Method for cleaning fracture of medical metal bone plate

A bone plate and metal technology, applied in the medical field, can solve the problems of complicated operation, difficult to completely remove sediment, increased sediment, etc., to achieve the effects of convenient equipment, solving medical malpractice disputes, and avoiding biological pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for cleaning the fracture of a medical metal bone plate. Firstly, a cleaning solution is prepared, and 5 parts of hydrogen peroxide and 95 parts of alcohol are evenly mixed.

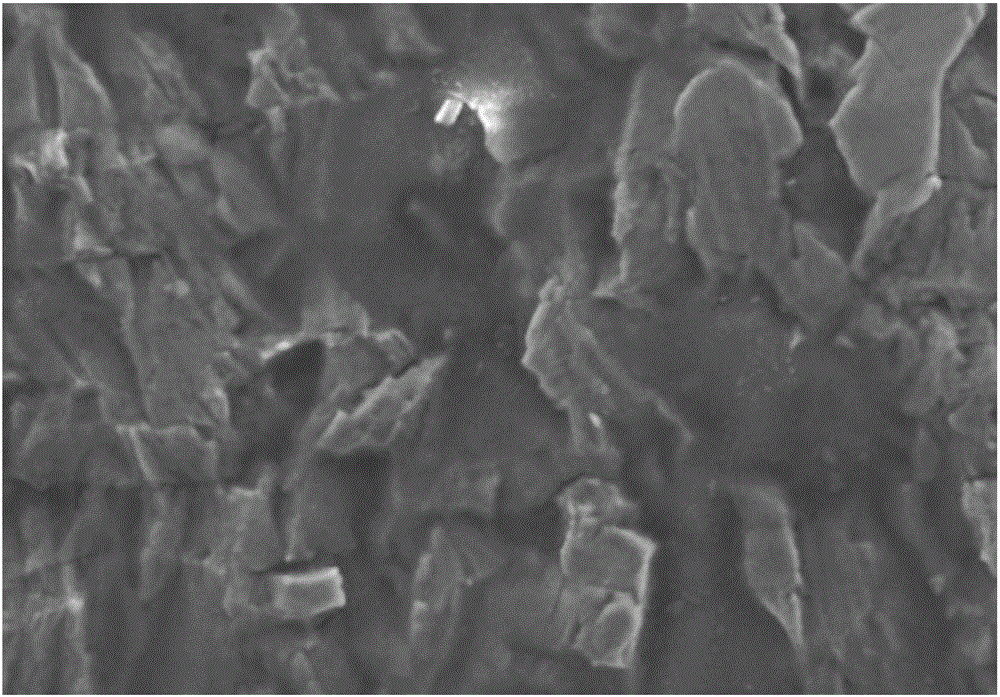

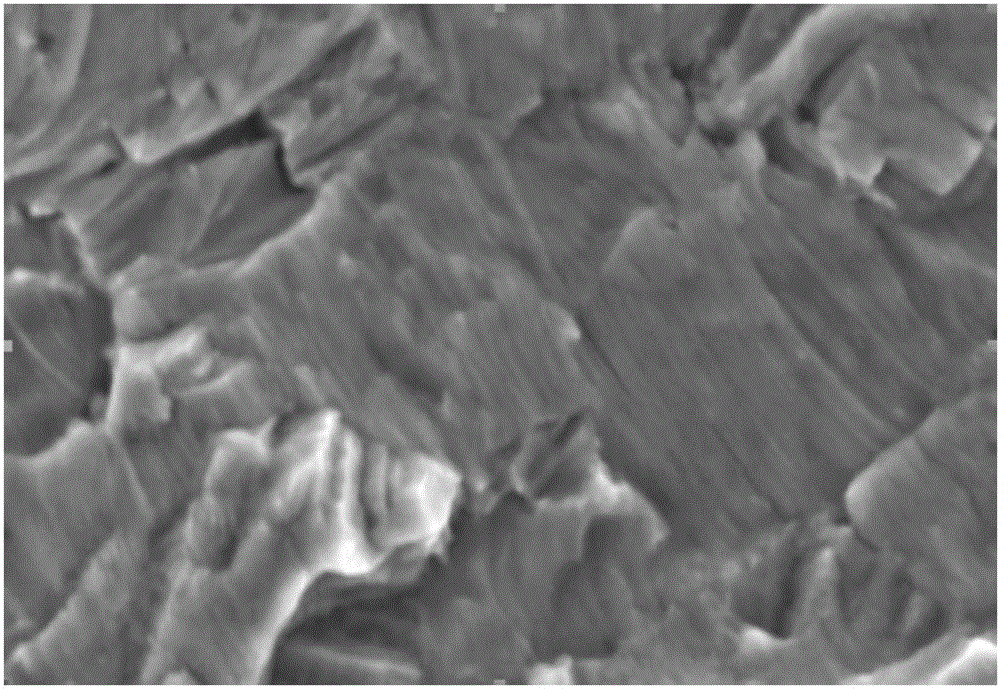

[0027] Then, the fracture of the medical metal bone plate was completely submerged in the cleaning solution, and ultrasonically cleaned. After cleaning for 45 minutes, a preliminary cleaned medical metal bone plate was obtained, and then the fracture deposition of the medical metal bone plate after cleaning was observed by visual inspection and a stereo microscope. The condition of the object and the color change of the fracture;

[0028] Then place the fracture of the preliminarily cleaned medical bone plate in distilled water at 100°C, and place it in ultrasonic cleaning for 30 minutes;

[0029] At the end of the final wash with a brush at 75% C 2 h 5 Scrub the fracture in OH solution to obtain a clean medical bone plate.

Embodiment 2

[0031] A method for cleaning the fracture of a medical metal bone plate. Firstly, a cleaning solution is prepared, and 8 parts of hydrogen peroxide and 92 parts of alcohol are evenly mixed.

[0032] Then, the fracture of the medical metal bone plate was completely submerged in the cleaning solution, and ultrasonically cleaned. After cleaning for 40 minutes, a preliminary cleaned medical metal bone plate was obtained, and then the fracture deposition of the medical metal bone plate after cleaning was observed by visual inspection and a stereo microscope. The condition of the object and the color change of the fracture;

[0033] Then place the fracture of the preliminarily cleaned medical bone plate in distilled water at 95°C, and place it in ultrasonic cleaning for 28 minutes;

[0034] At the end of the final wash with a brush at 75% C 2 h 5 Scrub the fracture in OH solution to obtain a clean medical bone plate.

Embodiment 3

[0036] A method for cleaning the fracture of a medical metal bone plate. Firstly, a cleaning solution is prepared, and 3 parts of hydrogen peroxide and 95 parts of alcohol are evenly mixed.

[0037] Then, the fracture of the medical metal bone plate was completely submerged in the cleaning solution, and ultrasonically cleaned. After cleaning for 43 minutes, a preliminary cleaned medical metal bone plate was obtained, and then the fracture deposition of the medical metal bone plate after cleaning was observed visually and by a stereo microscope. The condition of the object and the color change of the fracture;

[0038] Then place the fracture of the preliminarily cleaned medical bone plate in distilled water at 90°C, and place it in ultrasonic cleaning for 29 minutes;

[0039] At the end of the final wash with a brush at 75% C 2 h 5 Scrub the fracture in OH solution to obtain a clean medical bone plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com