Method of conducting classified packaging based on size of tobacco flake

A size and tobacco sheet technology, which is applied in the field of classification and packaging based on the size of tobacco sheets after threshing and rebaking, can solve the problems of not paying attention to the physical form, and achieve the effects of small changes, easy implementation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

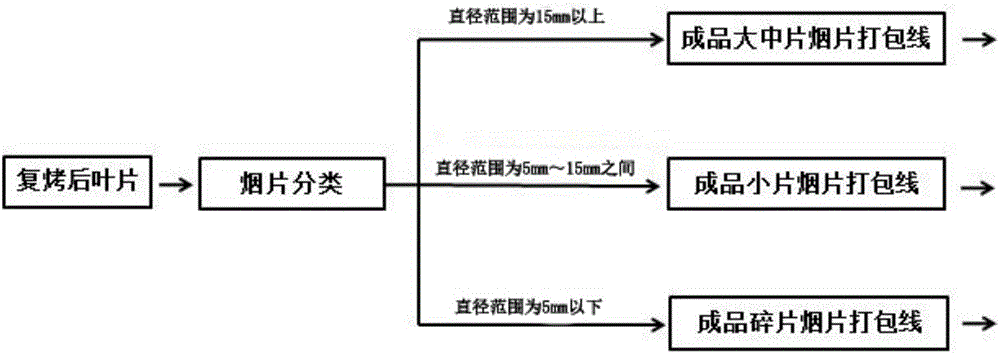

[0017] Such as figure 1 As shown, a method of sorting and packaging based on the size of tobacco sheets. In the process of threshing and re-baking, the leaves after threshing and re-baking are classified according to the size of the leaves, and then packaged into finished tobacco according to the specifications. Bag.

[0018] The classification preferably adopts an orifice vibrating screen.

[0019] The classification principle is as follows: according to the diameter of the leaves, the leaves are divided into three categories: large and medium pieces, small pieces, and fragments. Among them, the leaves with a diameter range of 15 mm or more are large and medium pieces, and the leaves with a diameter range of 5 mm to 15 mm It is a small piece, and the leaves with a diameter range of less than 5mm are fragments.

[0020] After different leaves are sorted and packaged, they are sent to the warehouse for targeted alcoholization and use as rebaked finished cigarette packs.

[0...

Embodiment 2

[0023] A method for classifying and packaging tobacco sheets based on the size of the tobacco sheets. In the process of threshing and re-baking, the leaves after threshing and re-baking are classified according to the size of the leaves, and then packed into finished cigarette packs according to specifications.

[0024] The classification is based on the principles: according to the diameter of the leaves, the leaves are divided into four categories: large, medium, small, and fragments. Among them, the leaves with a diameter of more than 20 mm are large, and the leaves with a diameter of 10 mm to 25 mm are medium. The leaves with a diameter ranging from 5mm to 15mm are small pieces, and the leaves with a diameter of less than 5mm are small pieces.

[0025] The classification preferably adopts an orifice vibrating screen.

[0026] After different leaves are sorted and packaged, they are sent to the warehouse for targeted alcoholization and use as rebaked finished cigarette pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com