Engine block of an internal combustion engine

A technology of engine block and internal combustion engine, applied in the direction of machine/engine, engine element, cylinder, etc., can solve the problem of difficult design of cylindrical area, and achieve the effect of small cutting work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

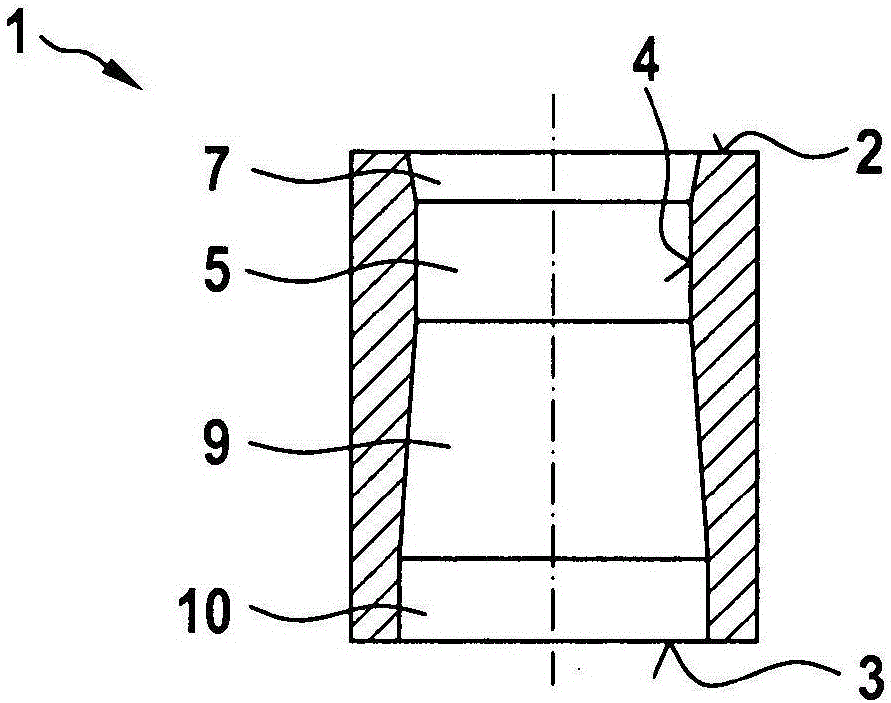

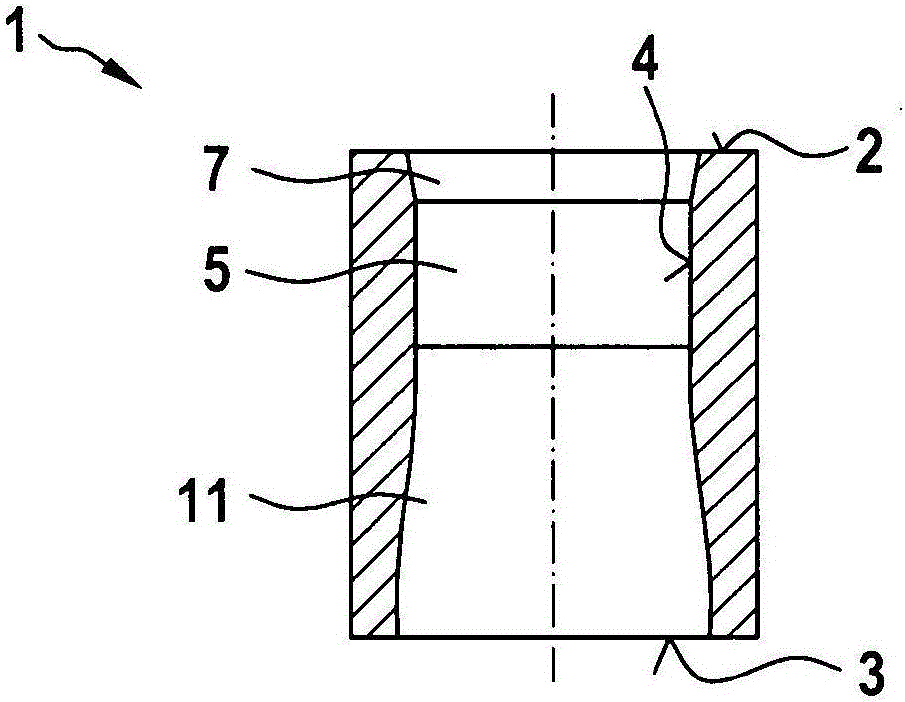

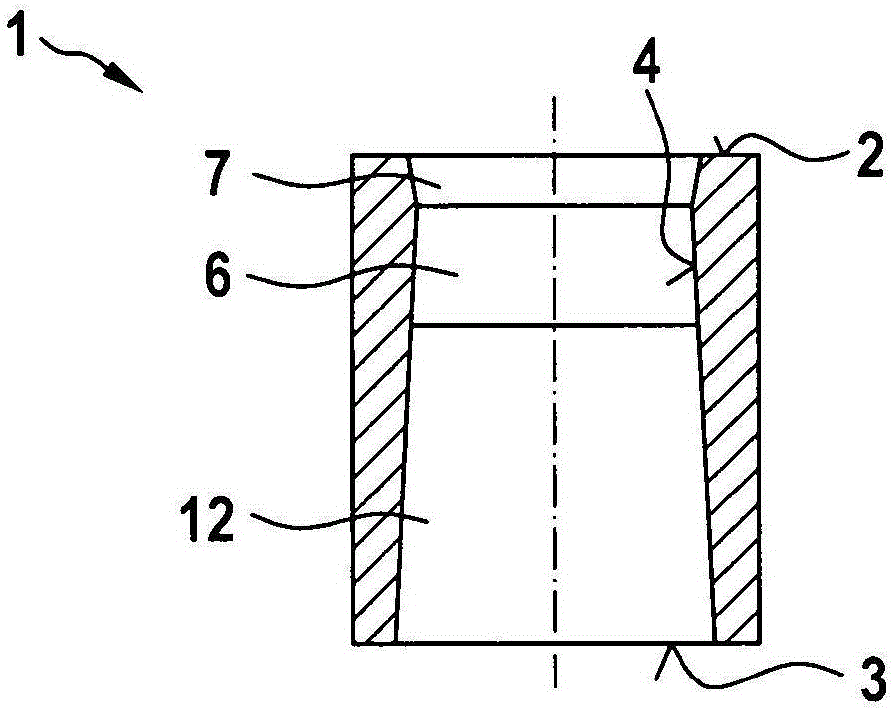

[0034] figure 1 The engine block 1 according to the first exemplary embodiment is shown schematically. The engine block 1 has cylinders, which are represented by cylinder bores 4 . The cylinder bore 4 extends between the upper end 2 and the lower end 3 . In this case, the upper end 2 corresponds to that end onto which the cylinder head can be placed. The lower end 3 corresponds to that end onto which the crankcase can be placed. A piston can be arranged within the cylinder bore 4 , which can move up and down within the cylinder bore 4 in order to operate the internal combustion engine.

[0035] The cylinder bore 4 has a larger diameter than the smallest diameter in the region between the lower end 3 and a boundary which is at most 70%, preferably at most 60% of the distance between the upper end 2 and the lower end 3 from the upper end 2 %, particularly preferably up to 50%. Furthermore, it is provided that the diameter in this region increases at least in places towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com