Pneumatic impact wrench

An impact wrench and trigger technology, applied in the directions of wrenches, power tools, wrenches, etc., can solve the problems of indistinguishable hexagonal profiles, broken connecting ends of parts, mistaking rivets for threaded screws, etc. The effect of broken parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] as attached figure 1 To attach Figure 5 Shown:

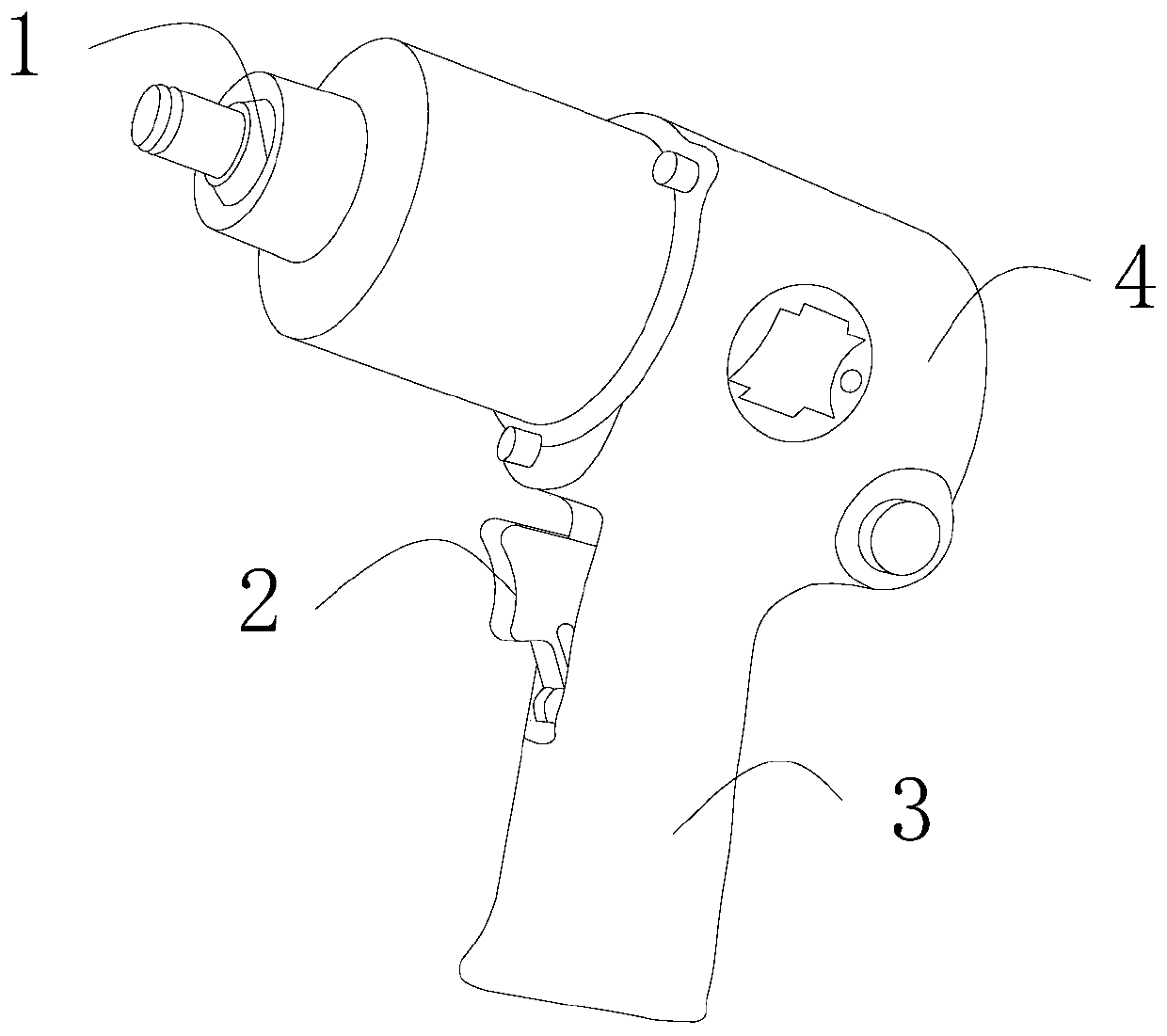

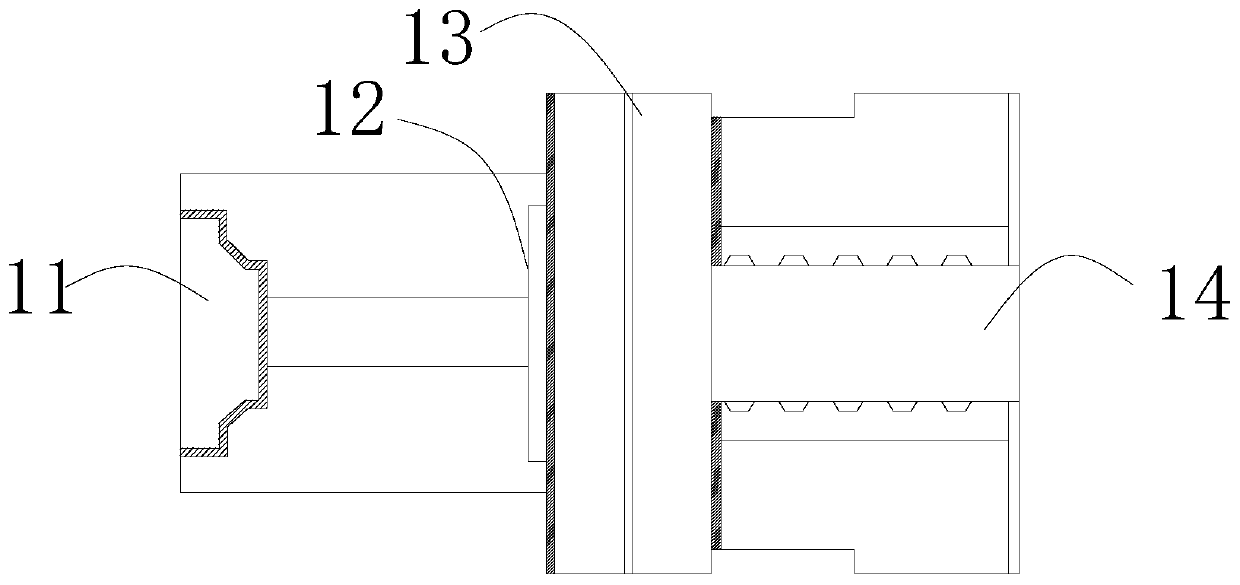

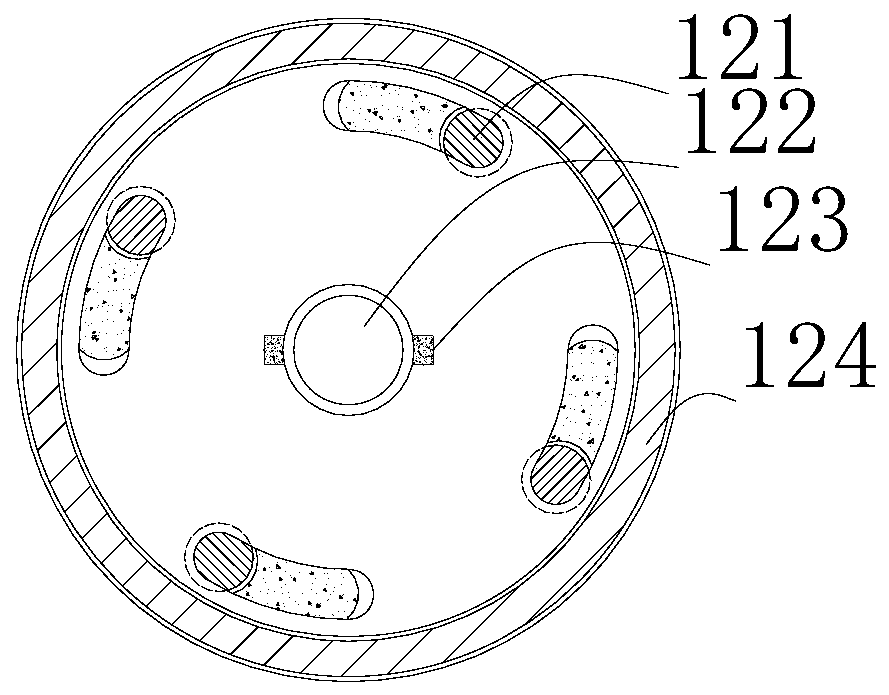

[0027] The invention provides a pneumatic impact wrench, the structure of which includes a clamp 1, a trigger 2, a handle 3, and a motor compartment 4, the clamp 1 is embedded and installed directly in front of the motor compartment 4, and the trigger 2 is movably engaged with the handle 3 on the left side, and fits with its inner end surface, the handle 3 is inlaid and installed directly under the motor compartment 4; the clamp 1 includes a clamping port 11, a buffer device 12, an overload protection mechanism 13, and a transmission shaft 14 , the clamping port 11 is inlaid and mounted on the left end of the buffer device 12, and the right end surface of the buffer device 12 is attached to the overload protection mechanism 13, and the overload protection mechanism 13 is located on the right side of the clamping port 11 Square, and connected to the transmission shaft 14 by welding, the transmission shaft 14 is located ...

Embodiment 2

[0034] as attached Image 6 To attach Figure 8As shown: the overload protection mechanism 13 includes a fixed block 131, a second inlay groove 132, a spring 133, a fixed tooth 134, a connecting block 135, and a connecting plate 136, and the fixing block 131 is fixedly mounted on the upper and lower sides of the connecting plate 136 At both ends, the second mosaic groove 132 is located on the left side of the connecting plate 136 and connected to it, the spring 133 is located directly above the fixed tooth 134 and the left and right sides are welded to the fixed block 131, the The fixed teeth 134 are evenly distributed on the inner end surface of the connecting plate 136, the connecting block 135 is embedded and installed on the right side of the connecting plate 136, and the connecting plate 136 is located at the left and right ends of the fixed tooth 134, the fixed block 131 and There are four sets of springs 133, and they are evenly installed on the outside of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com