Automobile transmission exhaust device

A technology for automotive transmissions and exhaust devices, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve problems such as corrosion, transmission function failure, and high energy consumption of the transmission, so as to achieve good anti-pollution effect and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

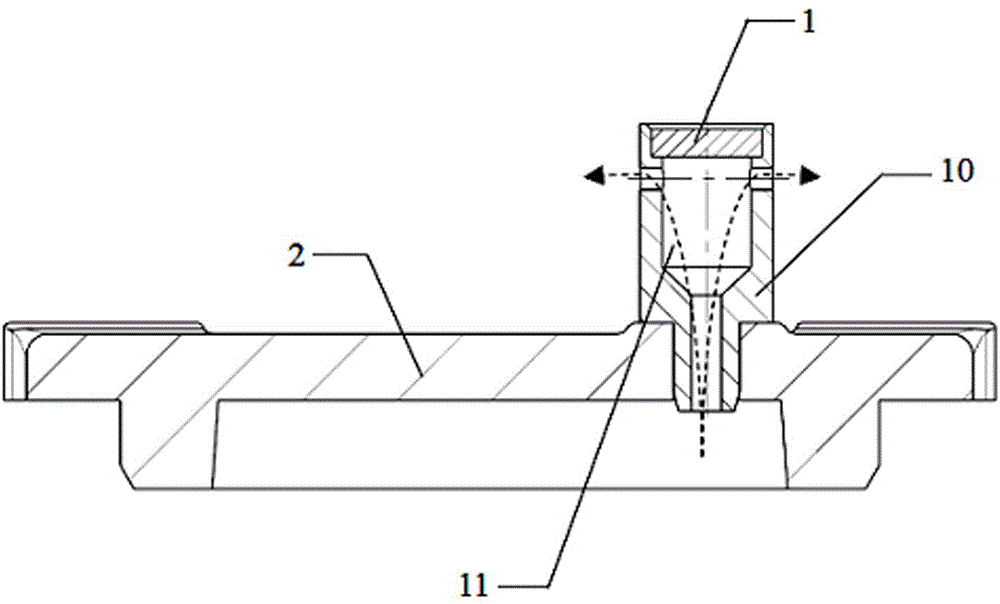

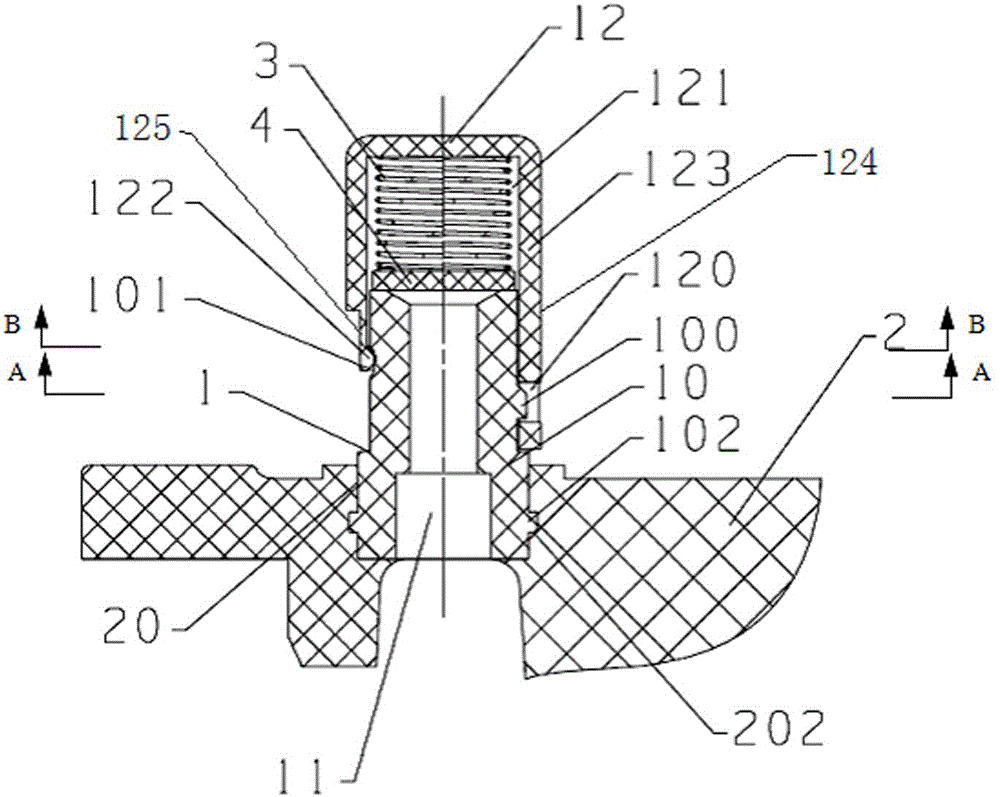

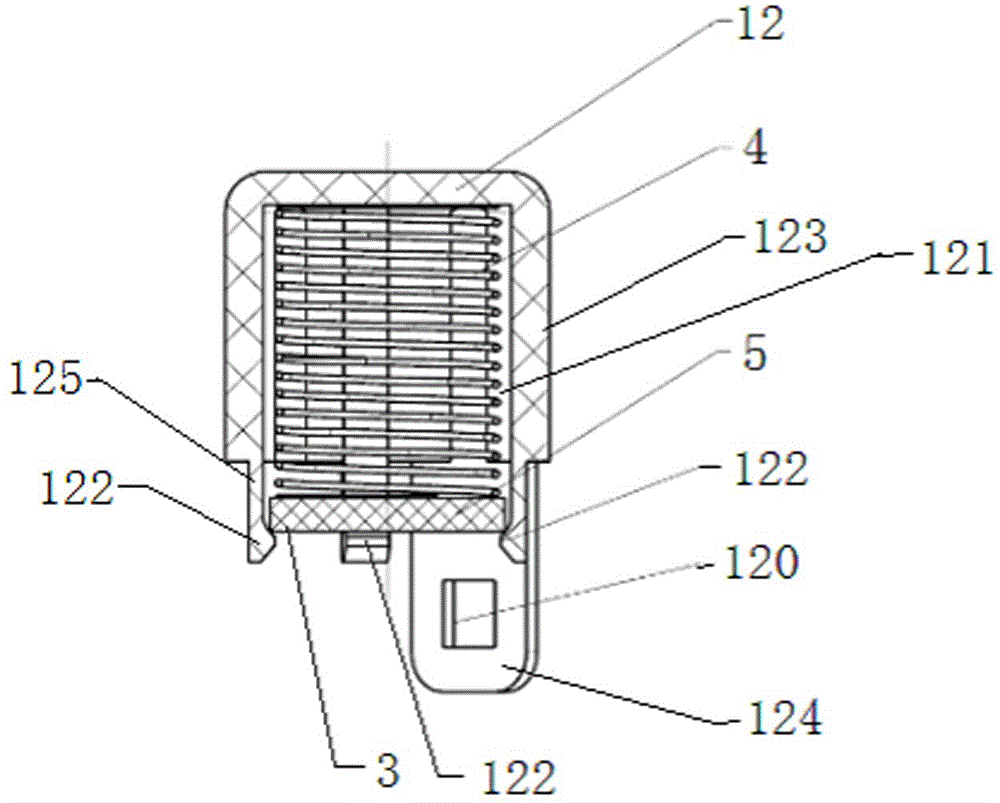

[0024] see Figures 2 to 5 , the automobile transmission exhaust device of the present invention, comprises exhaust plug 1, and described exhaust plug 1 comprises the exhaust plug body 10 that lower end is connected with transmission box 2 and is positioned at the outside of transmission box body 2, and by exhaust plug body 10 The lower end of the lower end communicates with the inside of the transmission case 2. The exhaust passage 11. Depend on Figures 2 to 5It can be seen that the present invention also includes the exhaust plug cover 12 made of elastic material, the spring 3 and the barrier piece 4, and the snap-in structure 120, 100. The exhaust plug cover 12 includes an exhaust plug cover with a lower end opening The exhaust plug cover 123 of the cavity 121, the exhaust channel 11 in the exhaust plug body 10 of the exhaust plug 1 run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com