A novel device and method capable of realizing friction identification of all components

A component, a new type of technology, applied in measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as reducing the accuracy of friction models, reducing friction due to system dynamic responsiveness, and improving overall performance indicators. Improve accuracy, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

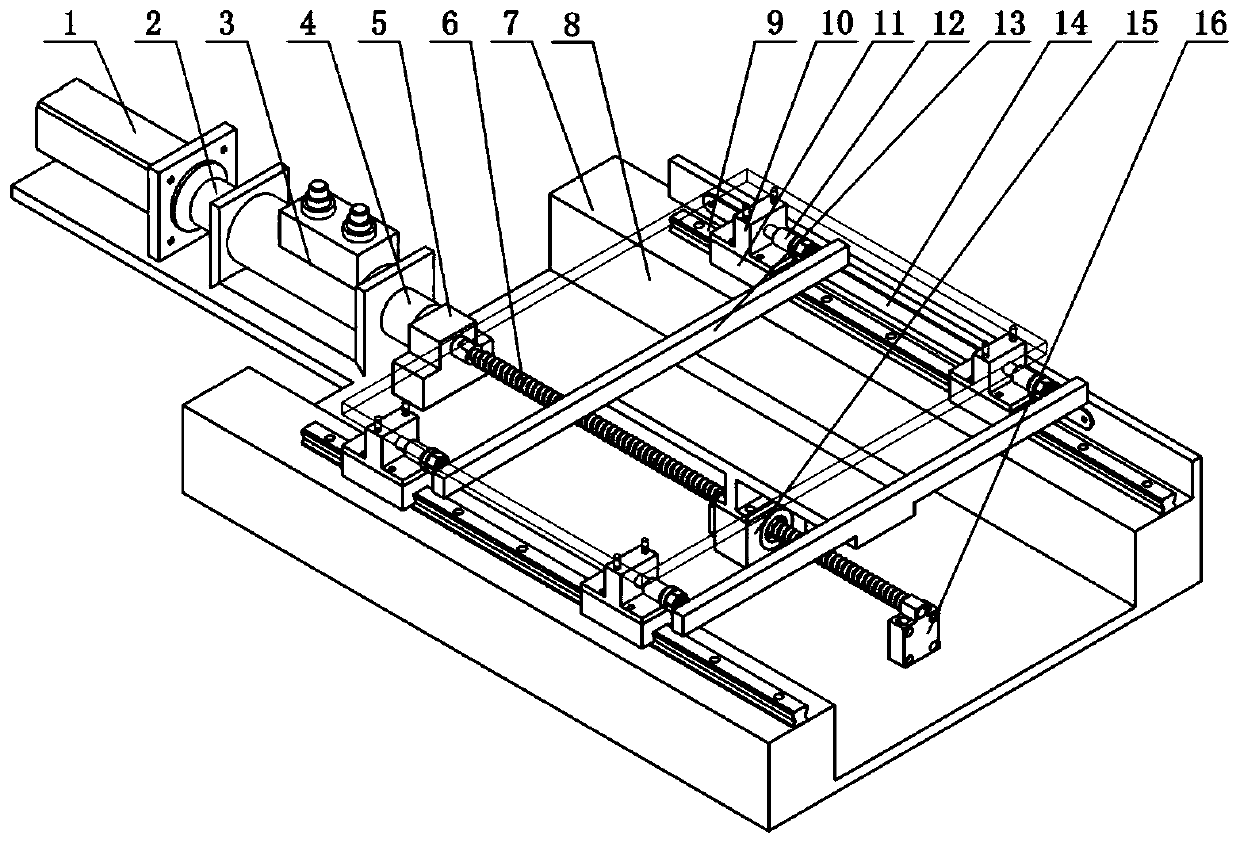

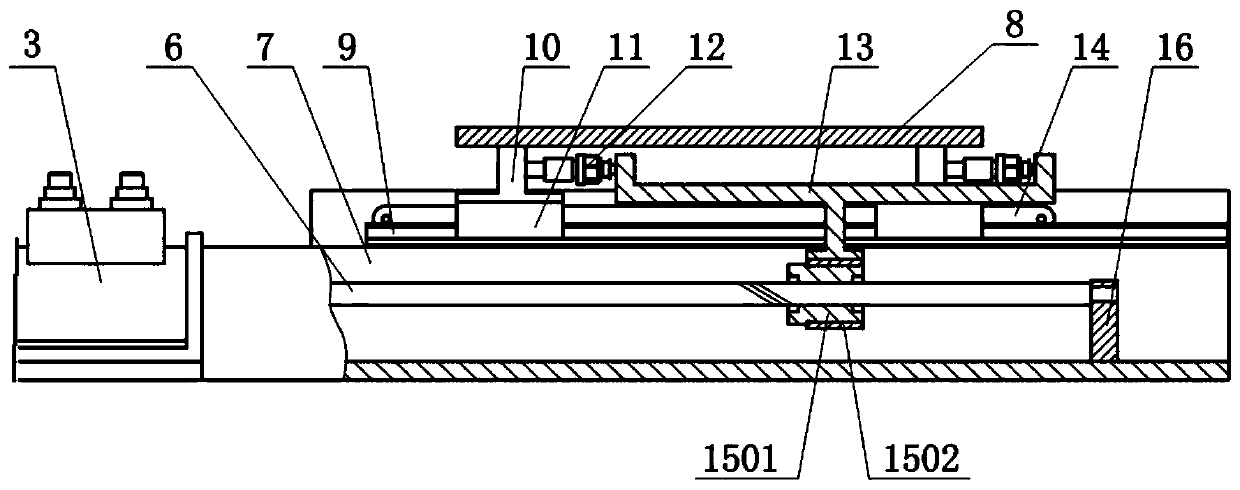

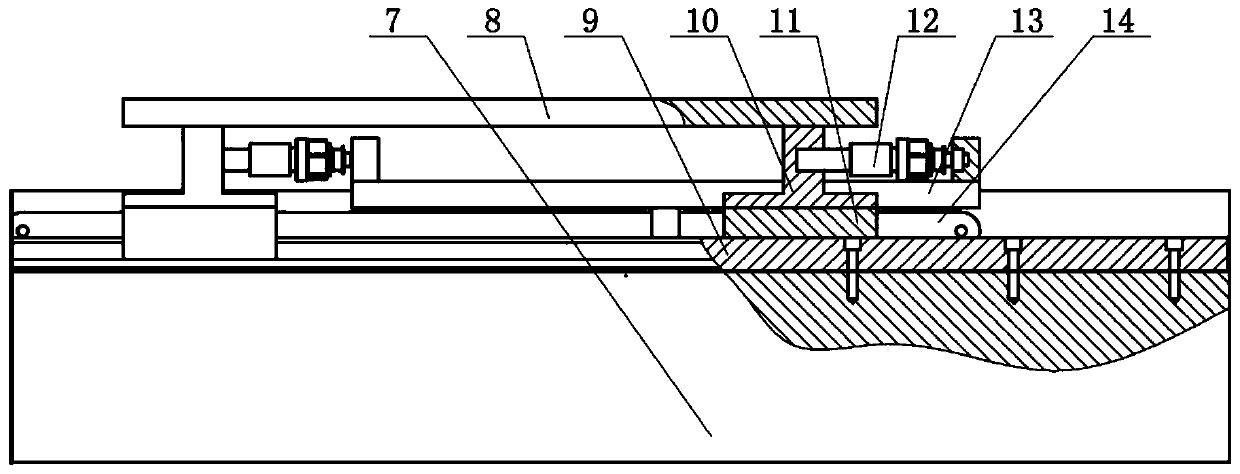

[0024] like Figure 1-3 As shown, the new experimental device disclosed by the present invention that can realize friction identification of all components is composed of a motor 1, a coupling 2, a torque sensor 3, a coupling 4, a lead screw support seat 5, a lead screw 6, a base 7 , worktable 8, guide rail 9, worktable support block 10, slider 11, force sensor 12, connecting frame 13, grating ruler 14, screw nut block 15, screw support seat 16, the motor 1 drives the The lead screw 6 drives the table 8 to move along the guide rail 9 through the lead screw nut block 15; the specific structure is as follows:

[0025] The motor 1 is arranged on the base 7, the motor 1 drives the lead screw 6 to rotate, and the torque sensor 3 is connected between the motor 1 and the lead screw 6; the lead screw 6 drives a lead screw nut block 15 to slide back and forth along it , the lead screw nut block is driven with a connecting frame 13 to move together with it; there are two parallel guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com