Roller mechanism and cigarette block pre-loosening treatment device

A technology of roller conveying mechanism and cigarette blocks, which is applied to tobacco, conveyor, tobacco preparation, etc., can solve the problems of unfavorable production, difficult to achieve uniform material pushing, increase material crushing rate, etc., so as to reduce processing strength and energy consumption. , Conducive to long-term use and uniform material removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

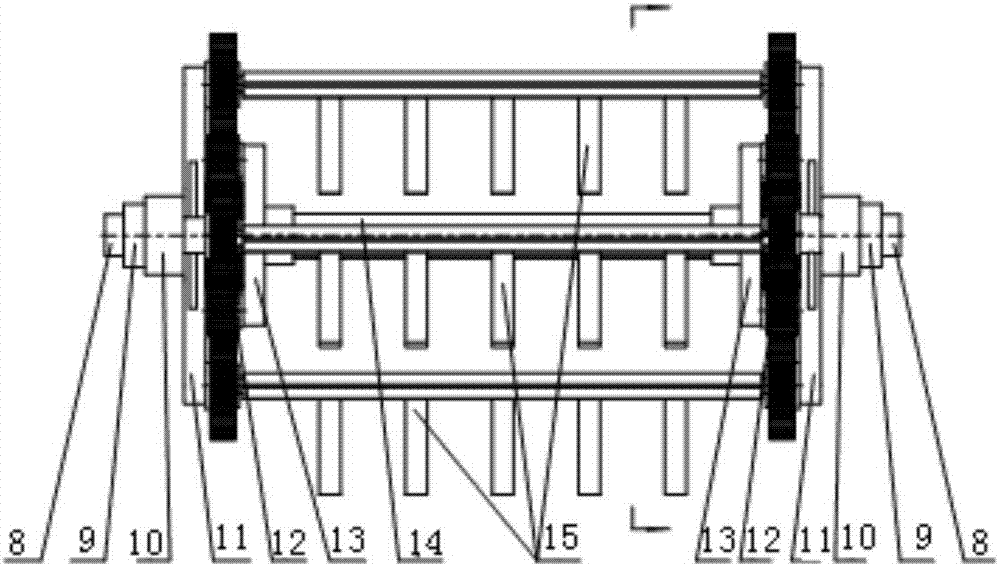

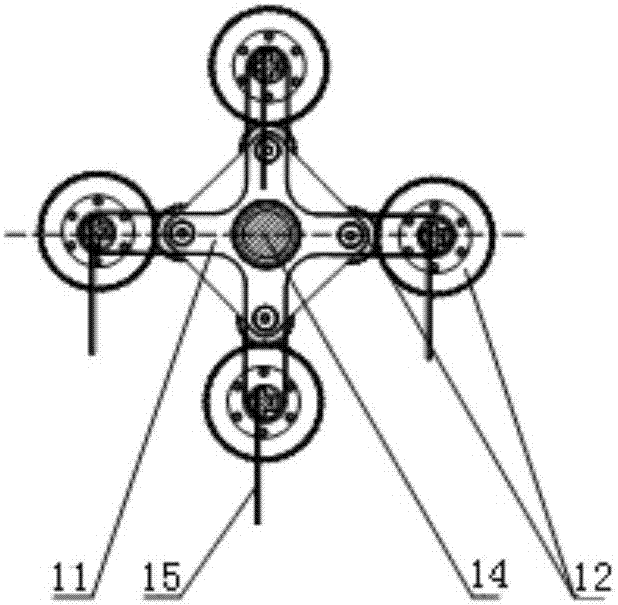

[0037] The roller mechanism 6 includes a main shaft 9 for power input, such as figure 2 and image 3 As shown, two sets of planetary gear trains are set at a set distance on the main shaft 9. The planetary gear train includes a planetary carrier 11. The main shaft 9 is coaxially connected with the planetary carrier 11 through a shift roller bracket 10. The planetary carrier 11 and the main shaft revolve around the main shaft 9 itself. The axis realizes synchronous rotation movement, the fixed shaft 8 passes through the shaft hole of the main shaft 9 and the planet carrier 11, and the sun gear is positioned at the center of the planet carrier 11, and the transition wheel 20 and the planet wheel 19 are both arranged on the support wall of the planet carrier 11 , the planet carrier 11 is provided with 4 support arms, the planetary gear, the transition wheel 20 and the sun gear 21 are all driven by cylindrical gears, and the number of teeth of the planetary gear and the sun gear ...

Embodiment 2

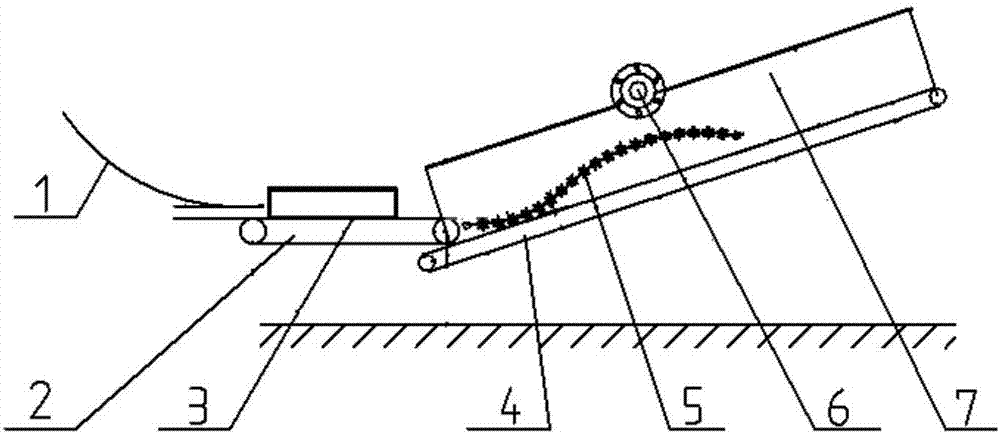

[0044] A kind of cigarette block pre-loose treatment device, such as figure 1 shown, including:

[0045]The arc-shaped roller conveying mechanism 5 is set above the belt conveyor. Each roller in the roller conveying mechanism 5 is connected with the power mechanism. By adjusting the speed of the rollers step by step, the linear speed of the latter roller is greater than that of the previous roller. The linear speed of the grade roller realizes the tearing of the cigarette block 3 on the roller conveying mechanism 5 .

[0046] The above-mentioned cigarette block pre-loosening treatment device, by setting the arc-shaped roller table conveying mechanism 5, can realize the stretching and compression of the upper and lower sides of the cigarette block through the arc-shaped curve formed by the roller table, and the adjacent rollers have different heights. , it is beneficial to generate cracks inside the cigarette block 3, and when two adjacent rollers have different linear speeds,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com