Measurement method of plastic tensile strength of cement-base material

A cement-based material, tensile strength technology, applied in the field of material science and engineering, can solve the problem of difficulty in establishing test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

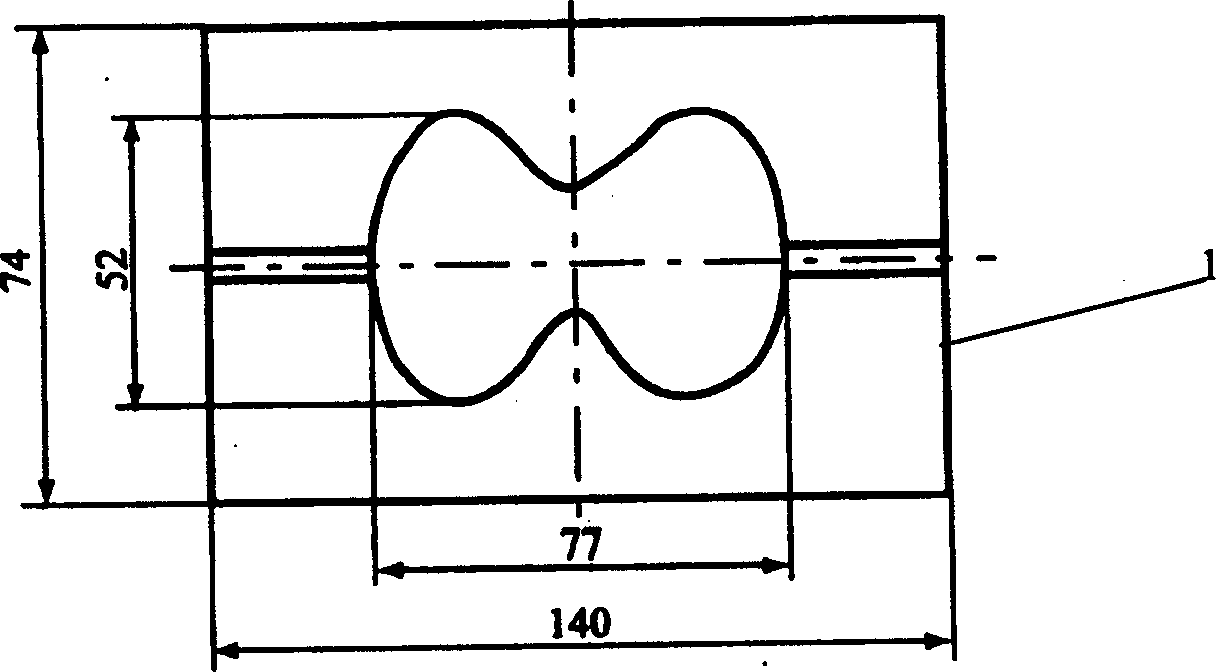

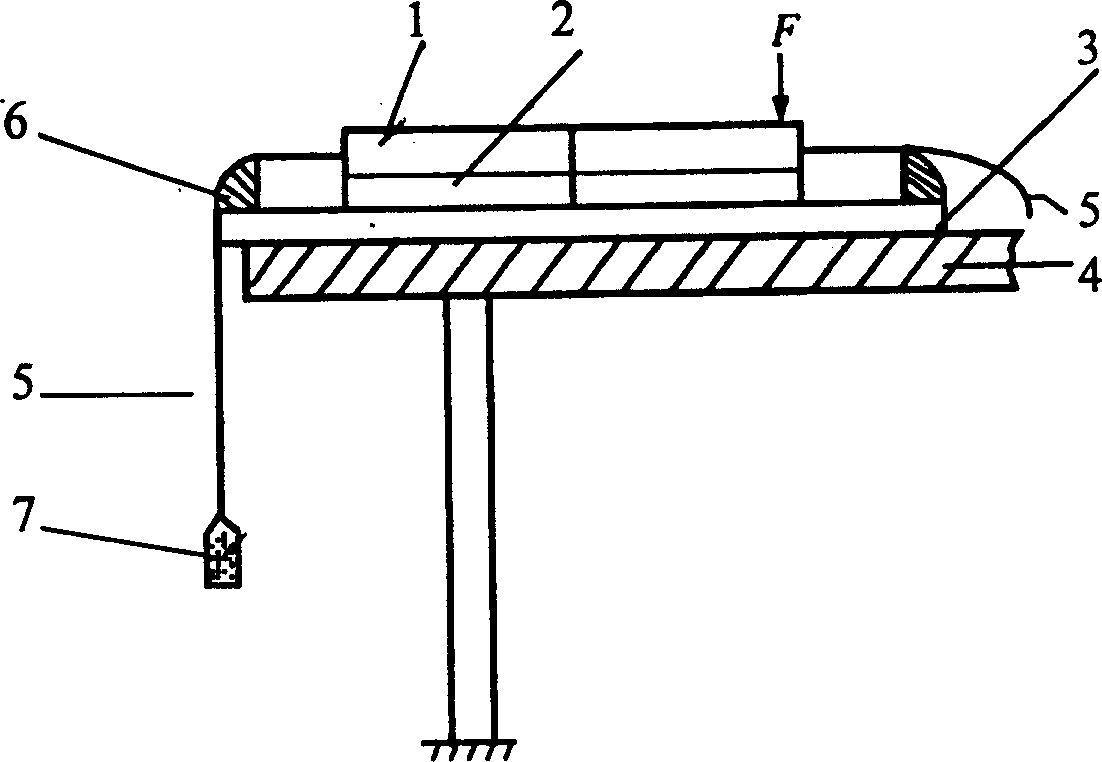

[0027] Take the 8-shaped mold as an example below to further elaborate the present invention.

[0028] 1. Make plastic tensile strength test mold

[0029] The mold consists of two symmetrical 8-shaped mold halves, such as figure 1 shown. Each half-mold base plate is flush with the 8-shaped half-mold opening, and two 8-shaped half-molds connected with the base plate 2 can just be combined into a complete 8-shaped mold 1. A perforation is respectively opened at the two ends centers of the two 8-shaped half-moulds, and the cords are inserted and fixed in the half-moulds; The 8-shaped mold formed by pairing two 8-shaped half-molds is placed on a whole flat supporting plate 3. The upper surface of the pallet and the lower surface of the bottom plate should be flat and smooth, or rollers should be installed between them to reduce the friction during relative movement. When testing cement paste and mortar, a small-sized 8-shaped mold is used, and when testing concrete, a larger-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com