Water heater

A technology for water heaters and heating tubes, applied in the field of water heaters with flexible liners, can solve problems such as increased product costs, difficulty in monitoring, and safety accidents, improve production efficiency and benefits, reduce the risk of rupture and explosion, and ensure electrical safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

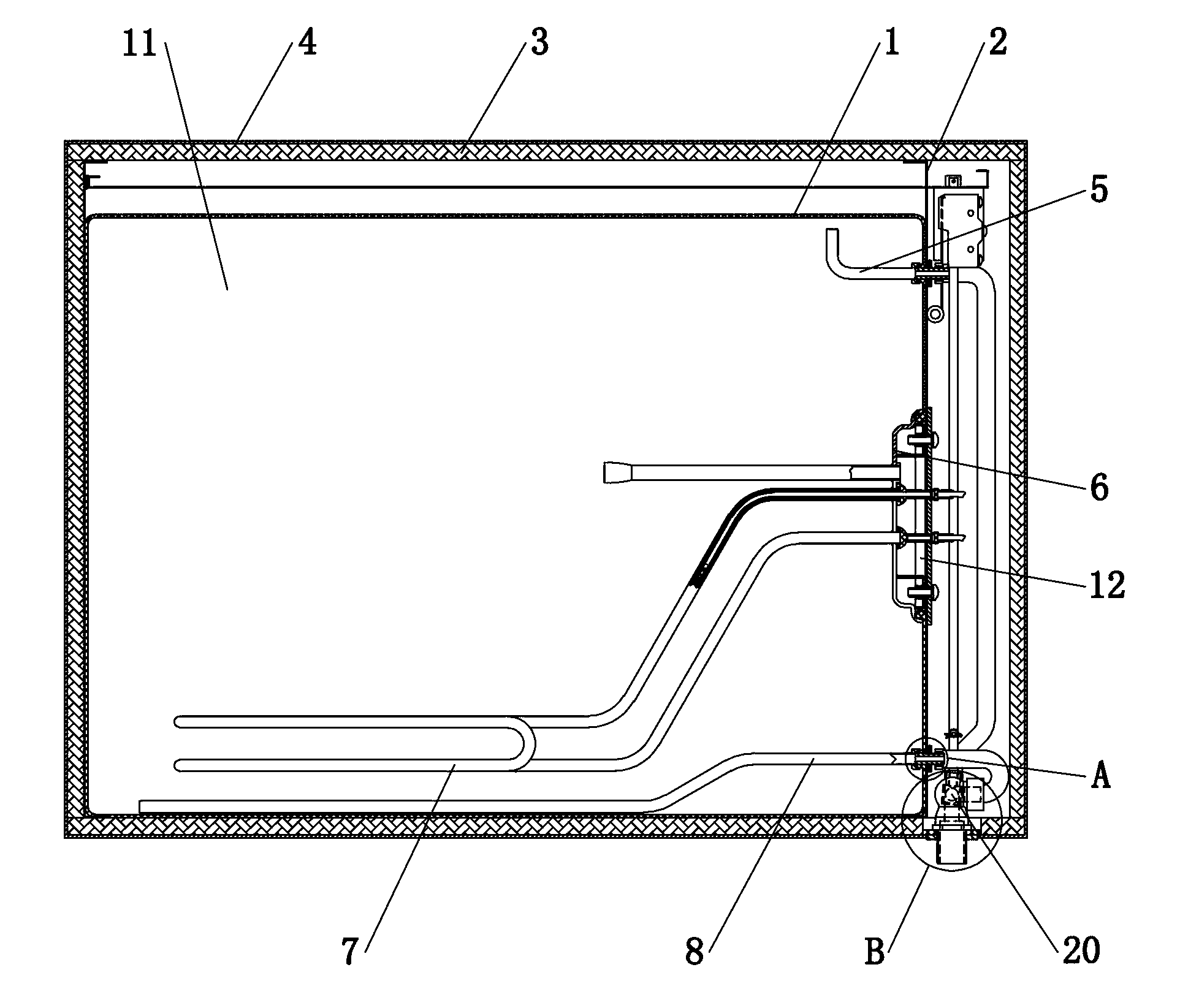

[0031] Embodiment one, combining Figure 1 to Figure 4 As shown, a water storage electric water heater includes a load-bearing shell 4, an inner tank, an insulating layer 3, a heating pipe 7, a water inlet pipe 8 and an outlet pipe 5, and the insulating layer 3 is arranged between the load-bearing outer shell 4 and the inner tank. The pipe 7 is arranged in the inner container, and the water inlet pipe 8 and the water outlet pipe 5 communicate with the interior of the inner container respectively. The inner container is a flexible inner container made of a flexible material. sex bracket2.

[0032] The flexible liner is a silicone sleeve 1, and the silicone sleeve 1 is provided with an accommodating chamber 11; the rigid bracket 2 is in the shape of a cube.

[0033] The silicone sleeve 1 is provided with an external interface, and the rigid bracket 2 and the silicone sleeve 1 are fixed together at the position of the external connection port.

[0034] The external interface in...

Embodiment 2

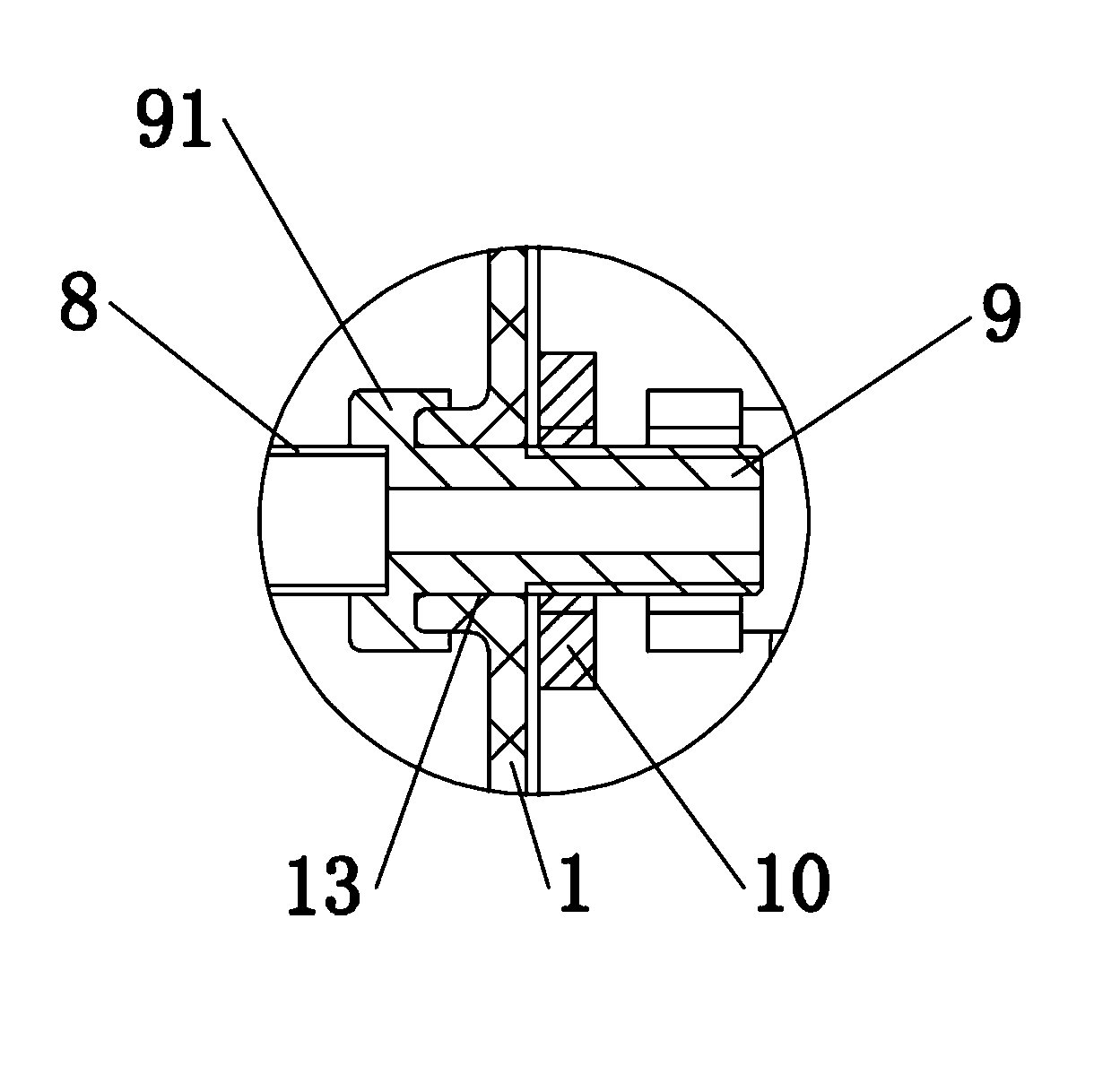

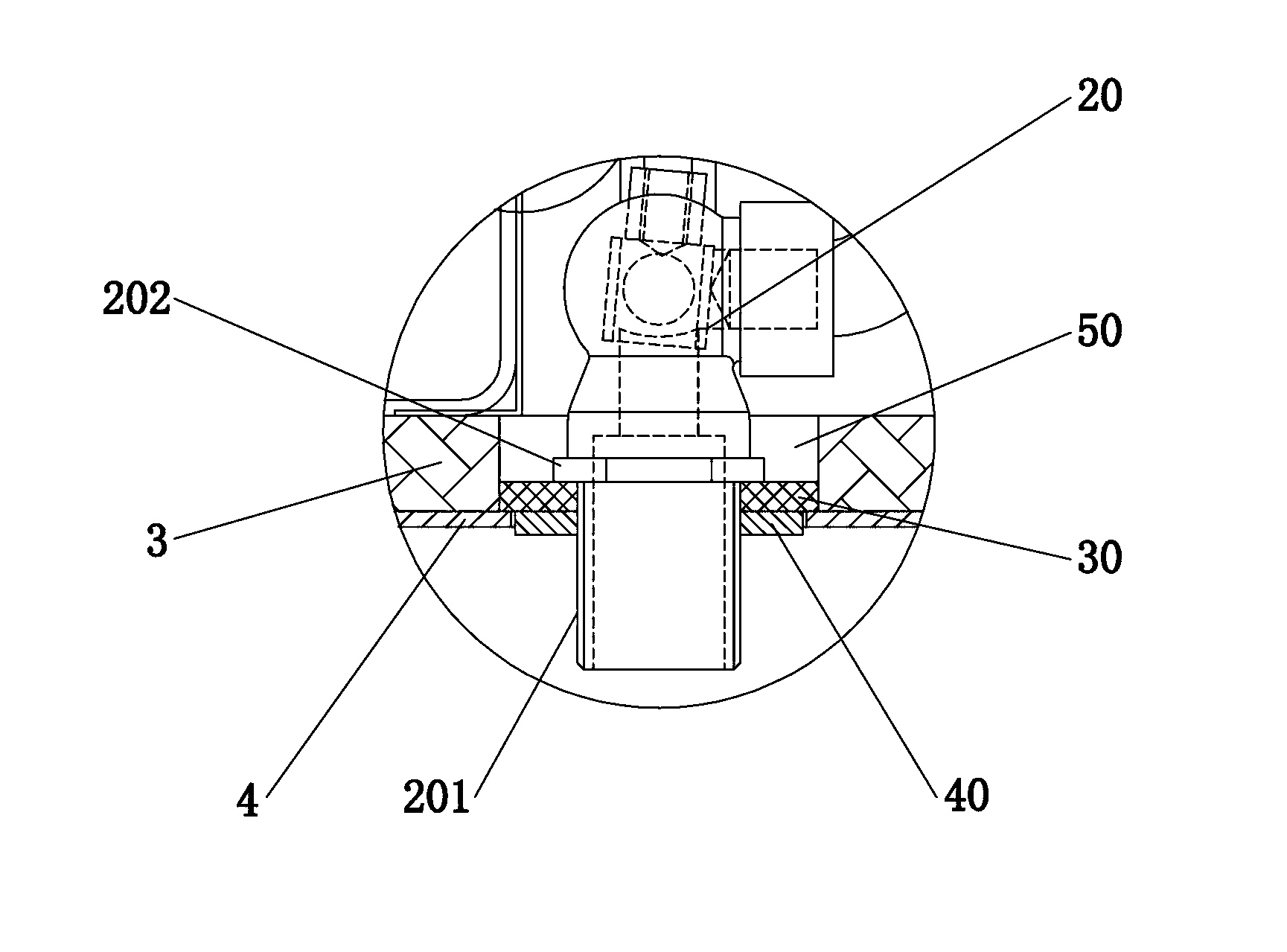

[0039] Embodiment two, its difference with embodiment one is: combine Figure 5 with Image 6 As shown, the rigid support 2 is cylindrical, and a relief hole is opened corresponding to the heating pipe placement hole 12, and the heating pipe placement hole 12 is turned out of the relief hole; the heating pipe 7 is provided with a lead end, The lead end is fixedly connected with a flange 6, the heating tube 7 extends into the accommodation cavity 11 of the silicone sleeve 1, the flange 6 is located outside the silicone sleeve 1, and is pressed and sealed with the edge of the heating tube placement hole 12.

[0040] An inner tank for an electric water heater, the inner tank is a flexible inner tank, the elastic deformation of the flexible inner tank is more than 2 times, the temperature resistance reaches 200 degrees Celsius, and the rupture resistance exceeds 1.6MPa, and the wall thickness of the flexible inner tank is greater than or equal to 1 mm.

[0041] The flexible line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com