Method and system for rejecting non-conforming product measurement of calcium carbonate powder packing machine

A kind of qualified product, technology of calcium carbonate powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

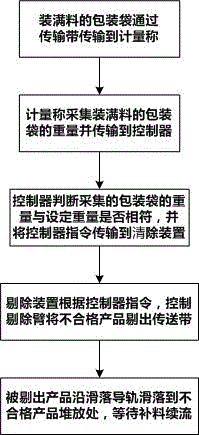

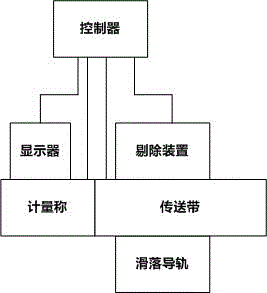

[0024] Such as figure 1 Shown, a kind of calcium carbonate powder packing machine unqualified product metering reject method, this method comprises the steps:

[0025] S1: The packaging bag filled with materials is transferred to the weighing scale through the conveyor belt;

[0026] S2: The weighing scale collects the weight of the filled packaging bag and transmits it to the controller;

[0027] S3: The controller judges whether the weight of the collected packaging bag is consistent with the set weight, and transmits the controller instruction to the rejecting device;

[0028] S4: The rejecting device controls the rejecting arm to remove unqualified products from the conveyor belt according to the instructions of the controller;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com