Multistage differential fresh tea leaf sorting and single-column conveyor and single-column conveying method thereof

A conveyor and differential speed tea technology, applied in the field of machinery, can solve the problems of large damage, low efficiency, inaccurate classification of tea leaves, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

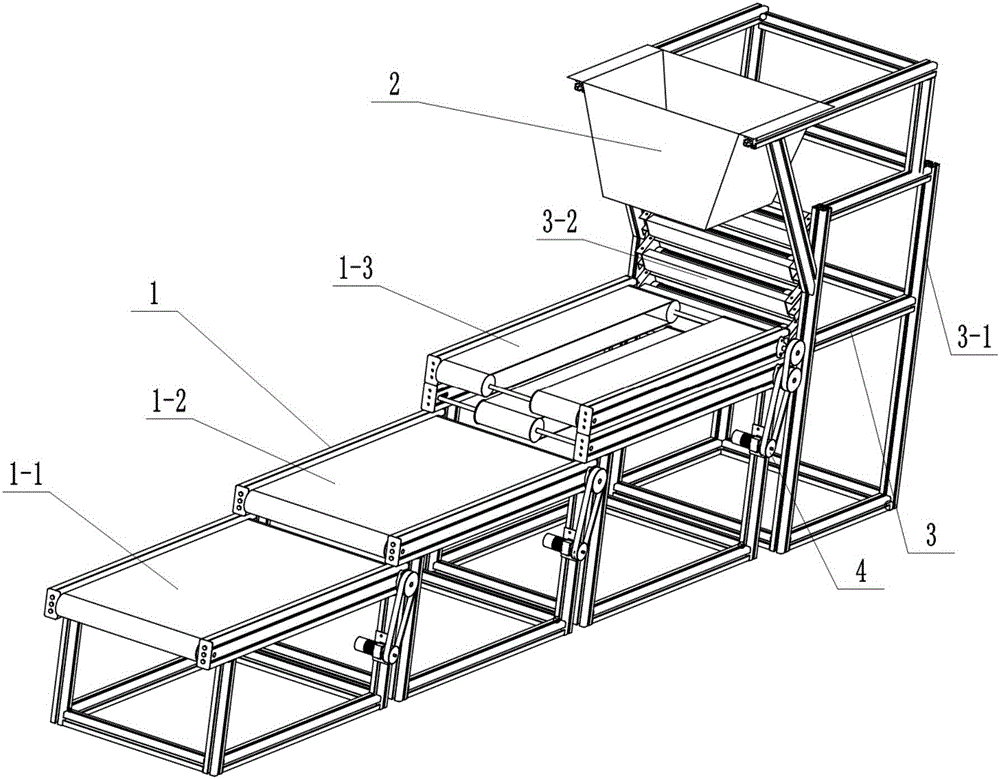

[0027] like figure 1 As shown, the multi-stage differential conveyor for sorting fresh tea leaves includes a multi-stage differential conveyor 1, an unloader 2, and a cross-flow fan group system 3; the cross-flow fan group system 3 is set in the multi-stage differential conveying The input end of the machine 1; the cross-flow fan group system 3 is composed of the fan support frame 3-1 and the cross-flow fan 3-2; the four cross-flow fans 3-2 are fixed on the fan support frame 3-1 by bolts up and down equidistant ; Each cross-flow fan has an independent fan speed controller control. The unloader 2 is arranged on the top of the cross-flow fan 3-2 at the highest position, and is fixed on the fan support frame 3-1.

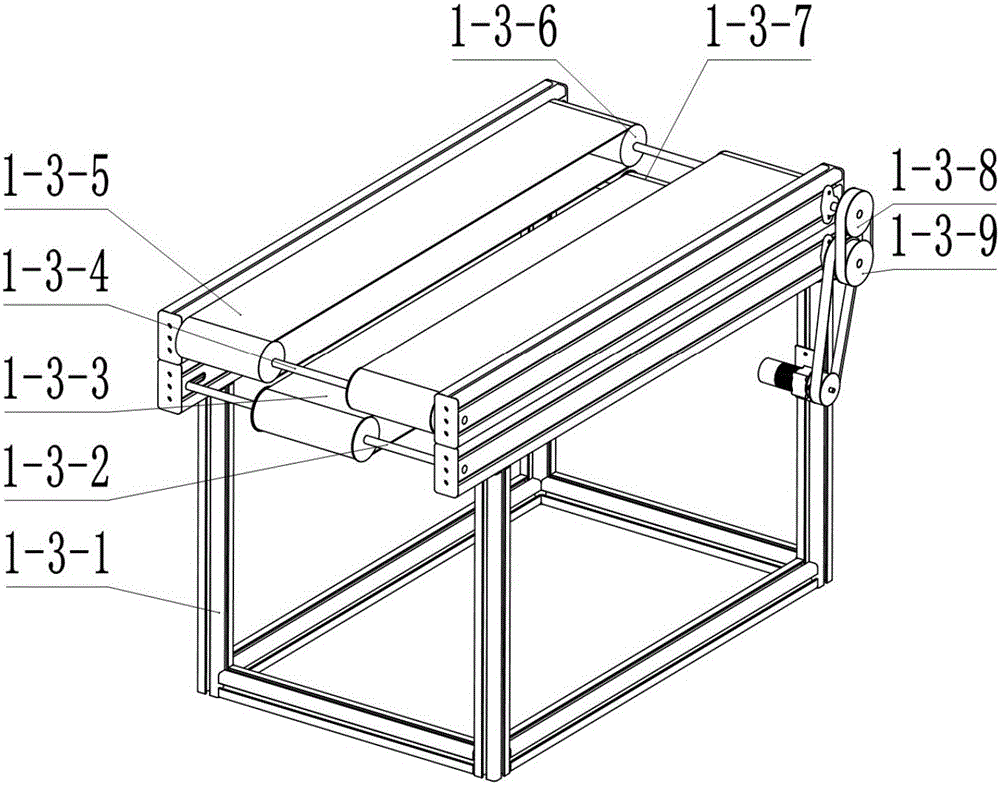

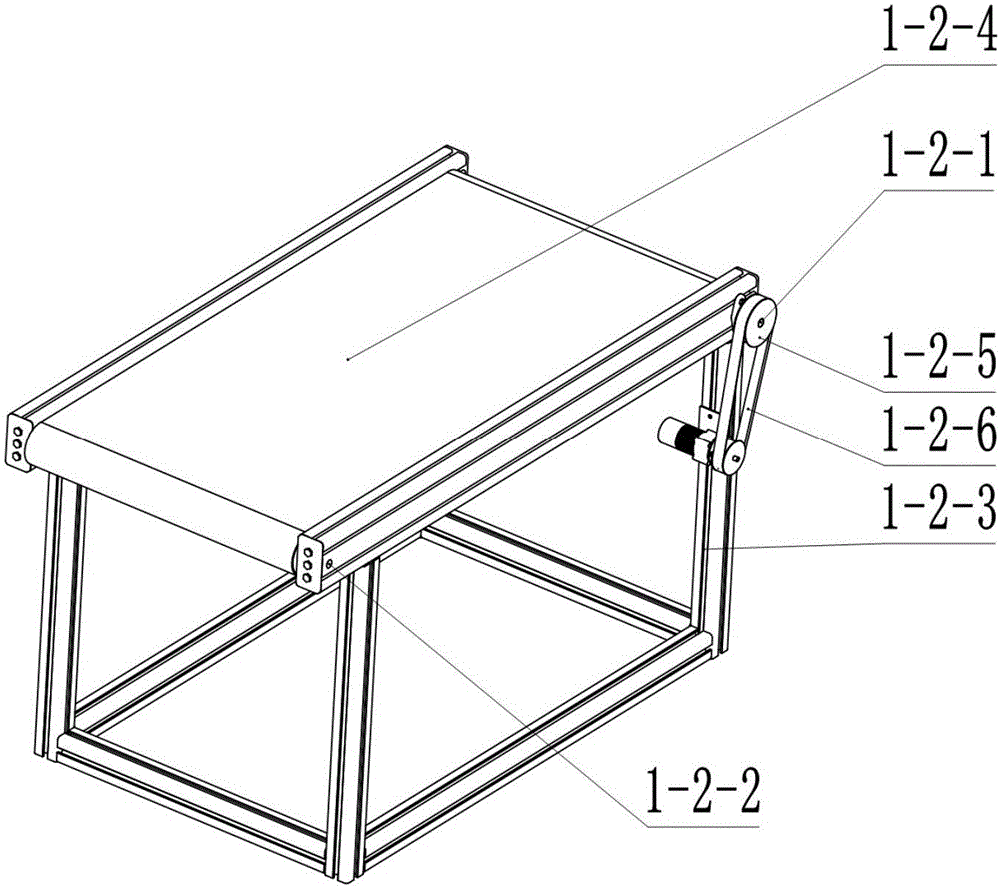

[0028] like figure 1 , 2As shown in and 3, the multistage differential conveyor 1 includes a double-layer conveyor 1-3, a secondary conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com