Torque sensor and detecting system for electric bicycle

A torque sensor, electric bicycle technology, applied in vehicle parts, rider drive, transportation and packaging, etc., can solve the high requirements of the magnetic conductive alloy sheet attachment process, the uneven torque of the magnetic conductive alloy sheet, and affect the torque detection. Stability and other issues, to achieve good promotion and application prospects in the industry, improve riding experience, and reduce abnormal signal output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional transformation made by a person of ordinary skill in the art according to this embodiment is included in the protection scope of the present invention.

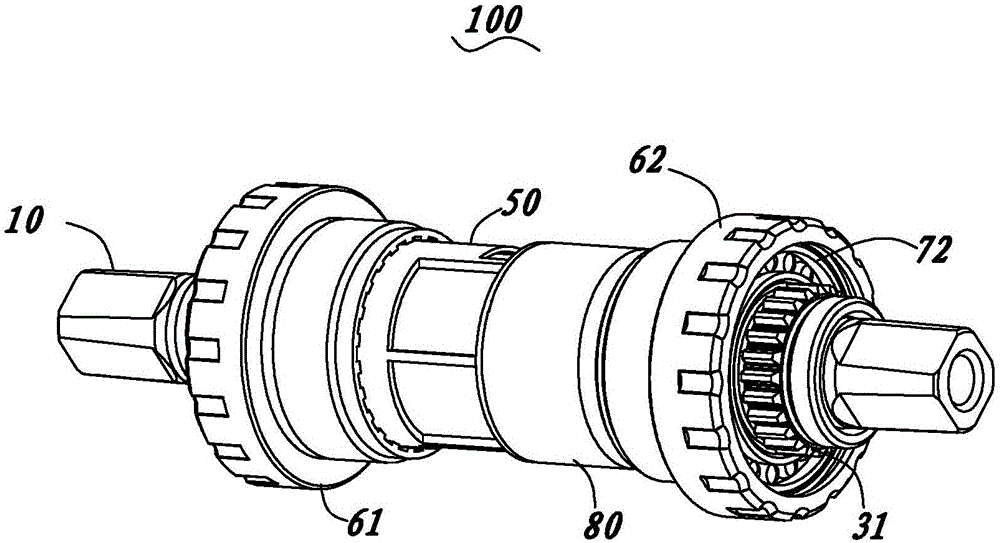

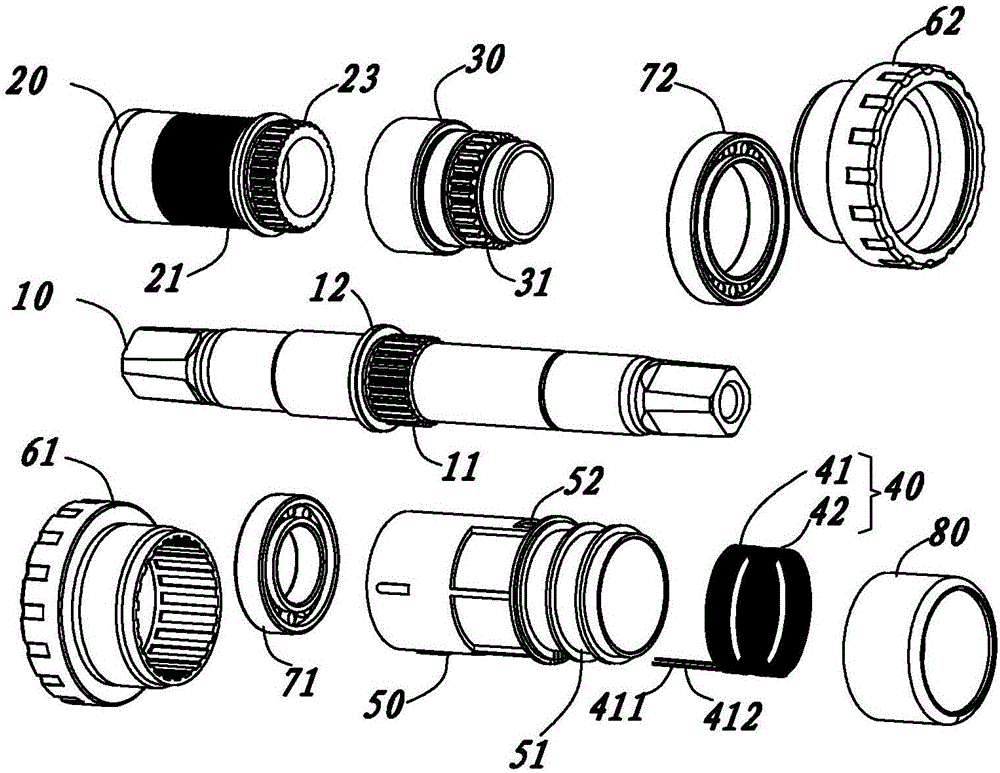

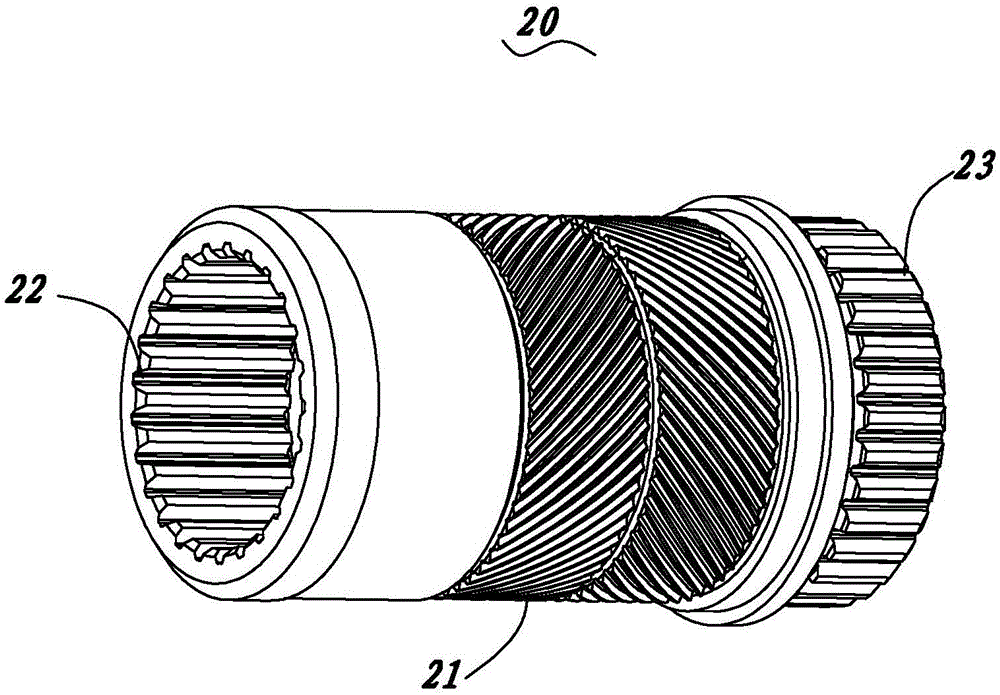

[0027] See Figure 1 to Figure 7 This is a preferred embodiment of the present invention. The torque sensor 100 provided by the present invention is used for assembling into a five-way pipe (not shown) of an electric bicycle. The torque sensor 100 includes a central shaft 10, a strain sleeve 20 sleeved on the central shaft 10, and a transmission sleeve 30 And an induction coil 40 arranged outside the strain sleeve 20. The induction coil 40 is evenly wound around the outer circumference of the strain detection part 21.

[0028] The two ends of the bottom axle 10 are connected with the pedaling parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com