A kind of lubricating oil composition for electric vehicle gearbox and preparation method thereof

A lubricating oil composition and electric vehicle technology, applied in the field of lubricating oil, can solve the problem of oil-to-seal, low-temperature rheological electro-magnetic compatibility, inability to provide anti-extreme pressure gear protection, oil viscosity retention, It cannot meet the problems of two-stage or multi-stage gearboxes, and achieves the effects of excellent bearing and gear extreme pressure protection and anti-pitting corrosion protection, excellent thermal oxidation stability, and improved cleansing and dispersing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

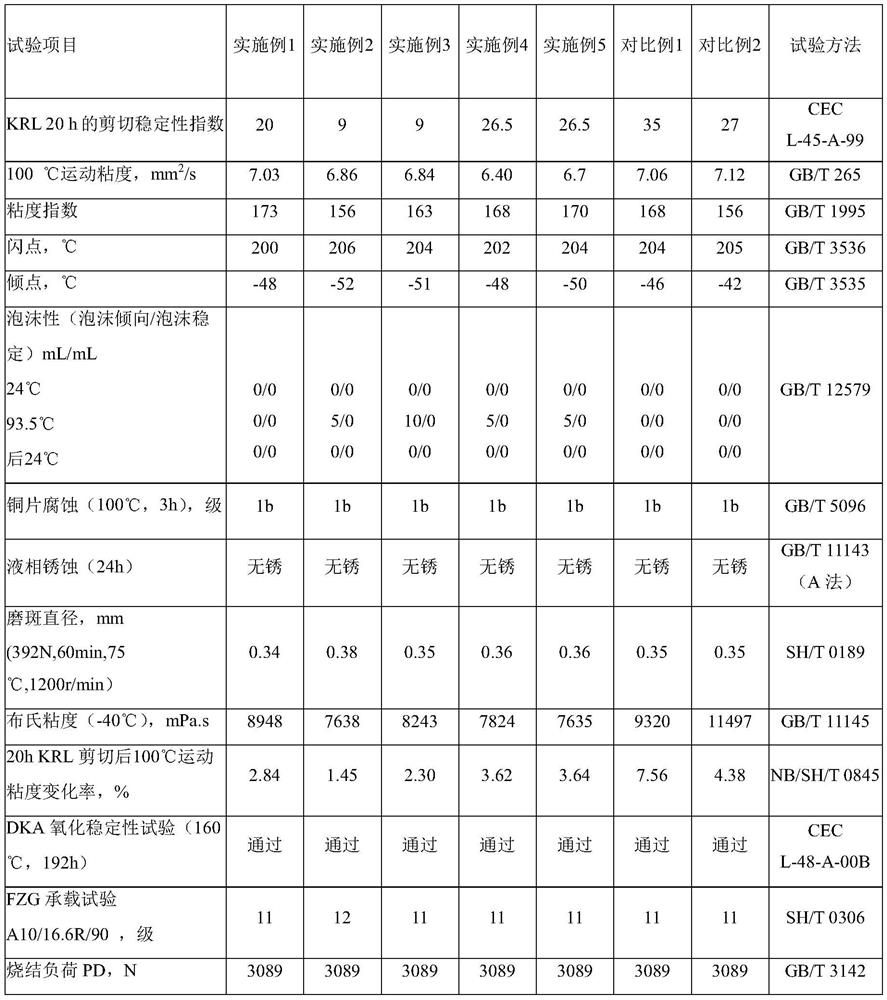

Embodiment 1

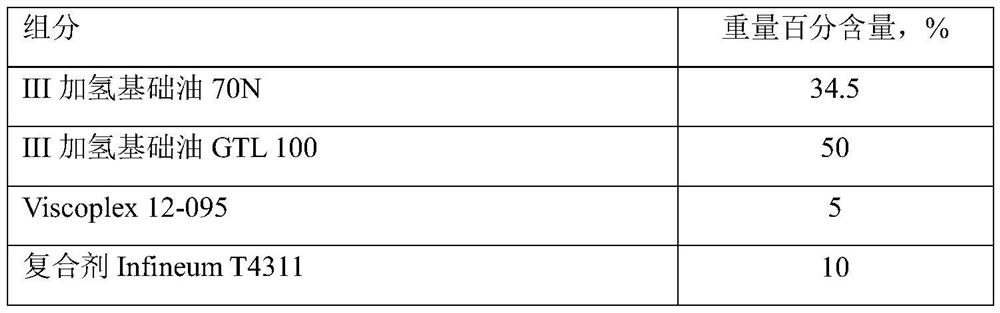

[0016] The lubricating oil composition for electric vehicle transmission in this example is blended from the components in weight percentage in Table 1, and its performance index data are shown in Table 8.

[0017] Raw material components and weight percentages of Table 1 Example 1

[0018] components Weight percentage, % III hydrogenated base oil 70N 58.2 Polyalphaolefin base oil PAO6 22 Viscoplex 0-051 6.5 Complex agent HITEC 2468 12.8 Pour point depressant Viscoplex 1-300 0.5

Embodiment 2

[0020] The lubricating oil composition for electric vehicle transmission in this example is prepared by blending the components in weight percent in Table 2, and its performance index data are shown in Table 8.

[0021] Raw material component and weight percentage of table 2 embodiment 2

[0022] components Weight percentage, % III hydrogenated base oil 70N 30 III hydrogenated base oil 150N 49.8 Viscoplex 12-075 7.0 Complex agent HITEC 2468 12.8 Pour point depressant Viscoplex 1-248 0.4

Embodiment 3

[0024] The lubricating oil composition for electric vehicle transmission in this example is blended from the components in weight percent in Table 3, and its performance index data are shown in Table 8.

[0025] Raw material component and weight percentage of table 3 embodiment 3

[0026] components Weight percentage, % III hydrogenated base oil 100N 27.3 Polyalphaolefin base oil PAO4 53 Viscoplex 12-075 6.5 Complex agent HITEC 2468 12.8 Pour point depressant Viscoplex 1-248 0.4

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| shear stability index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com