Method for determining widths of partition coal pillars at slope based on creep test of coal sample

A determination method and coal sample technology, applied in the field of determination of the width of the isolated coal pillar of the slope based on the creep experiment of the coal sample, can solve the problems of the research on the setting system of the width of the isolated coal pillar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention provides a method for determining the width of a slope-isolated coal pillar based on a coal sample creep experiment, which is implemented on the spot in a coalfield mining area in Inner Mongolia, including the following steps:

[0022] Step 1, collect coal samples, and determine that the time for the shearer to complete a recovery in the mining area is 3 days;

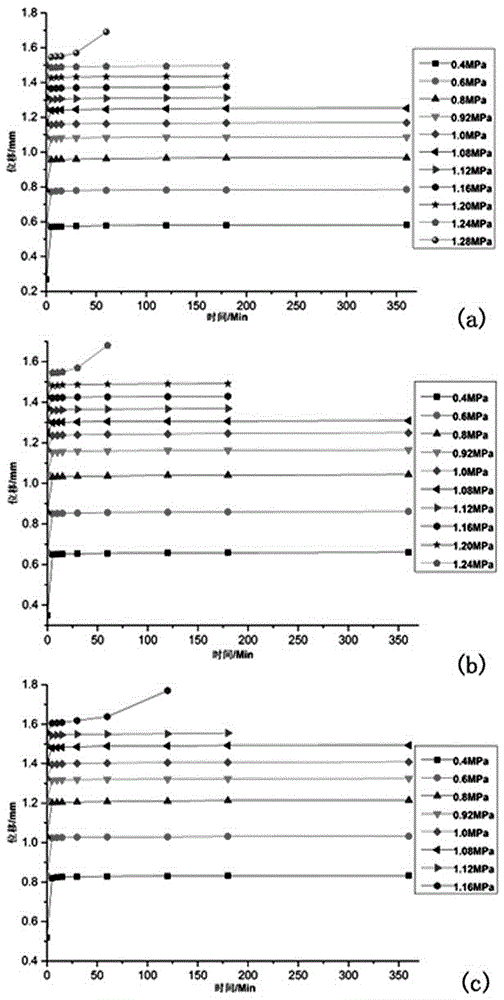

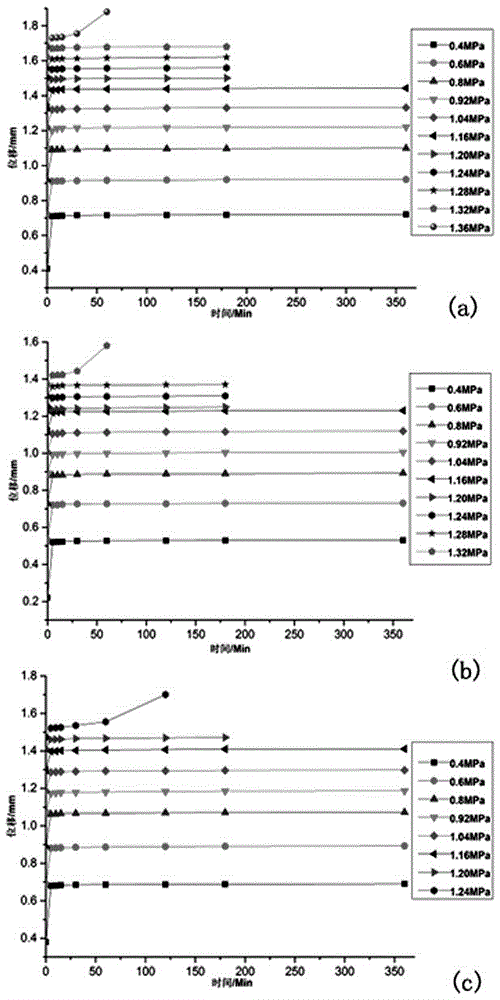

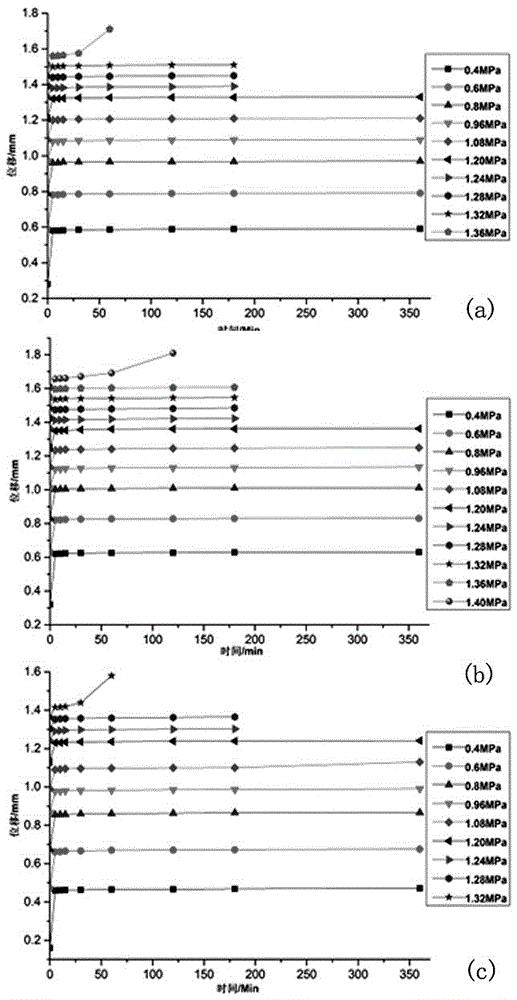

[0023] Step 2: Divide the coal sample into 9 parts, take 3 days as the failure time of each coal sample on the testing machine, and set three levels of normal stress: 0.6MPa, 0.8MPa, 1.0MPa, and use Chen's The graded loading method sets the horizontal stress corresponding to the normal stress of each level, at 0.4~1.36MPa, and implements the creep failure test of the coal sample within one recovery time, and the creep failure test of each level of normal stress corresponds to 3 coal samples, and obtain the creep stress-strain curves of coal samples under different normal stresses (such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com