A heating water tank with a heat-insulating observation window and a load-bearing lifting device

A lifting device and heating water tank technology, which is applied in the field of medical equipment, can solve the problems that the heating water tank does not have an observation window or a cover and a window, the fogging of the glass affects the user's observation of the tank, and the manual lifting operation is inconvenient, so that it is not easy to be heated Burning, avoiding personnel burns, easy to take and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

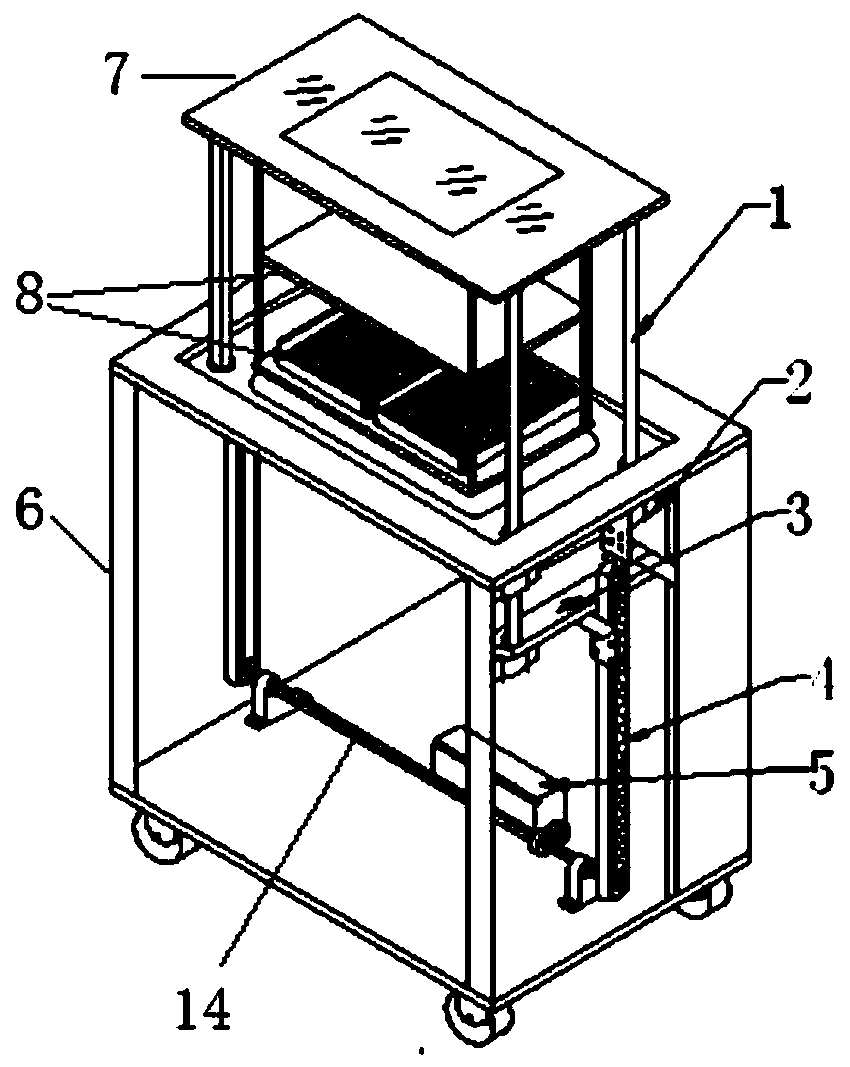

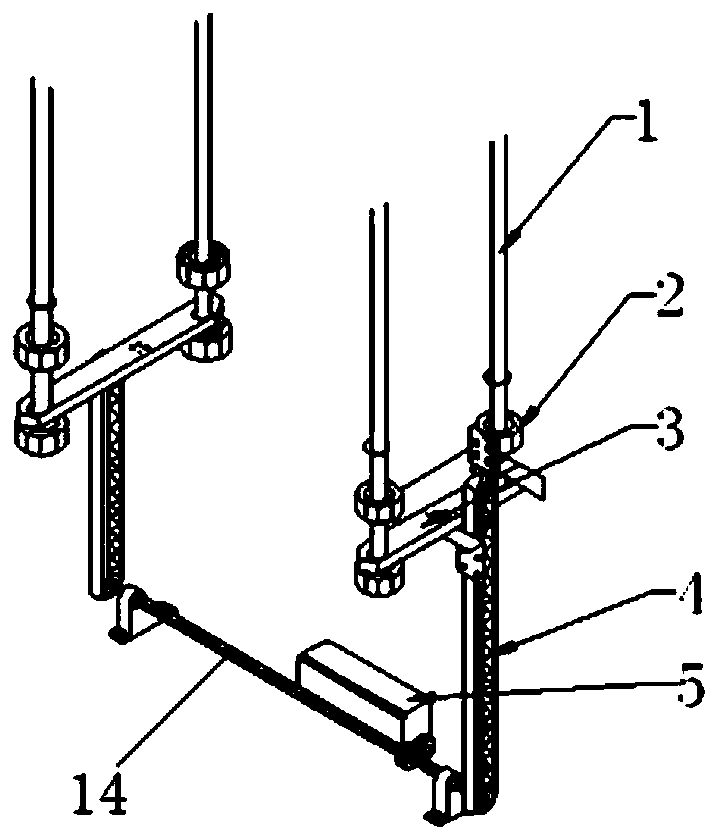

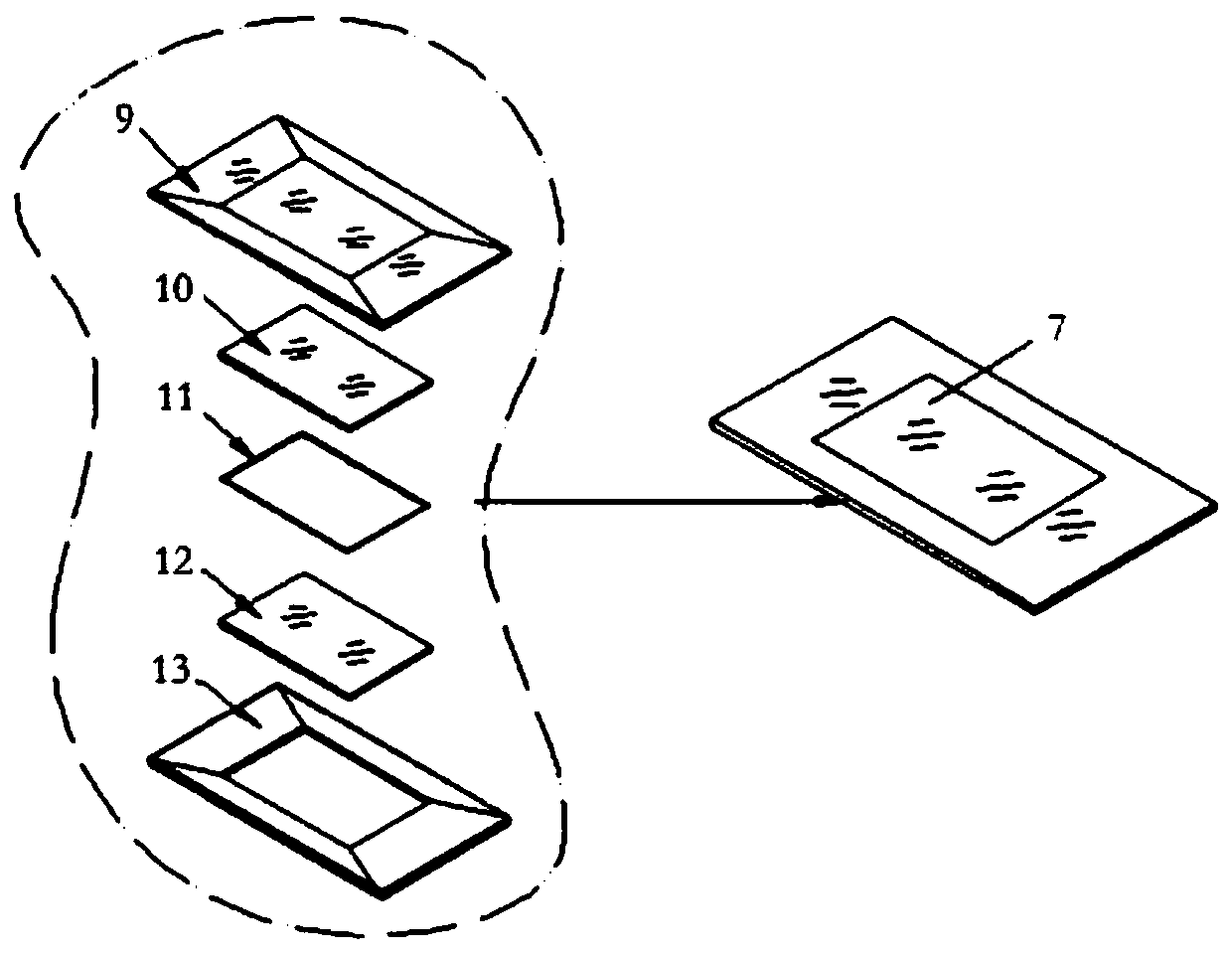

[0013] see Figure 1-3 , a heating water tank with a heat-insulating observation window and a load-bearing lifting device, is characterized in that it is composed of a heating water tank 6, a heat-insulating observation window 7, an instrument placement frame 8 and a load-bearing lifting device 14, and the load-bearing lifting device 14 is set In the heating water tank 6, the heat-insulating observation window 7 is fixed on the top of the load-bearing lifting device 14. The load-bearing lifting device 14 passes through the heating water tank 6 and the heat-insulating observation window 7 through four support rods 1 and is fixed. The heat-insulating observation window The size of 7 is suitable for the observation frame (not shown in the figure) of heating water tank 6, just closes hot water tank 6 when support rod 1 descends, and instrument placement frame 8 is fixed on the heat-insulation observation window 7 below with the heat-insulation observation window 7 Lifting together...

Embodiment 2

[0017] see Figure 1-3 , when using the present invention, the load-bearing lifting device 14 is placed in the heating water tank 6 for reuse and disposal, the heat-insulating observation window 7 is installed in turn, and the four support rods 1 are passed through the heating water tank 6 panels, and the support rods 1 The top is connected with the heat-insulation observation window 7, and the instrument placement frame 8 is fixed below the heat-insulation observation window 7.

[0018] When the support rod 1 is lowered, the instrument placement rack 8 enters the heating water tank 6, and the heat-insulating observation window 7 just closes the heating water tank 6. Through the heat-insulating observation window 7, the heating condition of the equipment in the heating water tank 6 can be observed at any time, and can be clearly observed. And find out in time whether the instrument is all immersed in the solution in the tank, if some parts are not immersed in the solution, onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com