Gas engine lubricating oil composition and preparation method and application thereof

A lubricating oil composition and gas engine technology, applied in the field of lubricating oil, can solve the problems of increased working temperature of lubricating oil, poor heat dissipation, increased wear of gas engine, etc. obvious effect

Inactive Publication Date: 2017-05-03

CHINA PETROLEUM & CHEM CORP

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to the high combustion temperature of the gas engine and the lack of lubricity of the gas itself, the gas engine has strict requirements on the deposits. Excessive deposits will cause problems such as increased wear, increased energy consumption, and poor heat dissipation of the gas engine.

In the actual application of the traditional I, II, III, and IV base oils blended in a certain form, the gas engine lubricating oil still has a lot of deposits, which leads to aggravated wear and an increase in the operating temperature of the lubricating oil. , leading to accelerated oxidation and deterioration of lubricating oil, thus shortening the service life of lubricating oil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0034] Example 1: Gas Engine Lubricating Oil Composition

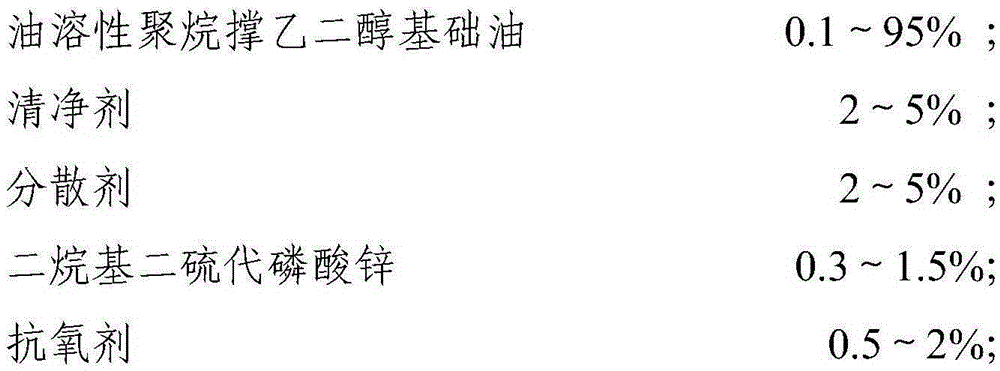

[0035] The composition consists of:

[0036]

Embodiment 3

[0039] Example 3: Gas Engine Lubricating Oil Composition

[0040] The composition consists of:

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Login to View More

Abstract

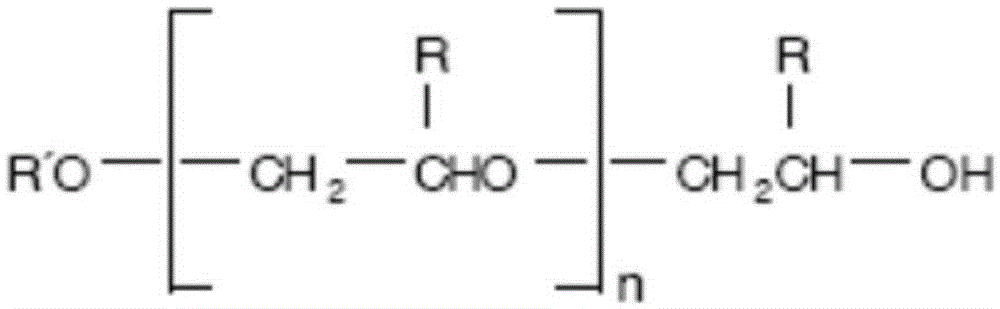

The invention relates to a gas engine lubricating oil composition which is formed by mixing oil soluble polyalkylene glycol base oil, a clearing agent, a dispersing agent, zinc dialkyl dithiophosphate, an antioxidant, a pour point reducer and neutral base oil in a certain proportion. The invention further relates to a preparation method of the gas engine lubricating oil composition and application of the gas engine lubricating oil composition. According to the gas engine lubricating oil composition, the phenomenon that a large amount of sediment exists in existing gas engine lubricating oil is avoided, the defects that abrasion is intensified, working temperature of lubricating oil is increased and oxidative deterioration of lubricating oil is accelerated due to the fact that a large amount of sediment exists in existing gas engine lubricating oil are overcome, and the service life of lubricating oil is prolonged.

Description

technical field [0001] The invention relates to the field of lubricating oil, in particular to a lubricating oil composition for a gas engine. Background technique [0002] Due to the high combustion temperature of the gas engine and the lack of lubricity of the gas itself, the gas engine has strict requirements on the deposits. Excessive deposits will cause problems such as increased wear, increased energy consumption, and poor heat dissipation of the gas engine. In the actual application of the traditional I, II, III, and IV base oils blended in a certain form, the gas engine lubricating oil still has a lot of deposits, which leads to aggravated wear and an increase in the operating temperature of the lubricating oil. , leading to accelerated oxidation and deterioration of the lubricating oil, thereby shortening the service life of the lubricating oil. Therefore, finding a base oil component that does not generate deposits and has a certain inhibitory effect on the format...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M107/34C10M141/08C10M157/10C10N40/25C10N20/02C10N30/04C10N30/10

Inventor 黄海鹏朱和菊赵心怡孟雪梅赵佳洋张星宇

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com