Compression and heat resistant gear-connected bar type sealing door

A technology of gear connecting rod and sealing door, applied in the field of sealing door, can solve the problems of poor adaptability, poor reliability, single function, etc., and achieve the effects of simple structure, pressure resistance, heat resistance, safety and reliability, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

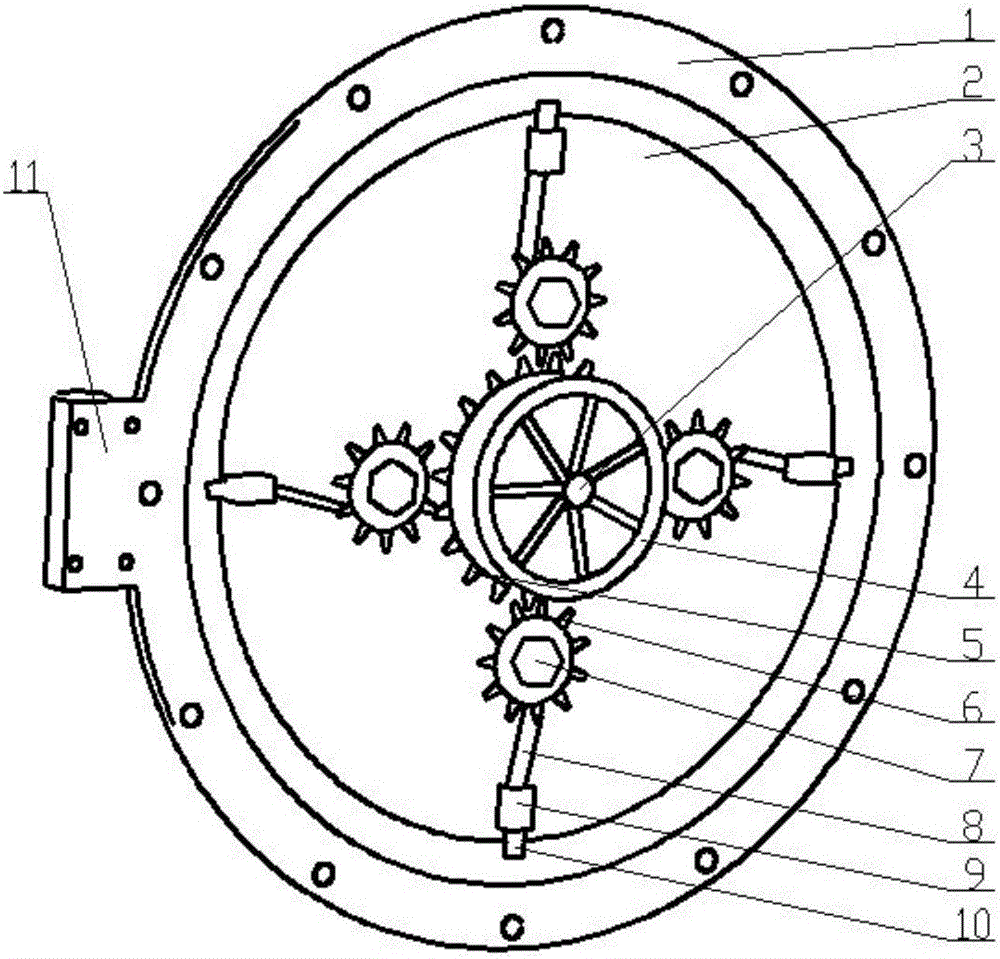

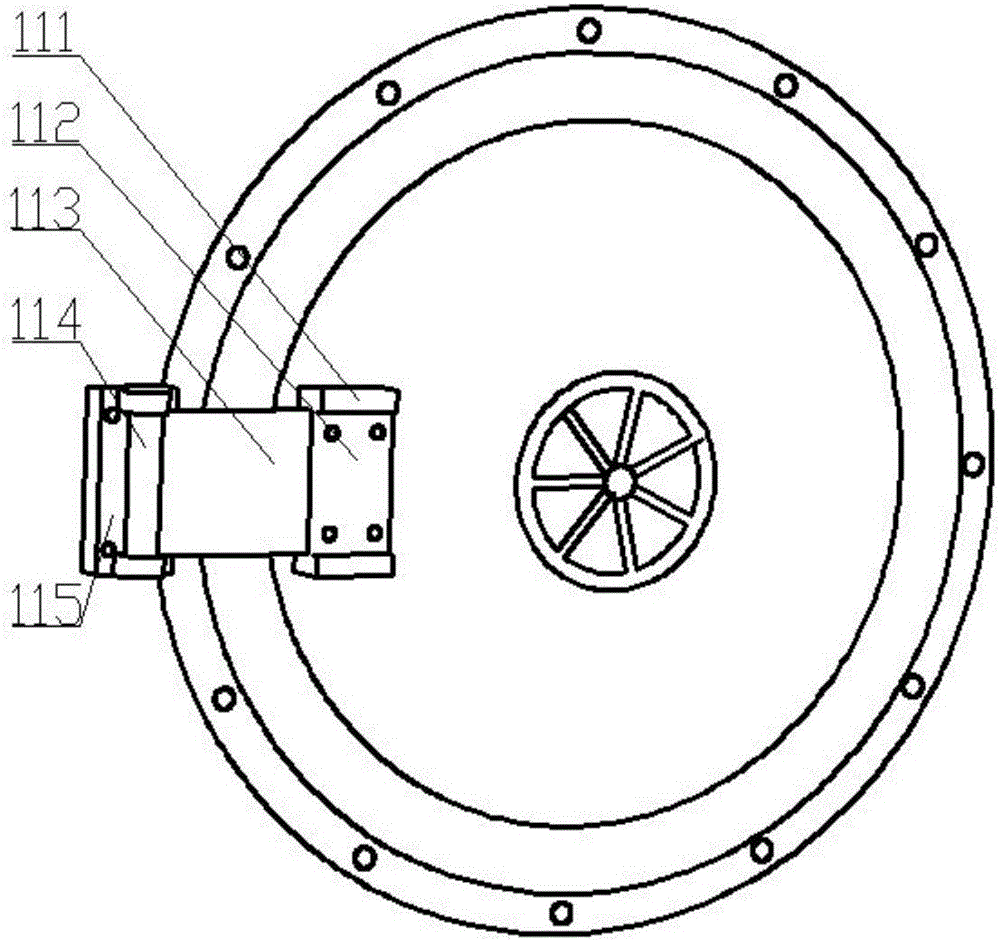

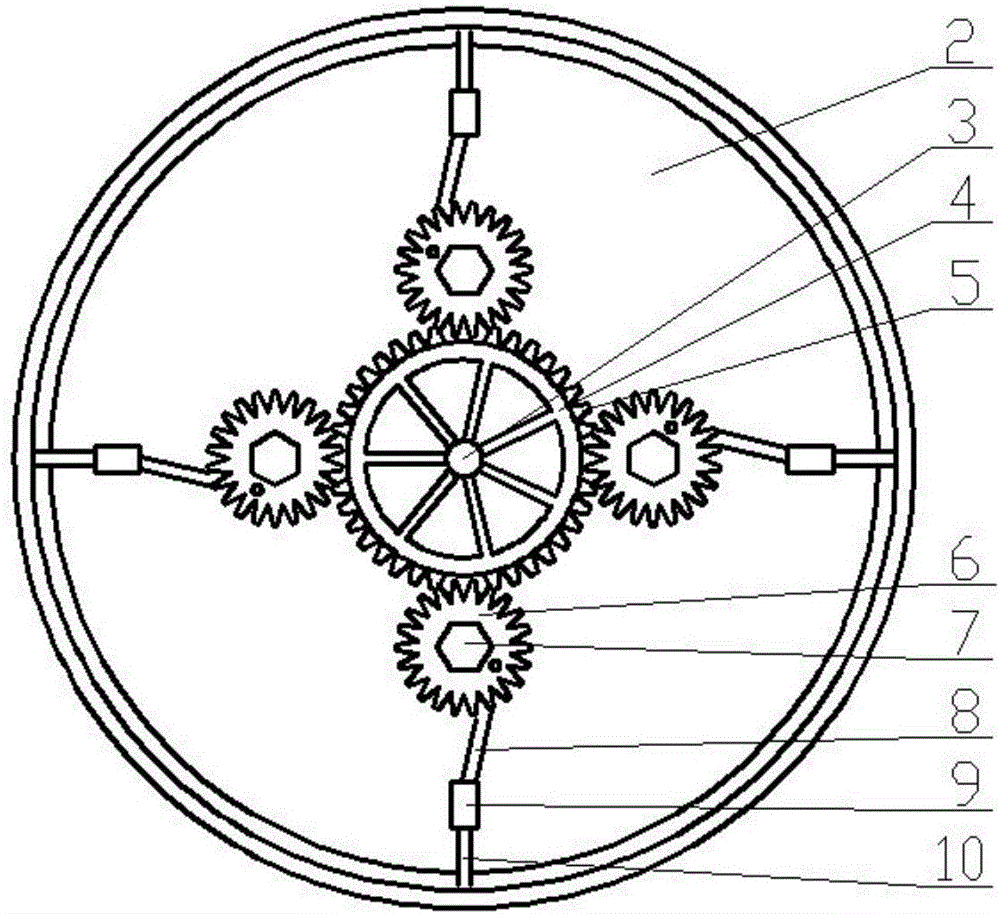

[0018] Such as figure 1 , 2 , 3 and 4, a pressure-resistant and heat-resistant gear-link type airtight door, including: door frame 1, door body 2, hand wheel shaft 3, hand wheel 4, driving gear 5, driven gear 6, hexagonal pressure cap 7. Connecting rod I8, guide groove 9, connecting rod II10, hinge 11; the door frame 1 is a ring-shaped structure with a proper amount of circular holes on the ring, which are connected to the cabinet body to be sealed by bolts, There is a small chamfer on the inner side of the ring, which facilitates the entry of the flat end of the connecting rod II10 to complete the locking of the airtight door; There is a notch, and a high-temperature-resistant rubber strip is installed in the notch to ensure the airtightness of the whole device and prevent the intrusion of toxic and harmful gases; the handwheel shaft 3 is installed on the middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com