Preparation method of diamond with optical antireflection film

An optical anti-reflection coating and diamond technology, applied in optics, optical components, gaseous chemical plating, etc., can solve problems such as difficulties, achieve the effects of improving optical performance, optimizing product quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

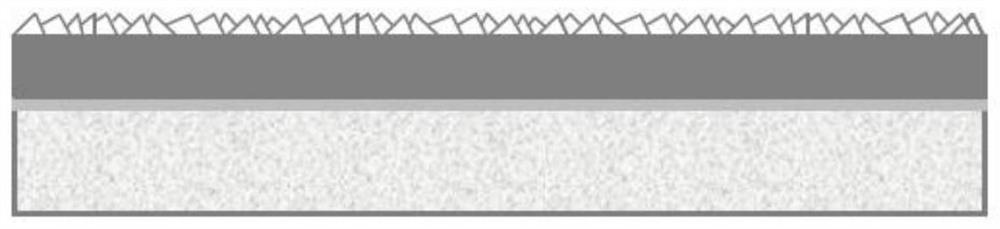

[0039]1) Single crystal silicon is used as the original substrate, the size of the original substrate is 10×10mm, and the thickness is 1mm. First, the substrate was cleaned, ultrasonically cleaned with acetone for 5 minutes, then transferred to alcohol for 10 minutes, and then dried with a hair dryer for later use, such as Figure 1a shown;

[0040] 2) The anti-reflection coating is plated by radio frequency sputtering. According to the short-wave infrared (wavelength 800-1500nm) anti-reflection requirements, the anti-reflection coating chooses Si 3 N 4 Material, the target film thickness is 125nm;

[0041] 3) After the original substrate is placed in the sputtering equipment, it is first vacuumed to 9×10 -4 Below Pa, heat the deposition table again, the heating temperature is 100°C, when it is heated to the corresponding temperature, the RF power supply voltage is 400V to remove oxygen; then the bias voltage: -800V, duty cycle: 30%, frequency: 45H Z Clean the substrate fo...

Embodiment 2

[0050] 1) Single crystal silicon is used as the original substrate, the size of the original substrate is 10×10mm, and the thickness is 1mm. First, the substrate was cleaned, ultrasonically cleaned with acetone for 5 minutes, then transferred to alcohol for 10 minutes, and then dried with a hair dryer for later use, such as Figure 1a shown;

[0051] 2) The anti-reflection coating is plated by radio frequency sputtering. According to the short-wave infrared (wavelength 800-1500nm) anti-reflection requirements, the anti-reflection coating chooses SiO 2 Material, the target film thickness is 160nm;

[0052] 3) After the original substrate is placed in the magnetron sputtering equipment, it is first vacuumed to 9×10 -4 Below Pa, heat the deposition table again, the heating temperature is 100°C, when the heating reaches the corresponding temperature, the RF power supply voltage is 400V for oxygen removal treatment; then bias voltage: -800V, duty cycle: 30%, frequency: 45H Z Cle...

Embodiment 3

[0061] 1) Metal Mo is used as the original substrate, the size of the original substrate is 10×10mm, and the thickness is 2mm. Firstly, polish the original substrate until the roughness is lower than 2nm; then clean it, use acetone to ultrasonically clean it for 5 minutes, then transfer it to alcohol for 10 minutes, and then dry it with a hair dryer for later use, such as Figure 1a shown;

[0062] 2) The anti-reflection coating is plated by magnetron sputtering. According to the anti-reflection requirements of long-wave infrared (wavelength 8-12μm), the anti-reflection coating is Y 2 o 3 Material, the target film thickness is 1100nm;

[0063] 3) After the original substrate is placed in the magnetron sputtering equipment, it is first vacuumed to 9×10 -4 Below Pa, heat the deposition table again, the heating temperature is 100°C, when heated to the corresponding temperature, the power supply voltage is 400V for oxygen removal treatment; then bias voltage: -800V, duty cycle:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com