Assistant positioning assembly for bolt welding

An auxiliary positioning and tooling technology, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of inability to meet the welding requirements of various sizes of studs, non-adjustment, etc., to meet the requirements of automatic rapid processing welding, convenient Fixed, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

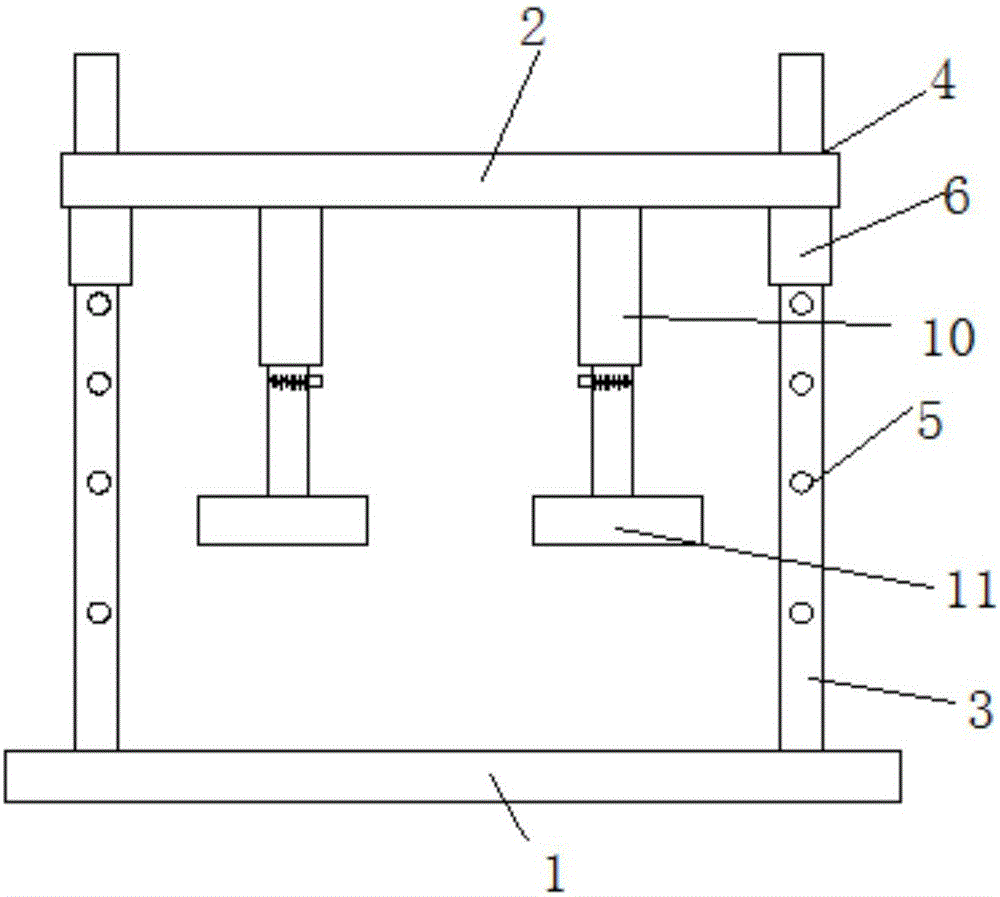

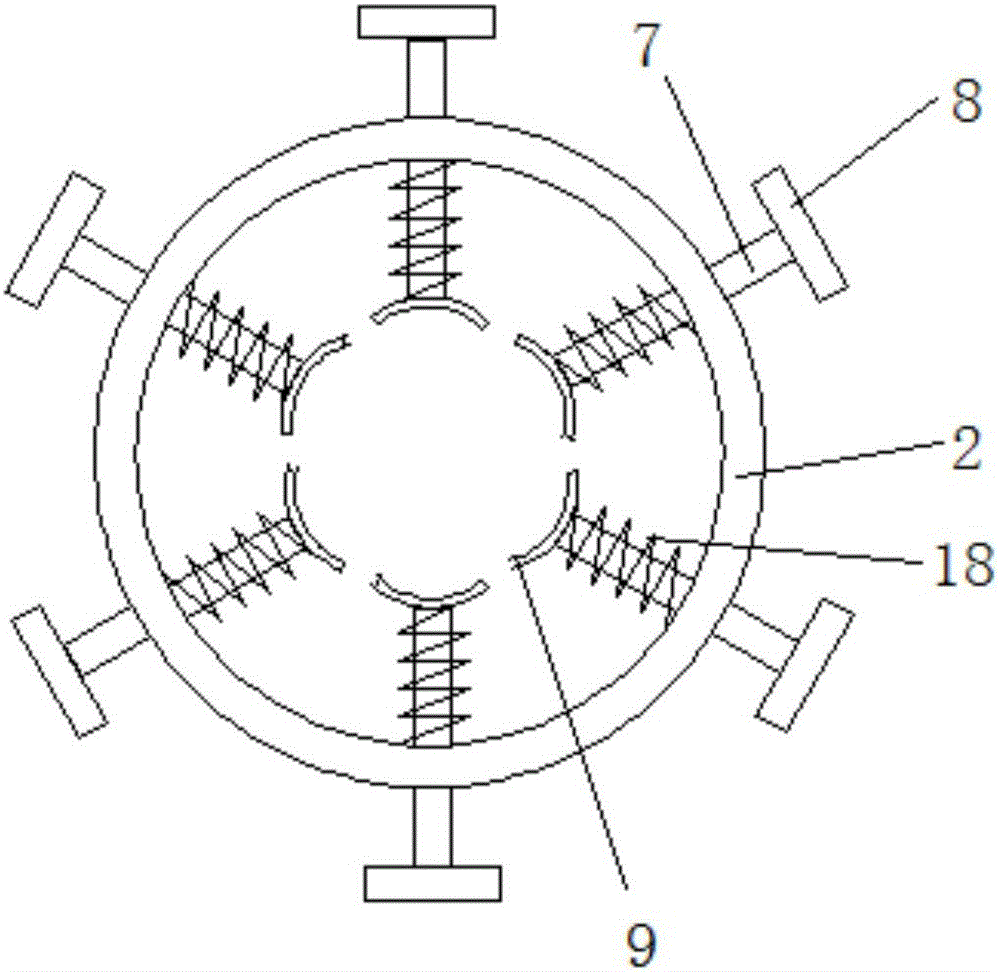

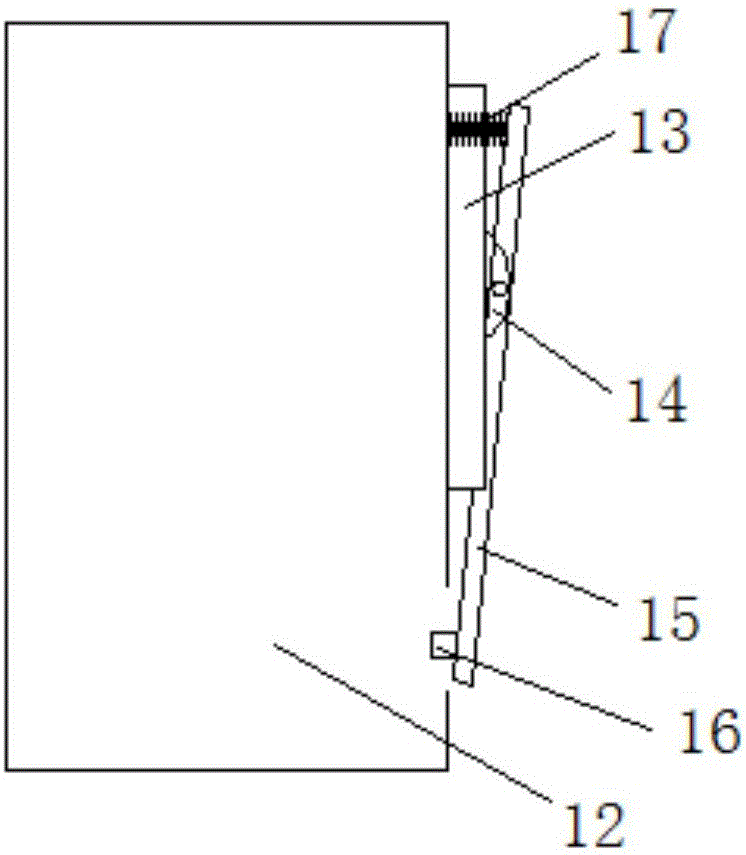

[0019] See attached picture.

[0020] A stud welding auxiliary positioning tool, including a hollow frame-shaped base 1, a fixed frame 2 is arranged above the frame-shaped base 1, and the fixed frame 2 and the frame-shaped base 1 are guided and matched with the guide hole 4 through the guide post 3 , guide posts 3 are distributed on the frame-shaped base 1, guide holes 4 matching with the guide posts are distributed on the outer edge of the fixed frame 2, and positioning holes 5 corresponding to each other are respectively distributed on the guide posts 3, and are positioned by the button positioning mechanism 6 fixed, the fixed frame 2 is distributed with guide holes toward the center of the fixed frame, guide rods 7 are installed in the guide holes, the outer ends of the guide rods 7 are respectively provided with baffles 8, and the inner ends of the guide rods 7 Clamping plates 9 are respectively installed at the ends, springs 18 are set on the guide rods 7 between the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com