Nail removal paste processing equipment

A technology of processing equipment and sticking device, which is applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of raw material waste, insufficient safety and hygiene, and easy volatilization, achieve a high degree of intelligence, improve production efficiency, and prevent volatilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the preferred mode of the present invention is further elaborated:

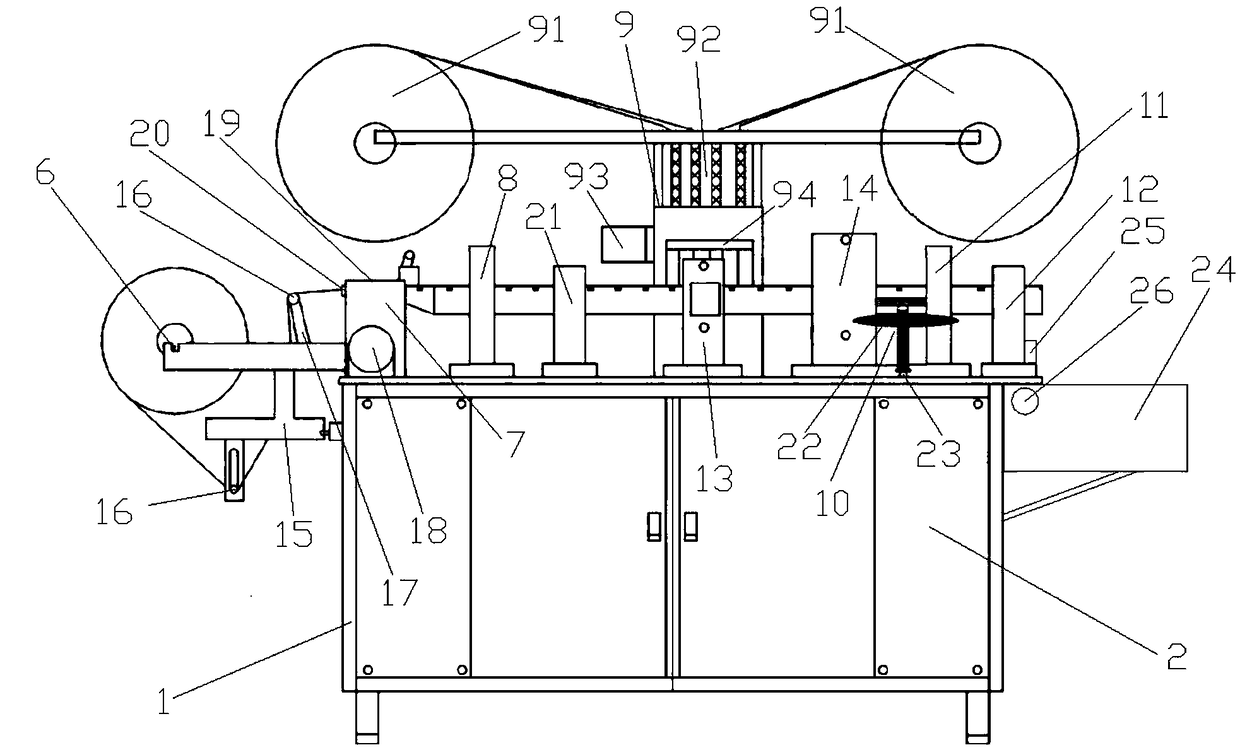

[0017] Such as figure 1 and figure 2 Shown is a processing equipment for nail removal stickers, including a frame 1 and a control box; the control box is arranged in the frame 1; the side wall of the frame 1 is provided with a handle that can be opened and closed to facilitate the manipulation of the control box. door panel 2.

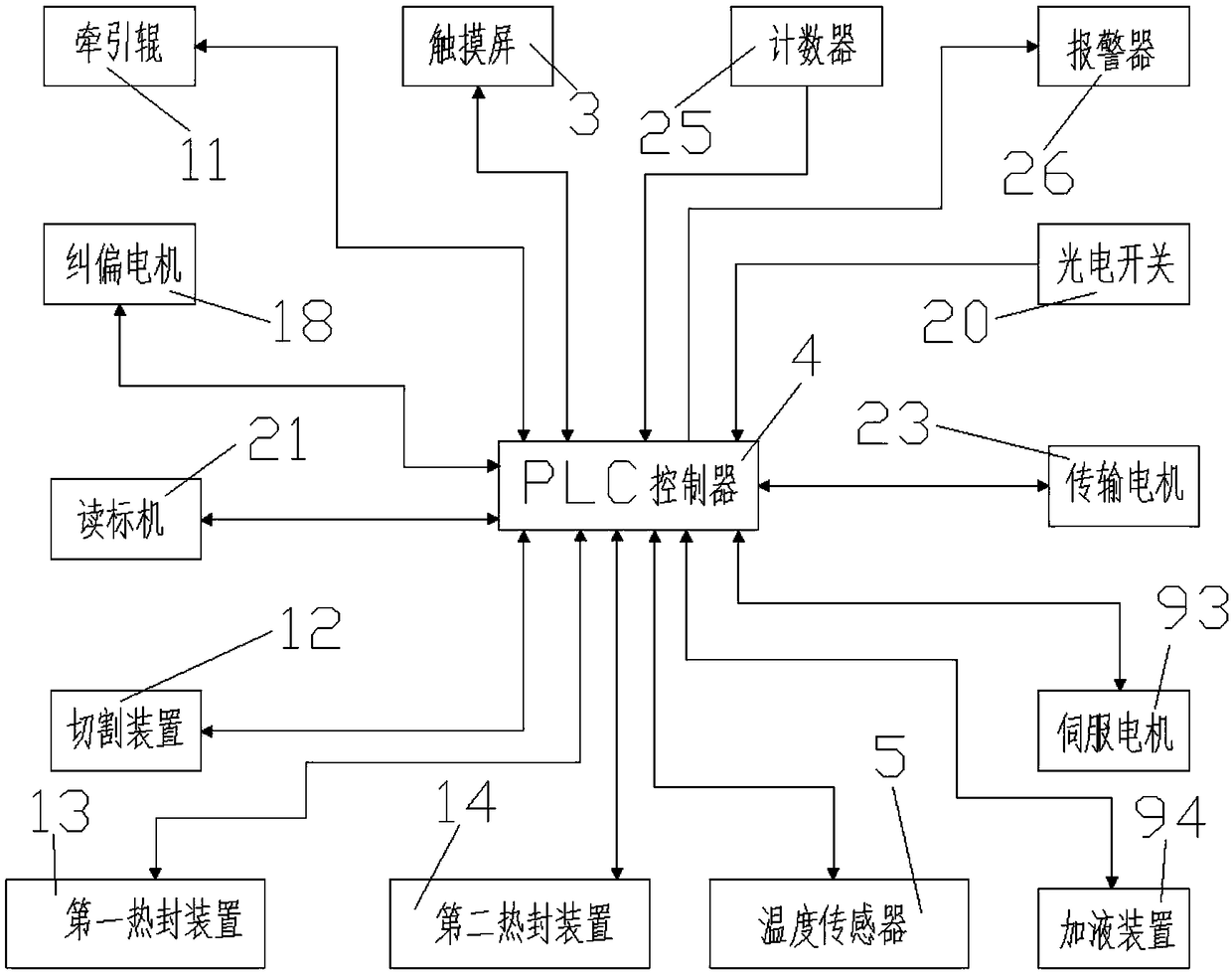

[0018] The control box includes a box body and a touch screen 3, a PLC controller 4 and a temperature control module 5 arranged in the box body; the top of the frame is sequentially provided with a placement seat 6, a tensioning device, and a deviation correction device 7 from front to back , driven roller 8, label reading machine 21, core feeding device 9, sticking device 10, traction roller 11, cutting device 12 and collecting device 24.

[0019] A rolled outer bag compounded by tinfoil paper and plastic film is placed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com