Temperature measurement device of cable joint and cable joint

A technology of cable joints and temperature measuring devices, which is applied in the direction of measuring devices, parts of connecting devices, coupling devices, etc., and can solve problems such as excessive volume, low temperature resistance insulation performance, and complicated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

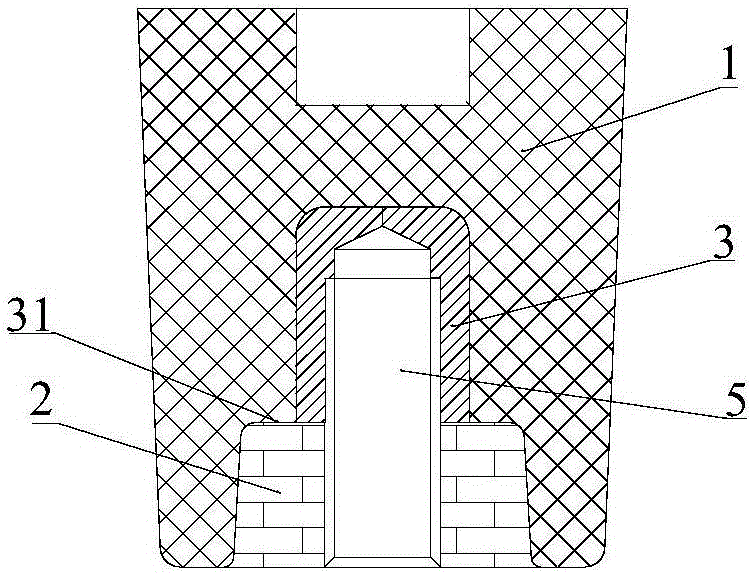

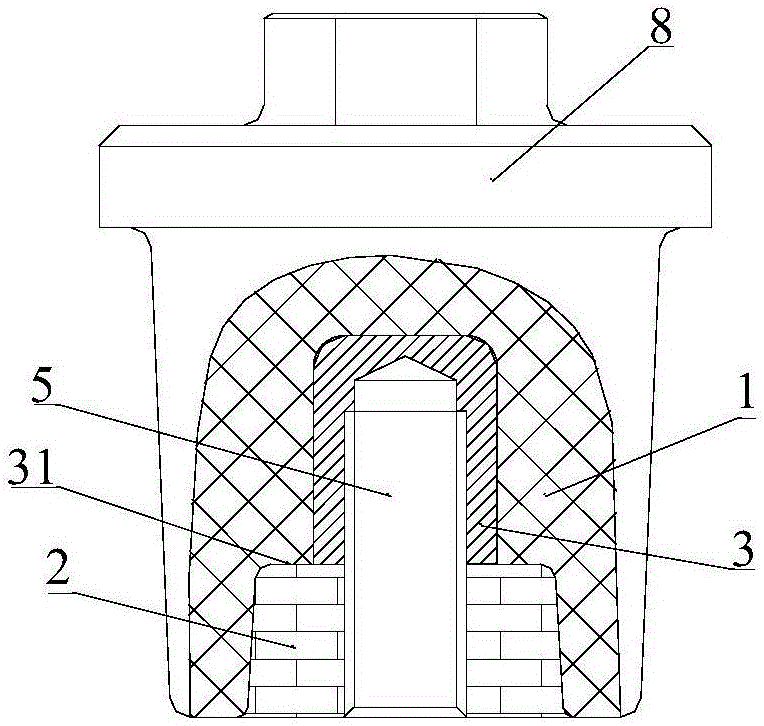

[0034] Such as figure 1 As shown, a temperature measuring device for a cable connector of this embodiment includes a rear plug cover 1 and a temperature measuring sensor device 2. One end of the back plug cover 1 is embedded with a metal insert 3, and the cable connector is wired The terminal 4 is fixedly connected to the metal insert 3, and the temperature sensing device 2 is crimped between the connection terminal 4 and the metal insert 3;

[0035] The temperature sensing device 2 is a SAW temperature sensor or a radio frequency identification sensor or a radio frequency sensor that can be powered by an electric field. The radio frequency identification sensor is a sensor that can work normally without external voltage. The radio frequency sensor that relies on electric field for electricity must have an external voltage to work, and the external voltage is above 2KV. In this embodiment, by directly contacting the heating point inside the cable joint through the temperature sen...

Embodiment approach

[0038] There are multiple implementations of the rear plug cover of this embodiment, which are specifically as follows:

Embodiment approach 1

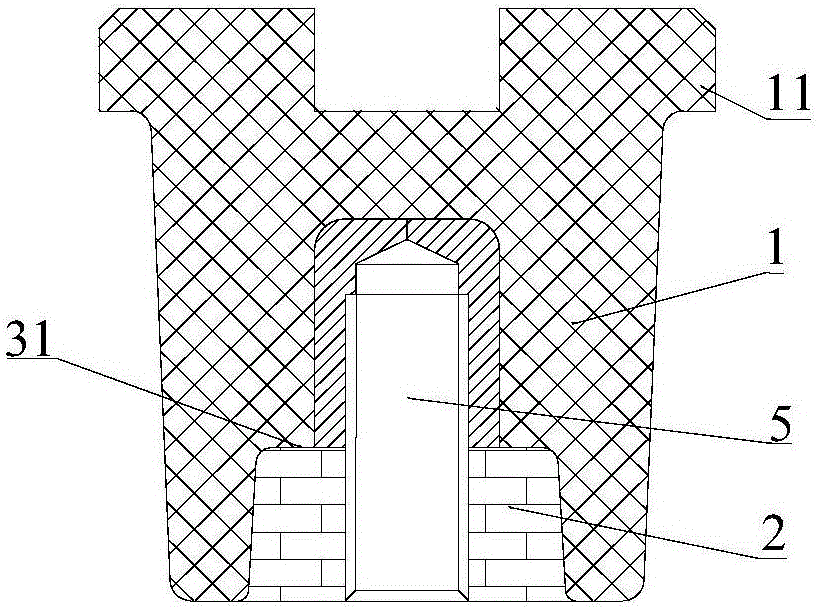

[0039] Implementation mode one: such as Figure 1-Figure 3 As shown, in this embodiment, the rear plug cover 1 has a cylindrical structure with one end blocked, the metal insert 3 is inserted and fixed to the open end of the rear plug cover 1, and the rear plug cover 1 is open. An annular step 12 is provided on the inner ring side of the end, and the annular step 12 is flush with the end of the metal insert 3; the temperature sensing device 2 is sleeved on the stud bolt by interference fit 5, one end of which is crimped on the annular step 12 and the metal insert 3, and the other end is flush with the open end of the rear plug cover 1. By crimping the temperature measuring sensor device on the annular step and the metal insert, the overall fixing is firmer.

[0040] The rear blocking cover 1 of this embodiment may be a cylindrical shape with a smooth outer wall, such as figure 1 As shown; it is also possible to set a circumferentially arranged outer edge 11 on the outer wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com