Heat dissipation electrical cabinet with electrical automatic control and alarm system thereof

A technology of electrical automation and electrical cabinets, which is applied in the direction of alarms, electrical components, substation/power distribution device shells, etc., which can solve the problems of electrical components damage, waste, energy consumption, etc. in electrical cabinets, achieve safe and convenient use, and prolong discharge time , Structural scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

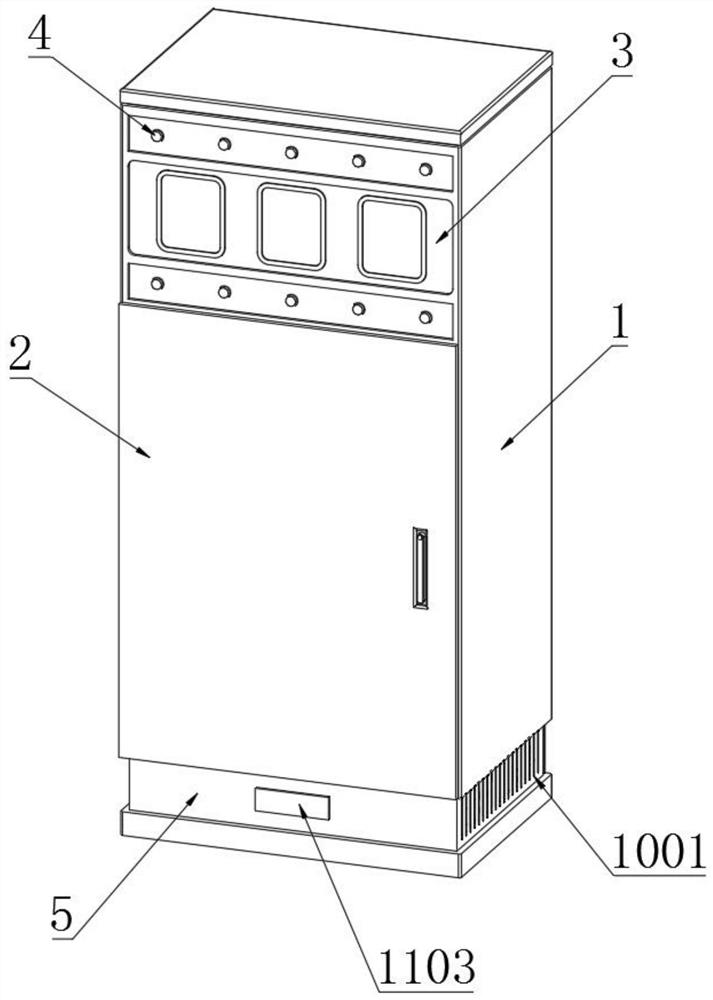

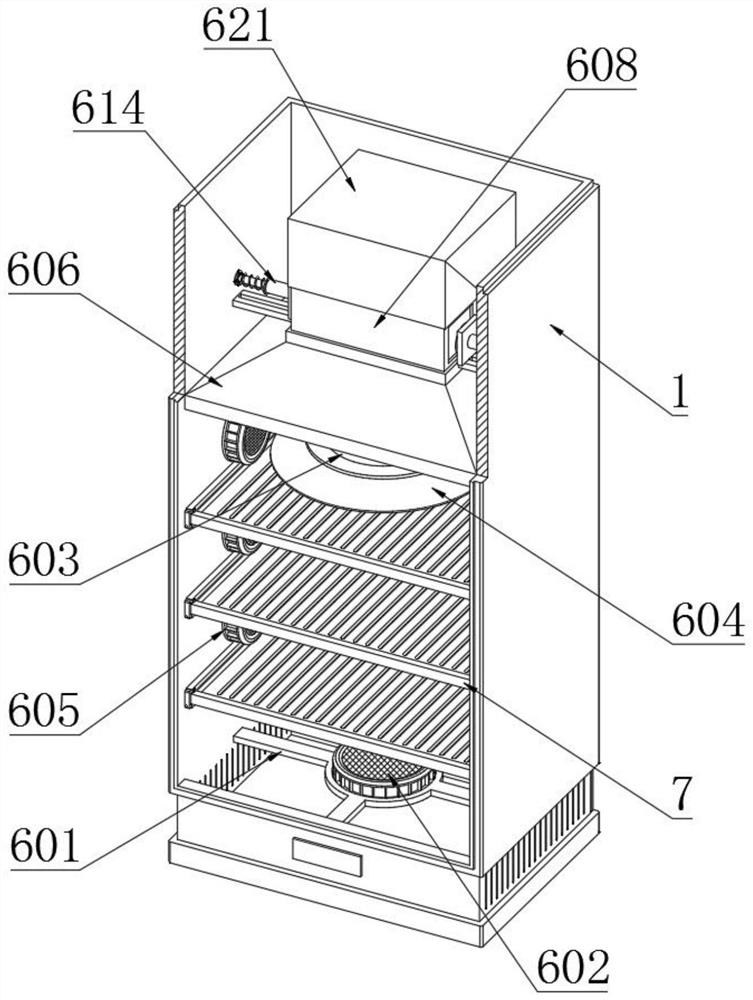

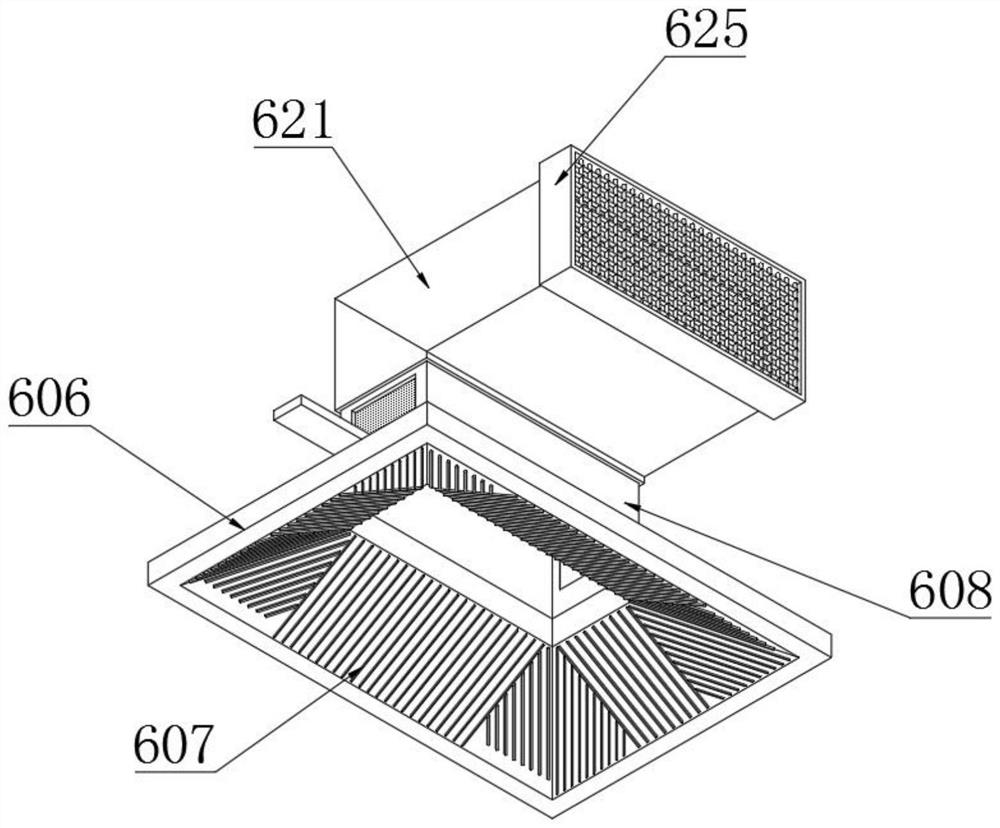

[0047] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a heat dissipation electrical cabinet controlled by electrical automation, including an electrical cabinet body 1, a cabinet door 2 is hinged on the outer end surface of the electrical cabinet body 1, and a display is embedded on the front end surface of the top of the electrical cabinet body 1. Panel 3, a warning light 4 is set at the side of the display panel 3, the bottom of the electrical cabinet body 1 is fixedly connected with a base 5, and an energy-saving heat dissipation component 6 is installed on the inside top of the electrical cabinet body 1, and the energy-saving heat dissipation component 6 includes a fan bracket 601, a second A cooling fan 602, a second cooling fan 603, a gas collecting hood 604, an auxiliary cooling fan 605, a heat collecting cone 606, a heat conducting metal strip 607, a heat collecting runner 608, a fixed bracket 609, a movable plate 610, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com