Bag type low-odor automotive interior polypropylene material and preparation method thereof

A polypropylene material and low-odor technology, which is applied in the field of bag-type low-odor automotive interior polypropylene material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

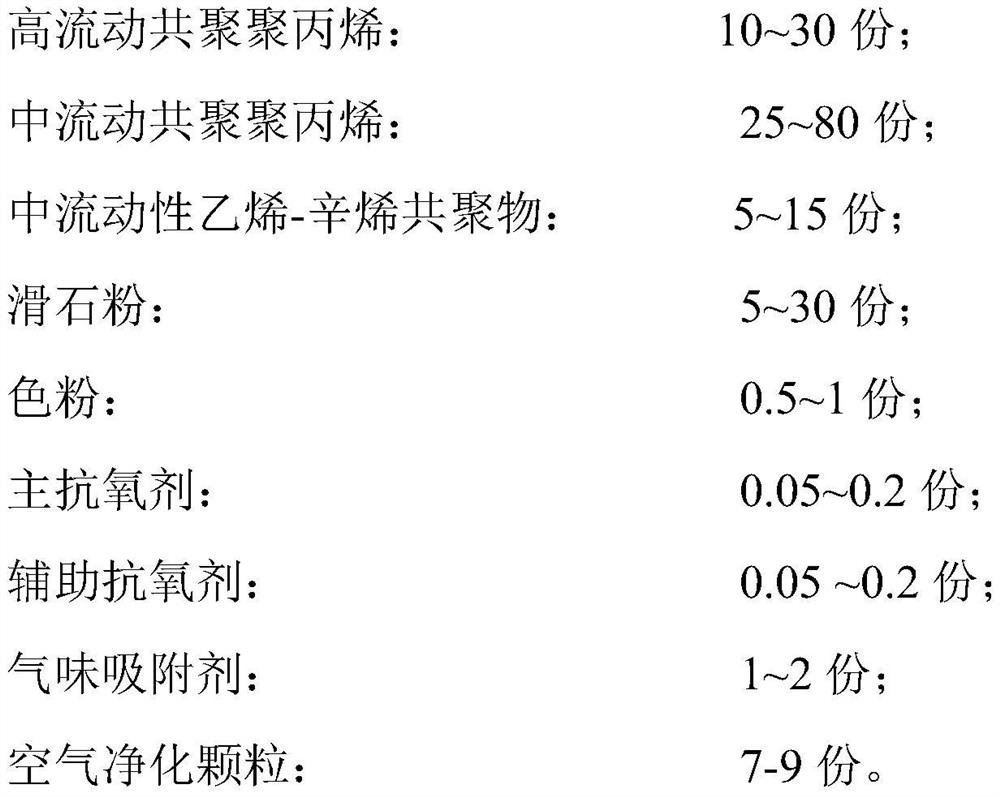

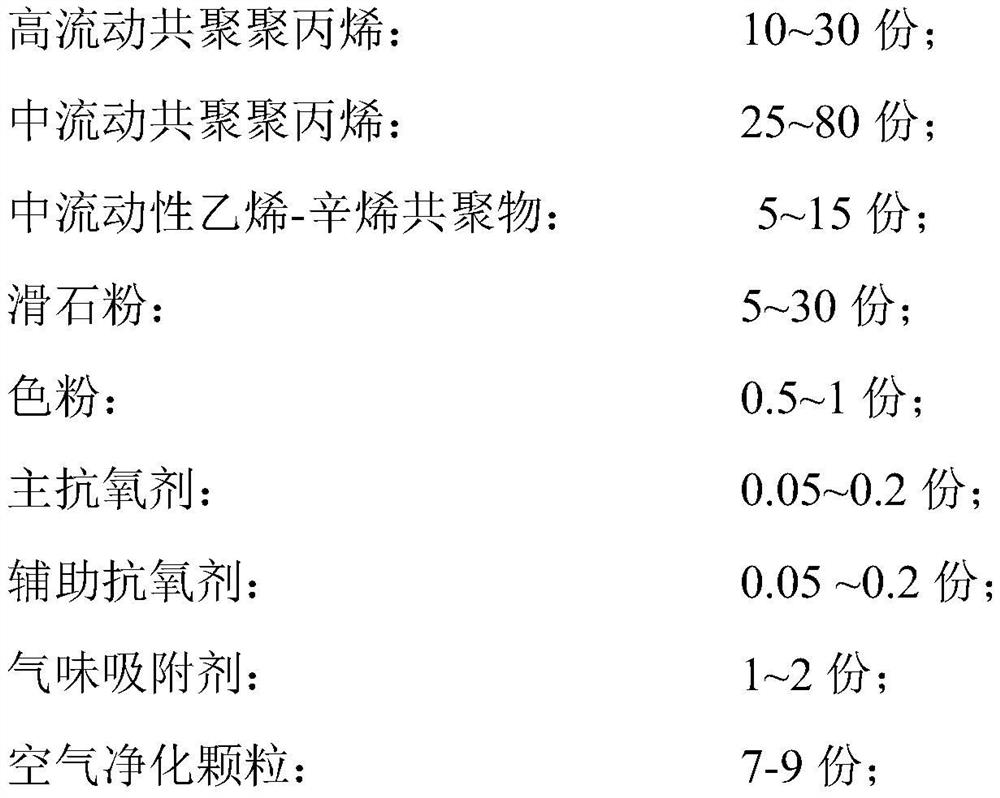

Method used

Image

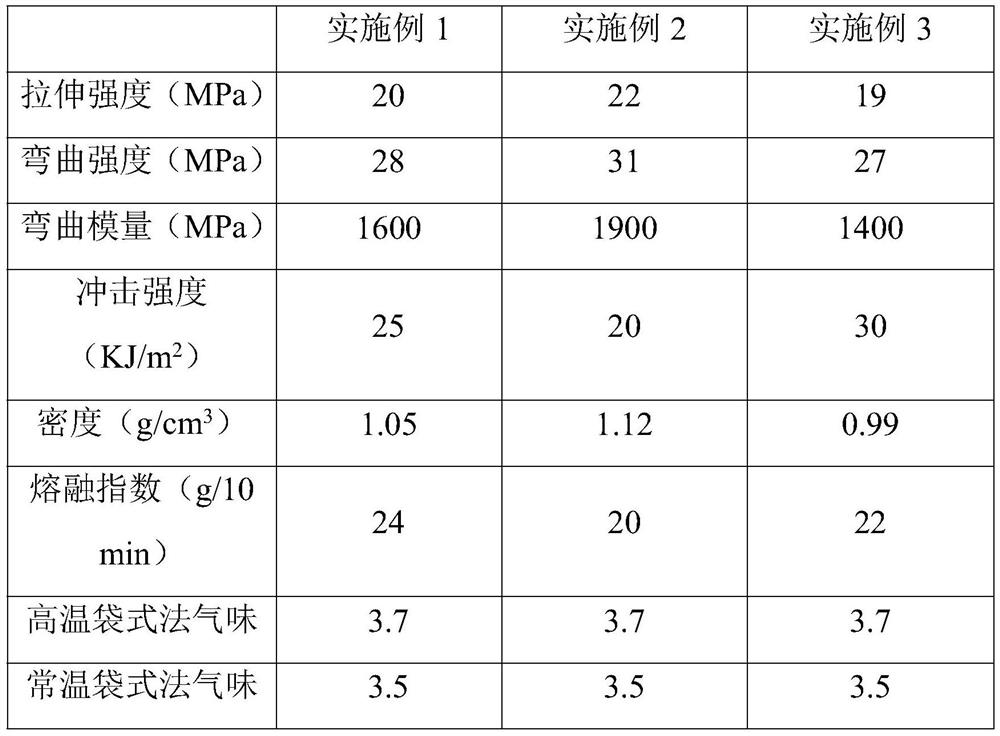

Examples

Embodiment 1

[0037] Preparation of air-purifying particles:

[0038] Glue preparation: according to the mass ratio of 0.1:10:1:100, SiO 2 , Tianqing gum, sodium carboxymethylcellulose and deionized water are mixed to obtain glue;

[0039]Preparation of active substance solution: Mix tourmaline powder, nano-titanium dioxide powder and deionized water at a mass ratio of 7:3:100, ultrasonicate in a water bath for 5 minutes, and the temperature of the water bath is 30°C;

[0040] Preparation of active material precursor solution: under ultrasonic conditions, the active material solution is prepared and added to the glue;

[0041] Preparation of air-purifying particles: the δ-Al 2 o 3 The spherical carrier is placed in the sugar coating machine and sprayed with the above-mentioned active substance precursor solution; the time for each spraying of the active substance precursor solution is 1h, while the carrier is rolling, it is blown with hot air, and after drying, it is sprayed for the seco...

Embodiment 2

[0048] Preparation of air-purifying particles:

[0049] Glue preparation: according to the mass ratio of 10:3:0.3:100, SiO 2 , Tianqing gum, sodium carboxymethylcellulose and deionized water are mixed to obtain glue;

[0050] Preparation of active substance solution: Mix tourmaline powder, nano-titanium dioxide powder and deionized water at a mass ratio of 9:4:100, ultrasonicate in a water bath for 5 minutes, and the temperature of the water bath is 35°C;

[0051] Preparation of active material precursor solution: under ultrasonic conditions, the active material solution is prepared and added to the glue;

[0052] Preparation of air-purifying particles: α-Al 2 o 3 The spherical carrier is placed in the sugar-coating machine and sprayed with the above-mentioned active substance precursor solution; the time for each spraying of the active substance precursor solution is 2 hours, and hot air is blown to it while the carrier is rolling, and the second spray is carried out after...

Embodiment 3

[0059] Glue preparation: by mass, 7:2:1:100, SiO 2 , Tianqing gum, sodium carboxymethylcellulose and deionized water are mixed to obtain glue;

[0060] Preparation of active substance solution: Mix tourmaline powder, nano-titanium dioxide powder and deionized water in a mass ratio of 8:3:100, ultrasonically in a water bath for 10 minutes, and the temperature of the water bath is 40°C;

[0061] Preparation of active material precursor solution: under ultrasonic conditions, the active material solution is prepared and added to the glue;

[0062] Preparation of air-purifying particles: the δ-Al 2 o 3 The spherical carrier is placed in the sugar-coating machine and sprayed with the above-mentioned active substance precursor solution; the time for each spraying of the active substance precursor solution is 2 hours, and hot air is blown to it while the carrier is rolling, and the second spray is carried out after drying, and the number of sprays is 4 times. The active material pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com