Annular bin system of large submerged arc furnace

A submerged arc furnace and silo technology, applied to furnaces, preheating costs, furnace components, etc., can solve problems such as uniform heating of unfavorable raw materials, unfavorable electrode layout, inaccurate raw material consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

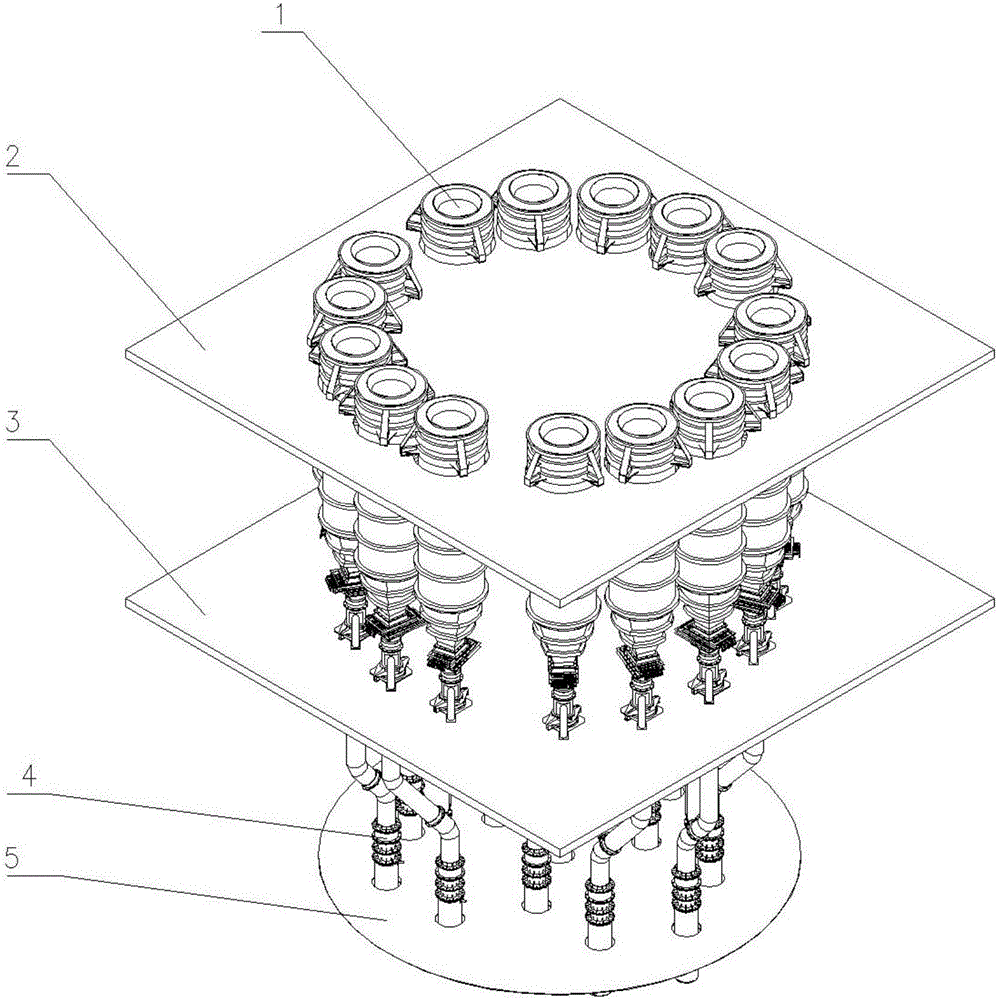

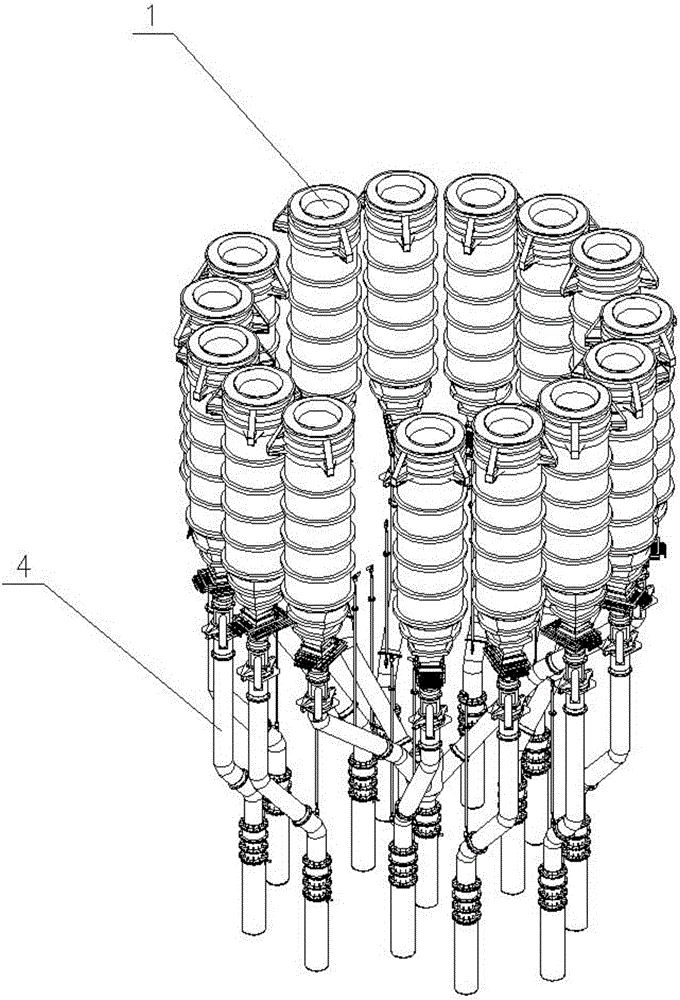

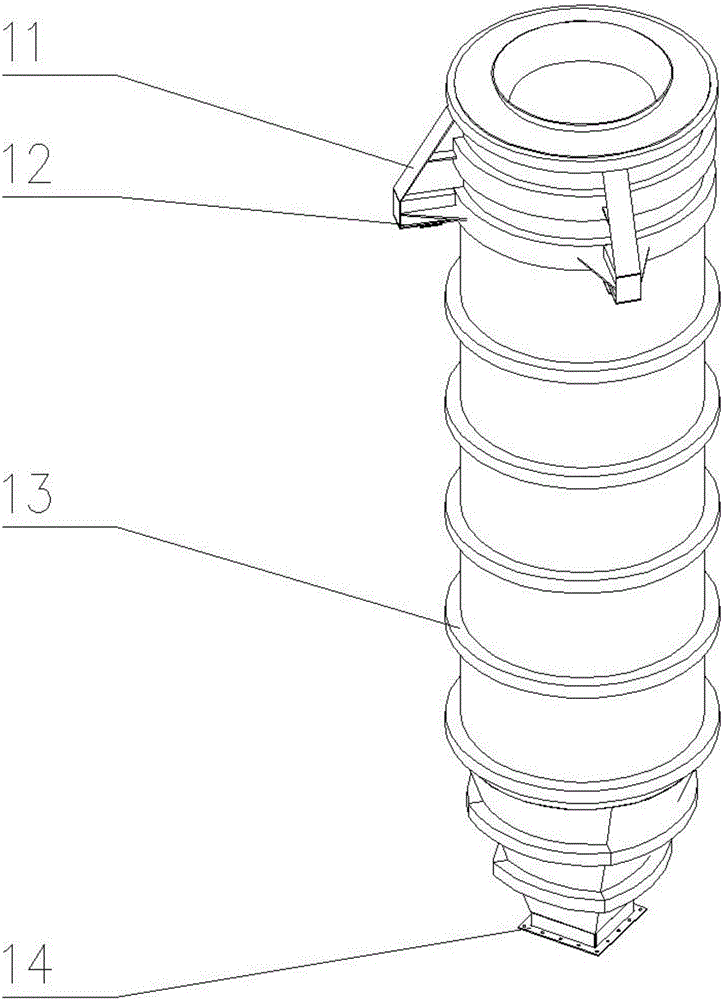

[0029] Such as figure 1 with figure 2 As shown, a large submerged arc furnace annular feed bin 1 system includes a vertical feed bin 1 (the feed bin 1 is provided with circular reinforcing ribs 13 arranged in the axial direction), the first layer platform 2, the second The two-layer platform 3 and the material pipe 4 corresponding to the material bin 1 one-to-one, all the material bins 1 are distributed around the axis of the system and divided into three groups (5 groups in this embodiment, but can be adjusted according to actual needs) ), the intervals between groups are equal (larger intervals), and the intervals between feed bins 1 of the same group are equal (smaller intervals). Pass through the first platform 2 and be supported on the first platform 2 by the silo support seat 11. The top of the material pipe 4 is connected to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com