Preparation method of polyvinylidene fluoride micrometer bulb tube

A technology of polyvinylidene fluoride and micron bulbs, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high technical difficulty, high equipment requirements, high cost, etc., and achieve cheap and easy-to-obtain raw materials and easy operation Ease of operation, good high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of a polyvinylidene fluoride micron tube, comprising the following steps:

[0016] 1) First, heat the mixture of 70% polyvinylidene fluoride (mass percentage) and polybutylacrylate (mass percentage) 30% to 195 ° C for 10 minutes to eliminate the heat history, and then the mixed melt is rapidly heated at a rate of 50 ° C / min Cool down to 170°C;

[0017] 2) Utilize a polymethylsiloxane plate to apply 10 4 Pa pressure applies shear stress to the melt, and it stands at 170°C for 15 days to crystallize polyvinylidene fluoride;

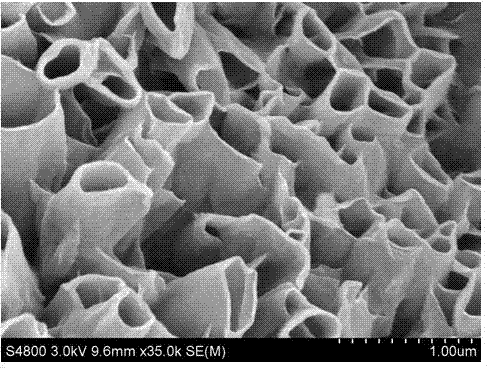

[0018] 3) Soak the fully crystallized blend in chloroform solution to etch away the polyacrylate component. After soaking for three days, only polyvinylidene fluoride crystals remain in the blend. Take out the polyvinylidene fluoride crystals and dry them, and scan them with a scanning electron microscope. The test can obtain polyvinylidene fluoride micron tubes.

[0019] The average diameter of the micron tube is 0.5 μm.

Embodiment 2

[0021] A preparation method of a polyvinylidene fluoride micron tube, comprising the following steps:

[0022] 1) First, heat the mixture of 50% polyvinylidene fluoride (mass percentage) and polybutylacrylate (mass percentage) 50% to 200 ° C for 10 minutes to eliminate the heat history, and then rapidly mix the melt at a rate of 50 ° C / min Cool down to 170°C;

[0023] 2) Utilize a polymethylsiloxane plate to apply 10 5 Pa pressure applies shear stress to the melt, and it stands at 170°C for 15 days to crystallize polyvinylidene fluoride;

[0024] 3) Soak the fully crystallized blend in chloroform solution to etch away the polyacrylate component. After soaking for three days, only polyvinylidene fluoride crystals remain in the blend. Take out the polyvinylidene fluoride crystals and dry them, and scan them with a scanning electron microscope. Detection can obtain polyvinylidene fluoride microtubes.

[0025] The average diameter of the microsphere tube is 1 μm.

Embodiment 3

[0027] A preparation method of a polyvinylidene fluoride micron tube, comprising the following steps:

[0028] 1) First, heat the mixture of 30% polyvinylidene fluoride (mass percentage) and polybutylacrylate (mass percentage) 70% to 205 ° C for 10 minutes to eliminate the heat history, and then rapidly mix the melt at a rate of 50 ° C / min Cool down to 170°C;

[0029] 2) Utilize a polymethylsiloxane plate to apply 10 5 Pa pressure applies shear stress to the melt, and it stands at 170°C for 15 days to crystallize polyvinylidene fluoride;

[0030] 3) Soak the fully crystallized blend in chloroform solution to etch away the polyacrylate component. After soaking for three days, only polyvinylidene fluoride crystals remain in the blend. Take out the polyvinylidene fluoride crystals and dry them, and scan them with a scanning electron microscope. The test can obtain polyvinylidene fluoride micron tubes.

[0031] The average diameter of the micron tube is 2.5 μm.

[0032] see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com