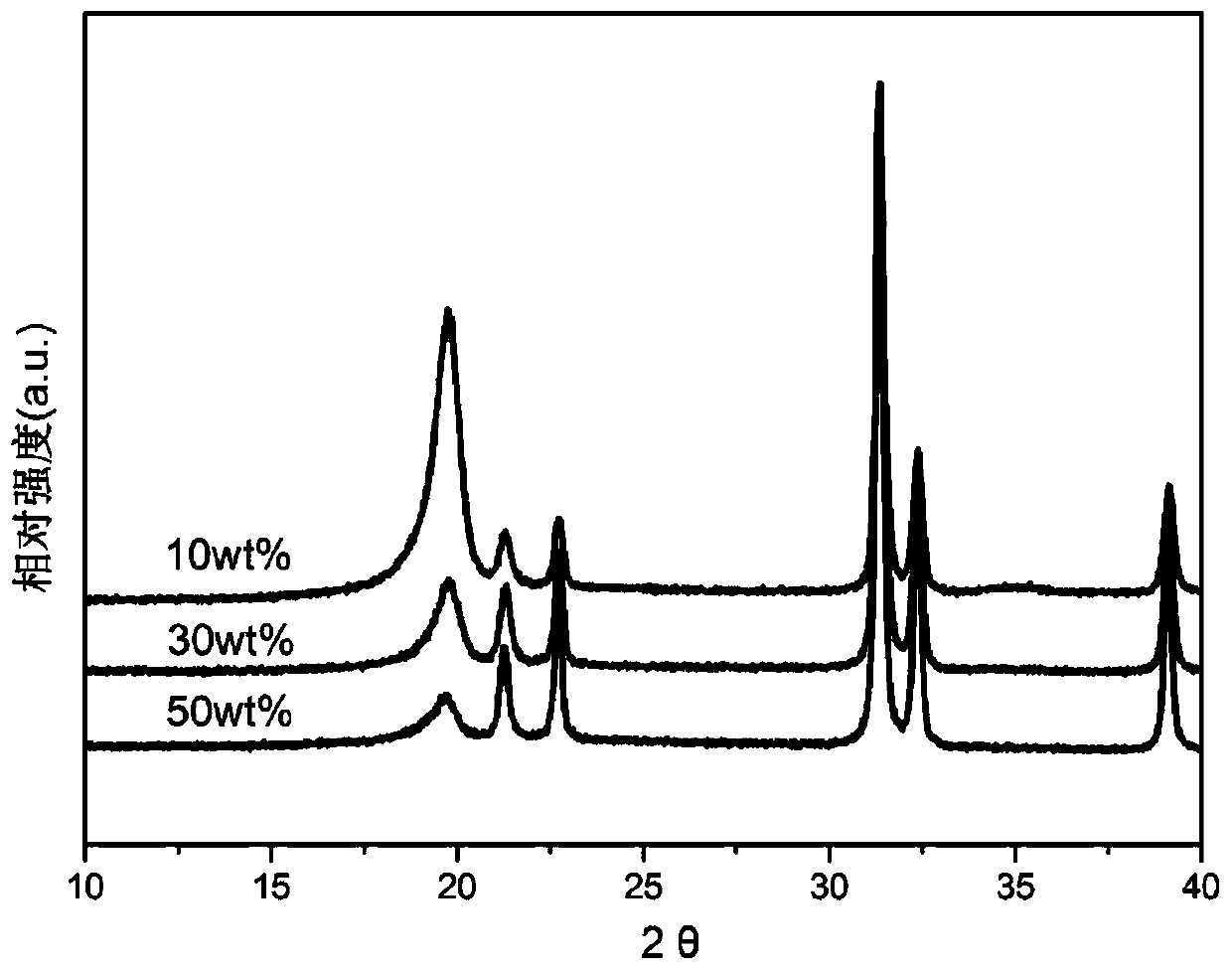

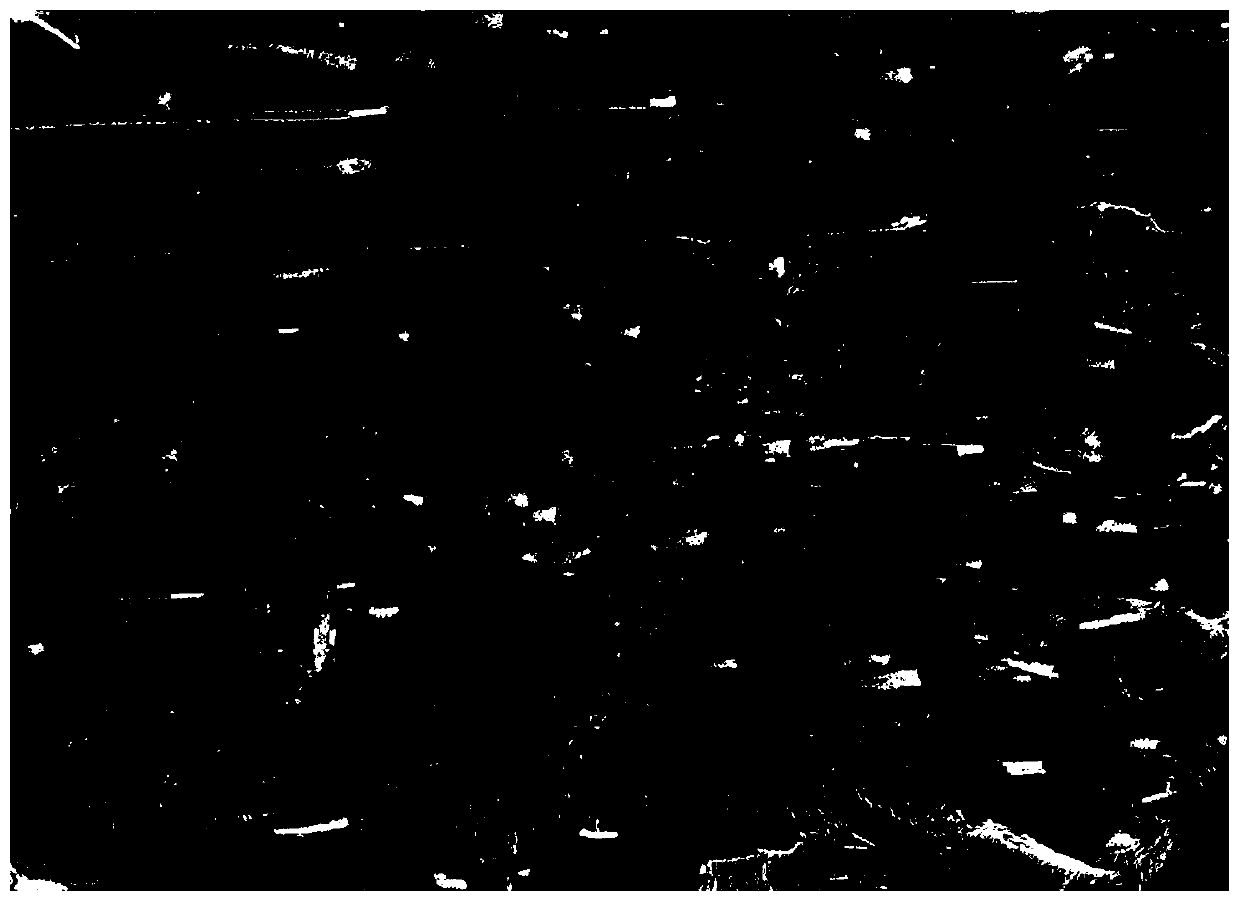

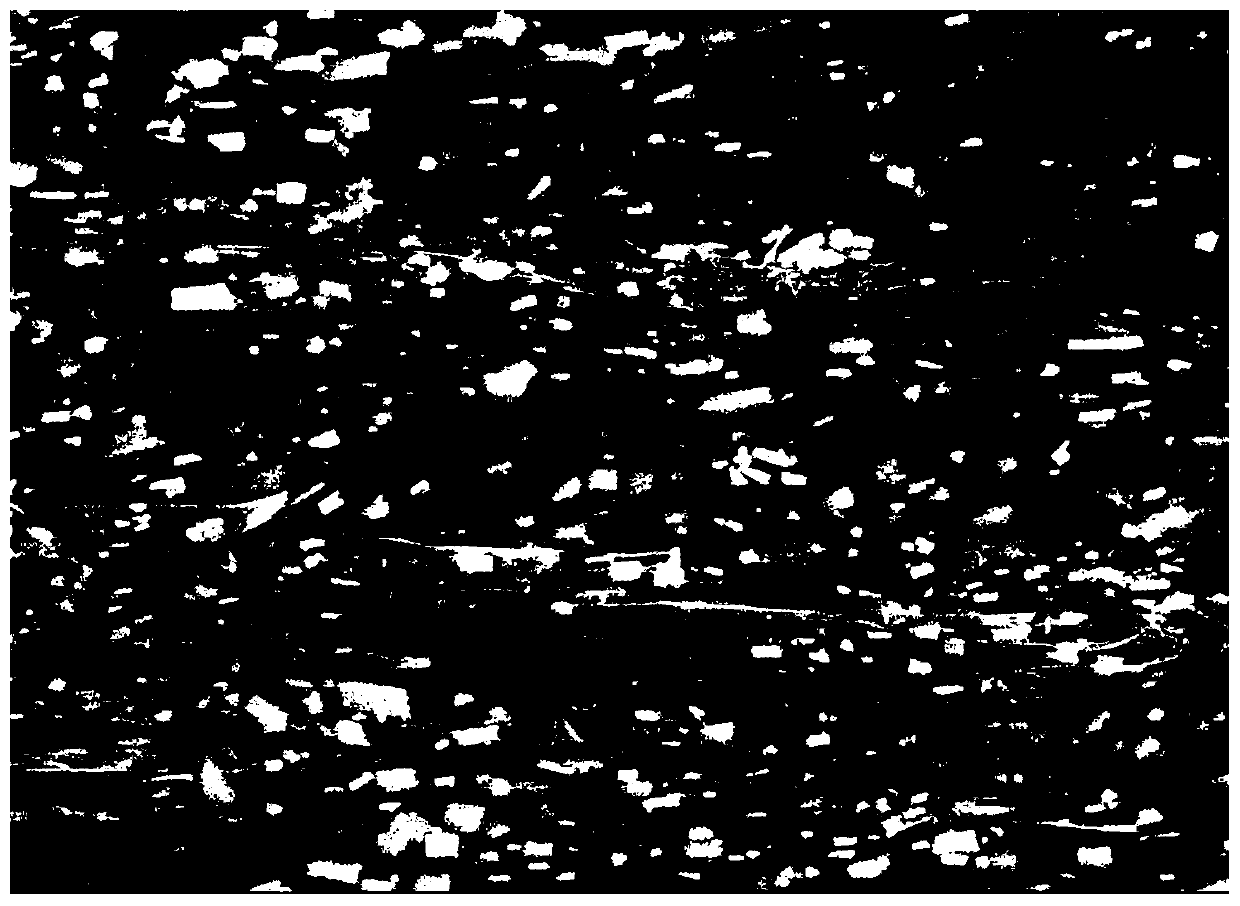

[0034] The thickness of the pyroelectric flexible composite membranes prepared in the above three examples is 100 μm, and its XRD patterns are as follows: figure 1 As shown, it can be seen that both P(VDF-TrFE) and PbTiO with pure β phase 3 Composite of single crystal nanowires. The SEM images of the pyroelectric thin films prepared in the three examples are shown in Figure 2, and they are all dispersed relatively uniformly, but the pyroelectric flexible composite film in Example 3 has a phase separation phenomenon, which has a certain impact on its performance. Multiple tests have determined that the compounding amount of lead titanate single crystal nanowires is 20wt%-40wt%, and the performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com