Revolution precision measuring device used for inner support type shafting and connected with hollow shafting

A technology of rotary accuracy and measuring device, applied in the direction of measuring device, instrument, etc., can solve the problems of relatively high installation accuracy of plane mirror, influence, no detection of hollow shaft, etc., and achieve the effect of convenient and quick adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

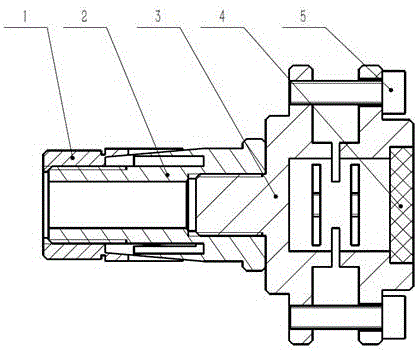

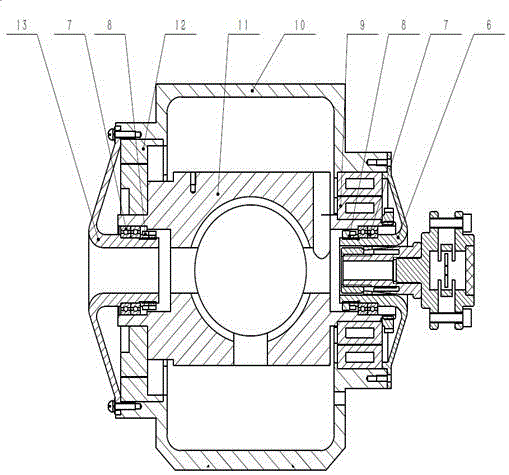

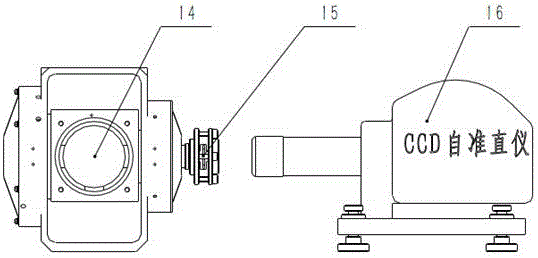

[0021] The internally supported shaft system rotation accuracy measuring device is mainly composed of an outer wedge-shaped sleeve 1, an inner wedge-shaped sleeve 2, a leveling bracket 3, a plane mirror 4, and an inner hexagon screw 5. The inner and outer wedge sleeves are thin-walled parts with tapered surfaces and four notches evenly distributed around the periphery, which have certain elasticity. The inner wedge sleeve 2 squeezes the outer wedge sleeve 1 through threads to make the outer wedge sleeve 1. Stretch out and connect with the measured hollow shaft system 14 by using friction force. By adjusting the inner hexagon screw 5 on the leveling bracket 3 to make the plane mirror 4 parallel to the CCD autocollimator 16, rotate the hollow shaft system 14, and use the CCD The autocollimator 16 measures the rotation accuracy of the shaft system.

[0022] The inner and outer wedge sleeves are thin-walled parts with tapered surfaces and four notches evenly distributed around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com