PCL-based modified low-melting-point 3D printing material and preparation method thereof

A 3D printing, low melting point technology, applied in the field of 3D printing materials, can solve problems such as burns, burning sensation at the tip of the pen, and achieve the effect of eliminating odor, reducing bacteria, and avoiding the generation of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A second aspect of the present invention provides a method for preparing the PCL-based modified low-melting 3D printing material, at least including the following steps:

[0061] (1) Weighing each component in the raw material in proportion, adding the caprolactone-ethylene carbonate copolymer, modified filler, antioxidant, antibacterial agent and lubricant into the mixer and mixing to obtain the prepared Mixture;

[0062] (2) Add the premixed material in step (1) into the hopper of the extruder, melt and blend and extrude, water-cool and air-dry to obtain the product, wherein the extrusion temperature is 35-60°C.

[0063] Preferably, the described preparation method based on PCL modified low melting point 3D printing material at least comprises the following steps:

[0064] (1) Weigh each component in the raw material in proportion, add described caprolactone-ethylene carbonate copolymer, modified filler, antioxidant, antibacterial agent, lubricant into mixer and mix,...

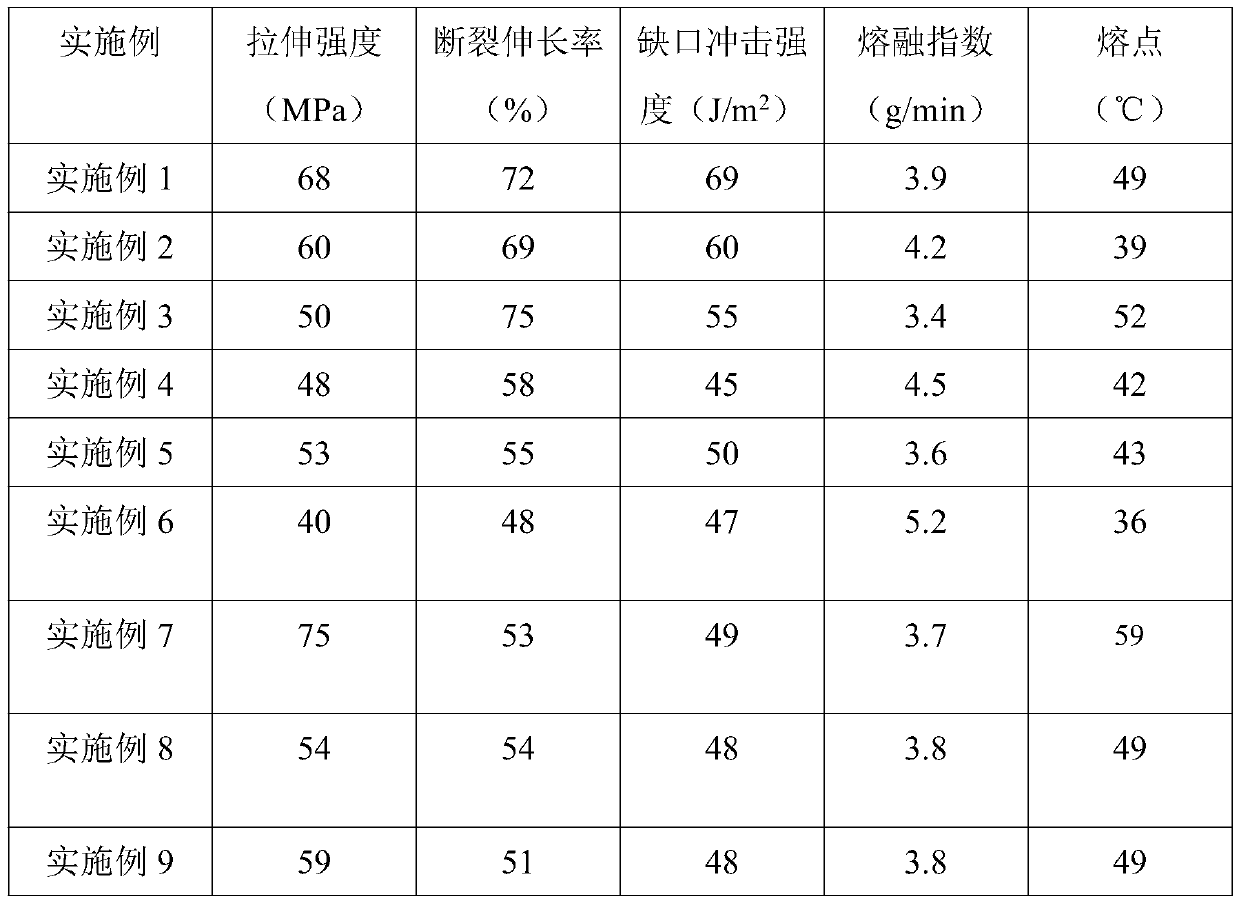

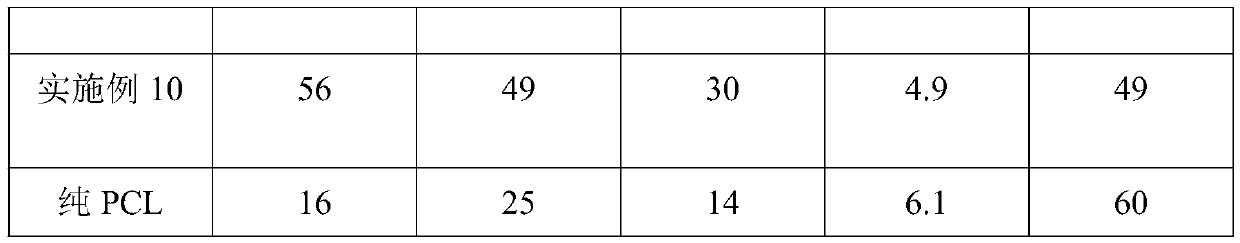

Embodiment 1

[0075] A kind of 3D printing material based on PCL modified low melting point, by weight percentage, the raw material contains, 20% surface modified filler, 3% lubricant, 1% antioxidant, 1% antibacterial agent, the balance of caprolactone- Ethylene carbonate copolymer. The molar content of caprolactone in the caprolactone-ethylene carbonate copolymer is 95%.

[0076]The metal-free organic compound is t-BuP4. The hydroxy alcohol initiator is benzyl alcohol, and the added amount of the hydroxy alcohol initiator is 0.02% of the total mass of caprolactone. The weight ratio of the hydroxyl alcohol initiator to the metal-free organic compound is 1:1.4. The number average molecular weight of the caprolactone-ethylene carbonate copolymer is 90,000. The filler is calcium carbonate. The dosage of the titanate coupling agent is 1% of the total mass of the filler. The mesh number of described nano-calcium carbonate is 2500 mesh. The titanate coupling agent is a chelating titanate co...

Embodiment 2

[0082] A 3D printing material based on PCL modified low melting point, by weight percentage, the raw material contains, 15% surface modification filler, 1% lubricant, 0.5% antioxidant, 0.5% antibacterial agent, the balance of caprolactone- Ethylene carbonate copolymer. The molar content of caprolactone in the caprolactone-ethylene carbonate copolymer is 70%.

[0083] The metal-free organic compound is t-BuP4. The hydroxy alcohol initiator is phenylpropanol, and the added amount of the hydroxy alcohol initiator is 0.01% of the total mass of caprolactone. The weight ratio of the hydroxyl alcohol initiator to the metal-free organic compound is 1:1.2. The number average molecular weight of the caprolactone-ethylene carbonate copolymer is 50,000. The filler is calcium carbonate. The dosage of the titanate coupling agent is 0.5% of the total mass of the filler. The mesh number of described nano calcium carbonate is 2000 mesh. The titanate coupling agent is a chelating titanate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com