Anti-climbing device for electric iron tower

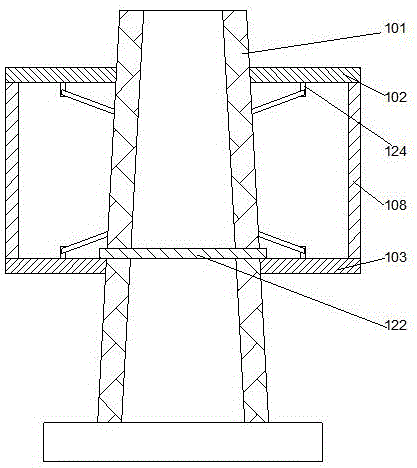

A power tower and anti-climbing technology is applied in the field of anti-climbing devices for power iron towers, which can solve the problems of inconvenient maintenance work, obstacles in the climbing process, movement, etc., and achieve the effect of convenient maintenance and good anti-climbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

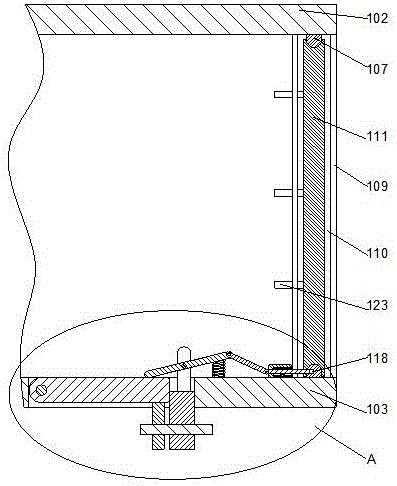

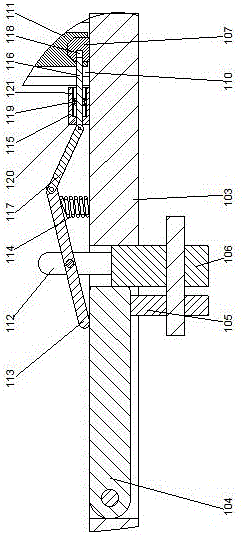

[0028] In this embodiment, in order to make the slide plate relatively fixed on the slide rail, preferably, the slide rail 107 is provided with a counterbore 118 corresponding to the position of the through hole, and the end of the positioning pin 116 It can be plugged into the inner side of the counterbore 118, and when the pull bar is in a horizontal state, the pull bar can push the locating pin to be inserted into the locating hole and the inside of the counterbore, so that the slide plate can be fixed on the slide rail.

Embodiment 2

[0030] In this embodiment, in order to keep the locating pin stable in the through hole, preferably, a disc 119 is provided in the middle of the locating pin 116, and a convex plate is provided at the end of the through hole close to the pull rod 117. The outer diameter of the disc 119 is greater than the inner diameter of the flange 120 . By arranging the flange and the disc structure, the positioning pin can be prevented from coming out of the through hole on the baffle.

[0031] Further preferably, in this embodiment, in order to enable the positioning pin to move along the fixed track, a positioning groove 121 is provided on the inner wall of the through hole, and the length direction of the positioning groove 121 is parallel to the through hole In the lengthwise direction, a slider capable of sliding along the positioning groove 121 is provided on the outer edge of the disc 119 . By setting the positioning groove structure, the positioning pin can move along the through ...

Embodiment 3

[0033] In this embodiment, in order to improve the stability of the slide plate and enable the slide plate to move along a fixed track, preferably, a slide groove is provided on the end surface of the card slot 110 close to the tower body 101. A cylinder 123 capable of sliding along the chute is provided on the sliding plate 111 . In the present invention, the chute is arranged along the circumferential direction of the cover body, and when the slide plate is slid along the slide rail, the cylinder on the slide plate can move along the chute, which can improve the stability of the slide plate. A groove is arranged on the cylinder, so that the side wall of the chute is clamped on the inside of the groove, so that the cylinder cannot be moved out of the chute. The present invention adopts the slide rails on the upper support plate and the lower support plate so that the slide plate does not move in the vertical direction during the relative movement process, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com