High-strength self-locking automatic connecting mechanism

An automatic connection and self-locking technology, which is applied in the direction of mechanical equipment, transmission components, transmission devices, etc., can solve the problems of short service life of the track, deviation of the docking positioning method, etc., and achieve the effect of improved positioning and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

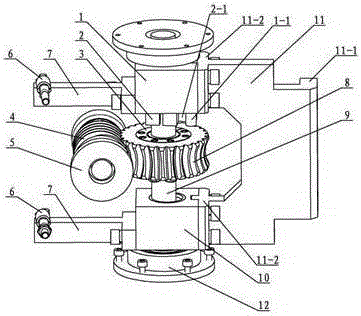

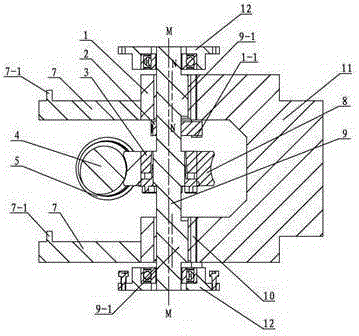

[0008] Combining Figure l and figure 2 , the large output self-locking automatic connection mechanism includes the first rotating block 1, the limit block 2, the expansion sleeve 3, the worm 4, the worm wheel 8, the camshaft 9, the second rotating block 10, the movable hook 11, two A worm bearing seat 5, two return springs 6, two spring connecting rods 7 and two camshaft seats 12, the first rotating block 1, the limit block 2, the expansion sleeve 3 and the second rotating block 10 from top to bottom The bottom is arranged on the camshaft 9 in turn, and the connection between the second rotating block 10 and the camshaft 9 is the eccentric shaft 9-1. The purpose of the eccentric shaft 9-1 is to continue to rotate when the movable hook 11 reaches the position. Pull the first rotating block 1 and the second rotating block 10 back to the locked state, the upper and lower ends of the camshaft 9 are respectively connected to the two camshaft seats 12 through bearings, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com