Operating temperature optimization method and design method for gravity loop heat pipe system

A loop heat pipe, operating temperature technology, used in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as inability to express relationships, inability to obtain optimal results, and inability to achieve working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present invention. Unless otherwise specified, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

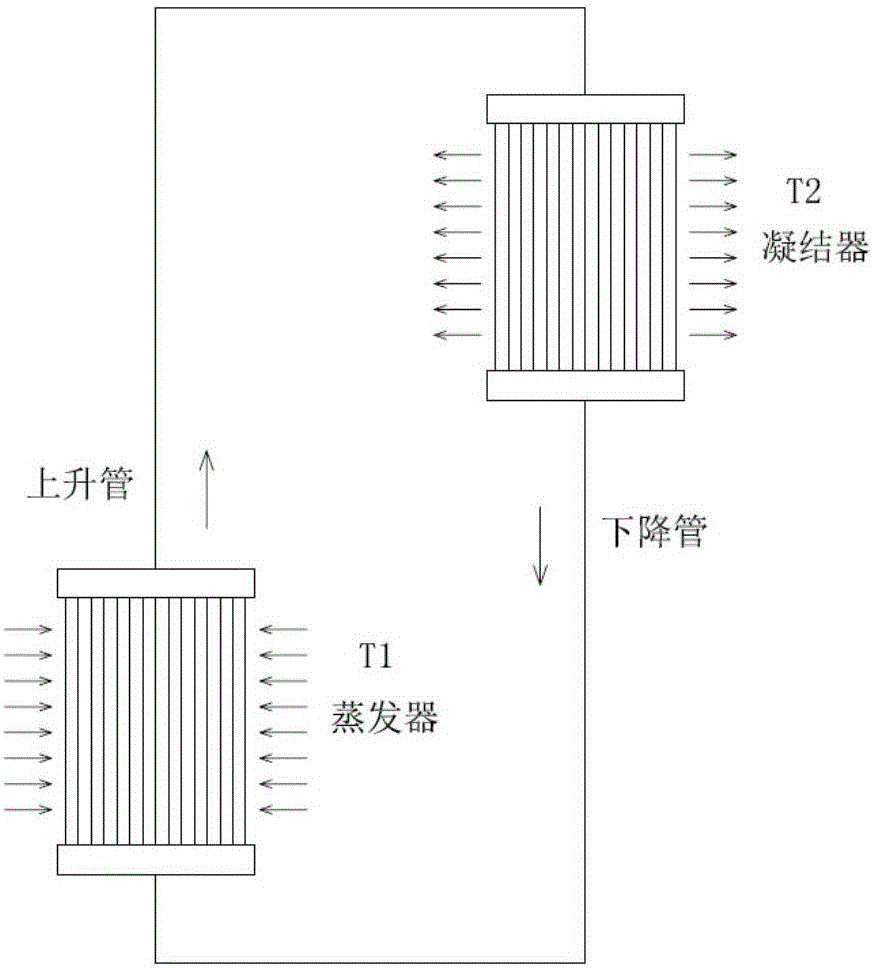

[0029] figure 1 It is a schematic diagram of the structure of the gravity loop heat pipe system. Such as figure 1 As shown, the gravity loop heat pipe system takes the passive containment cooling system as an example.

[0030] The data center cooling system of this embodiment uses the working principle of the separated heat pipe:

[0031] The evaporating section and the condensing section of the separated heat pipe are separated, and are connected through a steam rising pipe and a liquid downpipe to form a natural circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com