Controllable soft start electric drum

A technology for starting the electric drum and the drum body, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems such as the soft start of the electric drum that cannot be solved, and achieve the effect of reducing the number of startups and shutdowns, the effect is obvious, and the mechanical impact is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

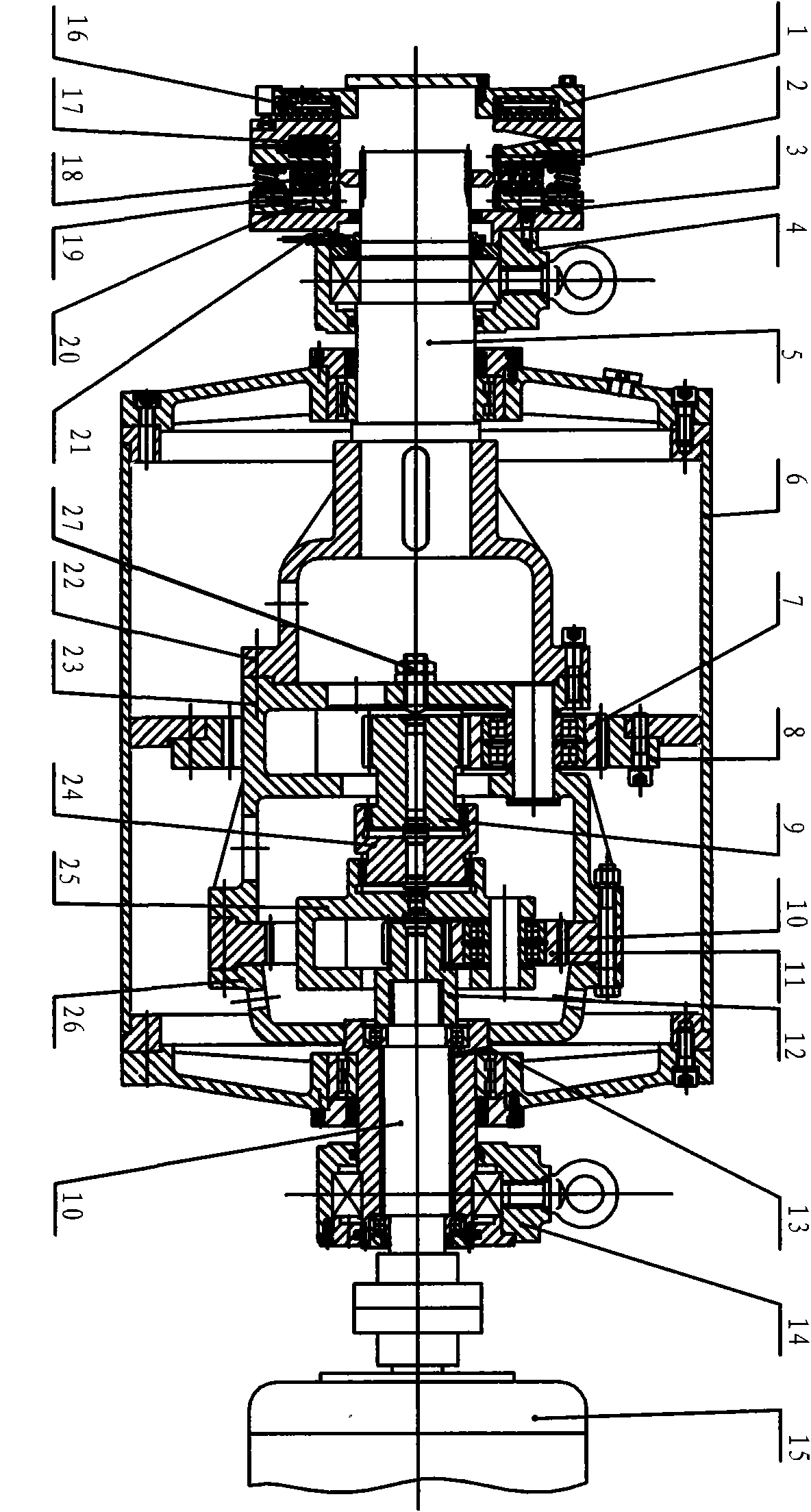

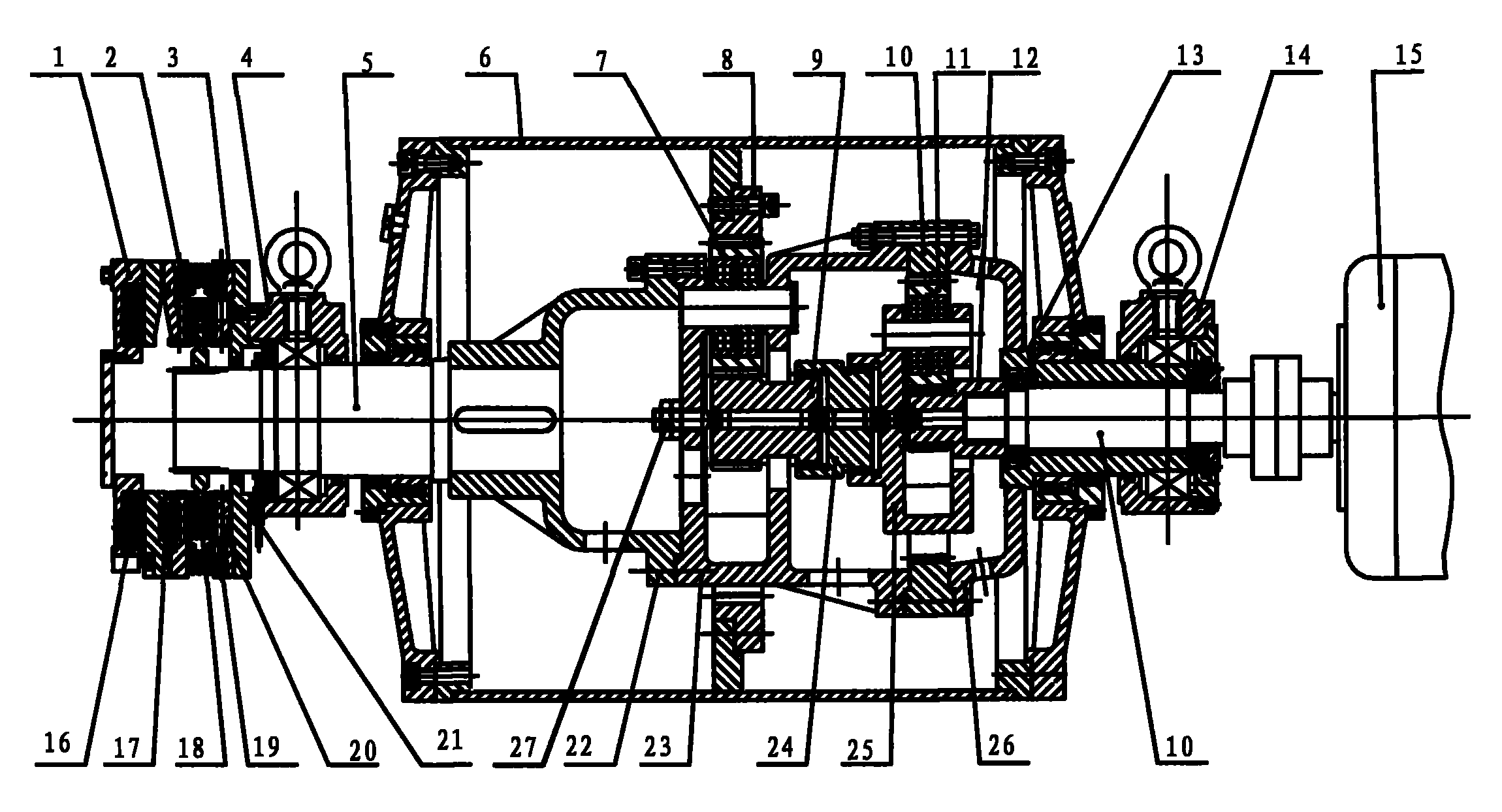

[0030] Before the motor starts, the external air source supplies air to the air bag 16 to make the air bag 16 reach the rated air pressure. At this time, the dynamic friction plate 18 and the static friction plate 3 in the brake 1 are completely disengaged, and there is no braking force; when the motor 15 is started, the power passes through The input shaft 10 is input, and through the transmission of the primary sun gear 12, the primary planetary gear 11, the primary planetary carrier 25, the sun gear 9 and the planetary gear 7, the planetary carrier 23 drives the left flange 22, the right flange shaft 26 and the brake shaft 5 and the moving friction plate 18 start to rotate, and the water cooling device is turned on simultaneously, cooling water enters the water cooling chamber 20 from the water inlet 2, and after cooling the static friction plate 3, hot water flows out from the water outlet 19. After the motor 15 starts normally to the rated speed, the air bag 16 begins to l...

Embodiment 2

[0034] When the load needs to be shut down, the water cooling device starts to work, the cooling water enters the water cooling cavity 20 from the water inlet 2 , and flows out from the water outlet 19 after cooling the static friction plate 3 . The external air source supplies air to the airbag 16, the pressure inside the airbag 16 gradually increases, the braking force of the dynamic friction plate 18 and the static friction plate 3 gradually decreases, the speed of the drum body 6 and the output ring gear 8 gradually slows down to nowhere, and the airbag The pressure of 16 continues to increase gradually and reaches the rated pressure, the braking force continues to decrease to 0, the dynamic friction plate 18 and the static friction plate 3 are completely separated, and the belt conveyor stops at this time, and the motor 15 only has the planet carrier 23 and the left flange 22 , the right flange shaft 26, the brake shaft 5 and the moving friction plate 18 rotate, then turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com