A kind of dust removal device in feed mill workshop

A technology for dust removal device and feed factory, which is applied in the direction of combination device, separation method, cleaning method and utensils, etc., can solve the problems of equipment maintenance, complicated cleaning process, reduce the production efficiency of enterprises, and affect the economic benefits of enterprises, so as to reduce the impact, The effect of improving efficiency and reducing replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

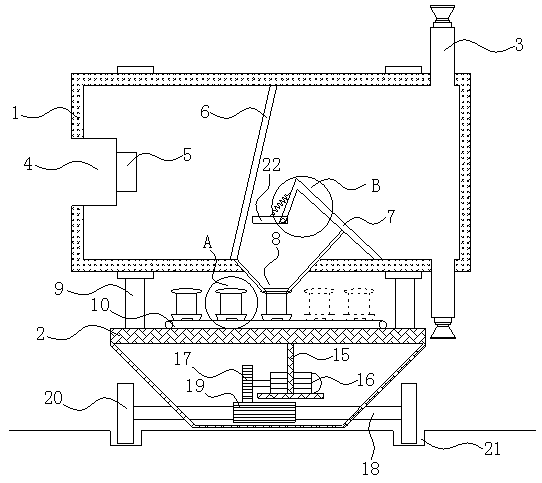

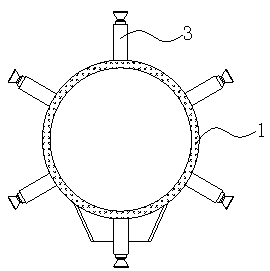

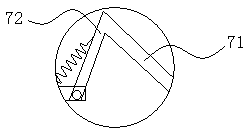

[0021] Such as figure 1 The dust removal device shown in a feed factory workshop includes a dust removal chamber 1 and a moving frame 2. The dust removal chamber 1 is horizontal cylindrical. One end of the dust removal chamber 1 is provided with a plurality of telescopic dust suction pipes 3, and the other end is provided with a The air outlet 4 is provided with a fan 5 , and the telescopic dust suction pipe 3 extends radially along the dust removal chamber 1 . The telescopic structure of the telescopic dust suction pipe 3 can be realized in a variety of ways. For example, the telescopic dust suction pipe 3 includes an inner pipe and an outer pipe, and the inner pipe and the outer pipe are locked by threads, or the telescopic dust suction pipe 3 is A long pipe that can go deep into the inside of the dust removal chamber 1, and a non-slip pad is provided between the long pipe and the dust removal chamber 1, and an oil cylinder or an air cylinder that drives the long pipe to ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com