Fan assembly integrating with water-cooling system

A technology of water cooling system and condensing components, which is applied to the components of pumping devices for elastic fluids, pump components, mechanical equipment, etc., can solve the problems of affecting noise level and temperature, large vibration, no sound insulation, etc. Amplitude, the effect of reducing noise level, reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

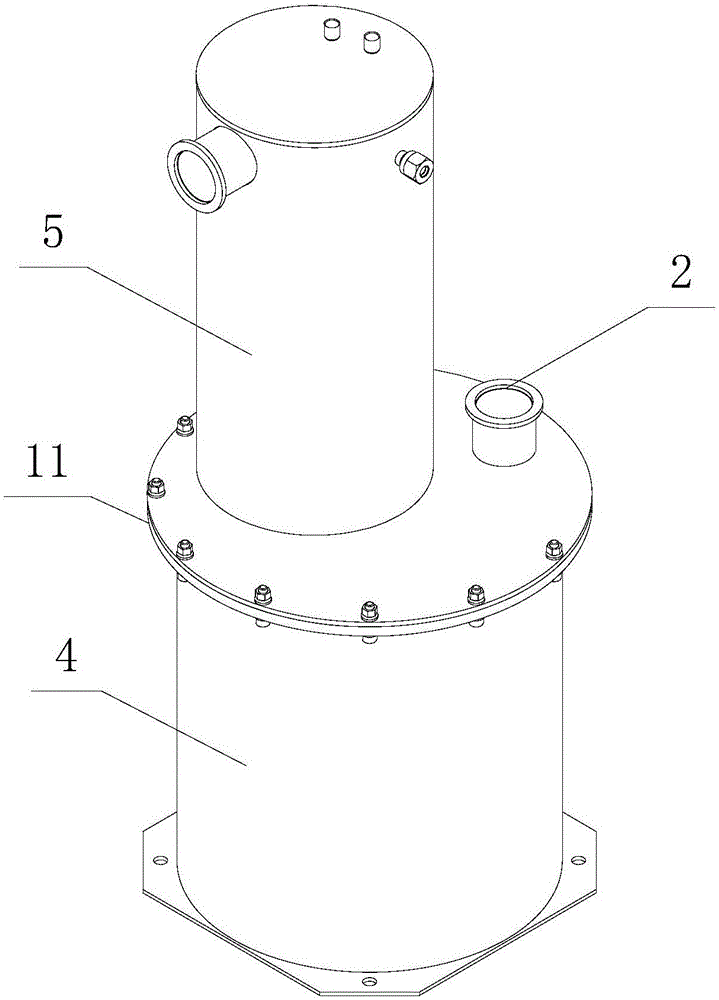

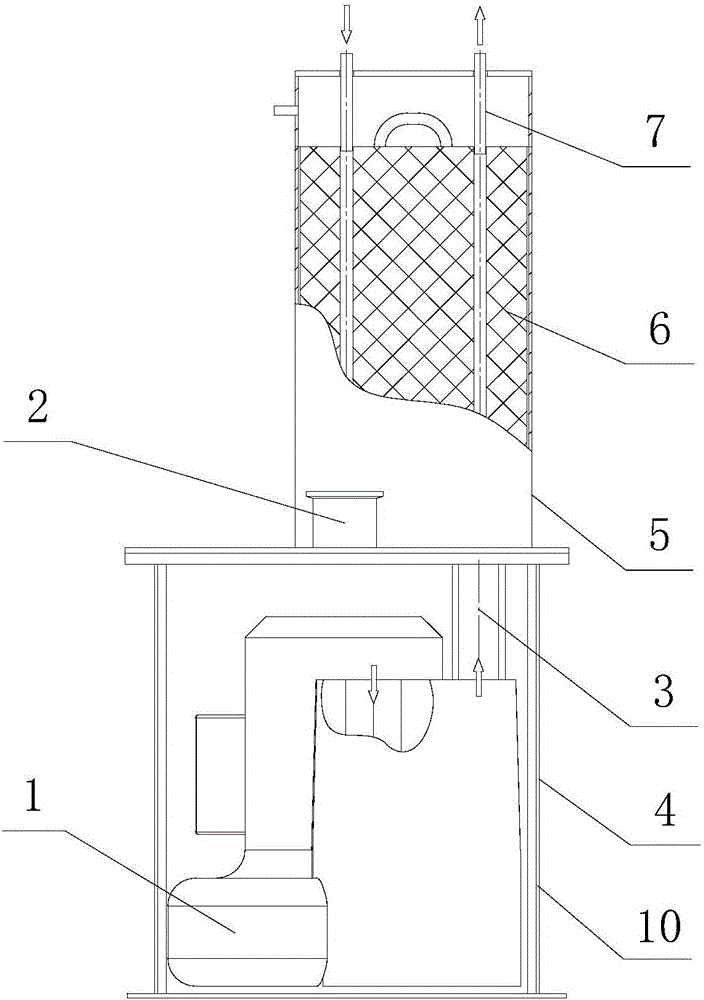

[0015] Example: see figure 1 , figure 2 and image 3 , a fan assembly for an integrated water cooling system, including an air supply assembly and a condensing assembly fixedly connected thereto, the air supply assembly includes an air supply sealed casing 4 and a fan 1 inside, the two ends of the fan 1 are respectively an air inlet 2 and a Air outlet 3, the air outlet 3 is connected to the condenser 6 assembly; the condensing assembly includes the condenser shell 5 and its internal condenser 6 and cooling water pipeline 7, and the cooling water pipeline 7 is inserted in the condenser 6 reciprocating setting;

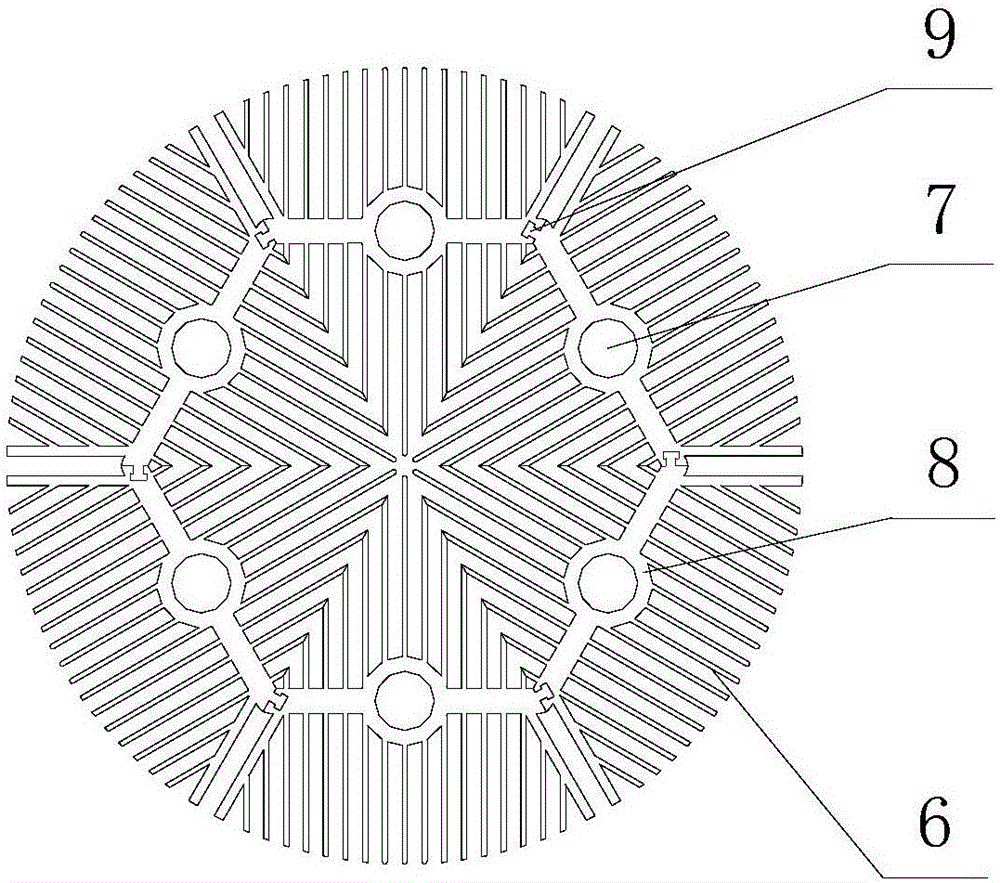

[0016] The condenser 6 is a cylindrical structure, and is composed of six sectors with the same size in section, and a vertical through hole 8 is provided in the middle of each part for the cooling water pipeline 7 to pass through, and two adjacent Sectors are fixedly connected to each other by sliding grooves 9 in the vertical direction.

[0017] As a preference, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com