Transporting device capable of preventing stacking of bimetallic strips

A bimetal sheet and material transportation technology, which is applied in the direction of transportation, packaging, and slideways, can solve the problems of uncontrollable arrangement of bimetal sheets, increase the workload of operators, and reduce production efficiency, so as to avoid stacking and have a simple structure , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

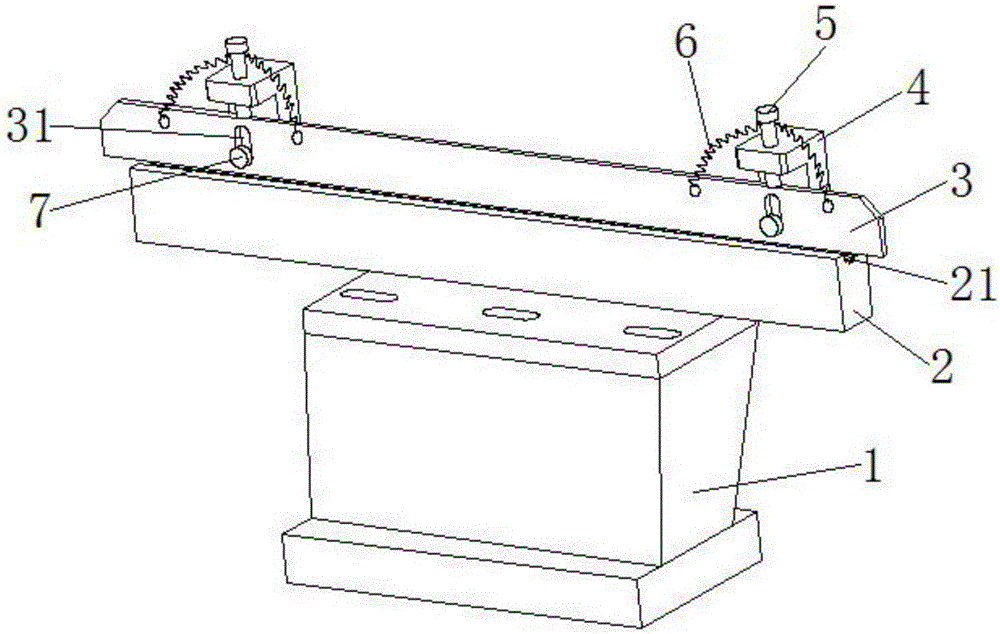

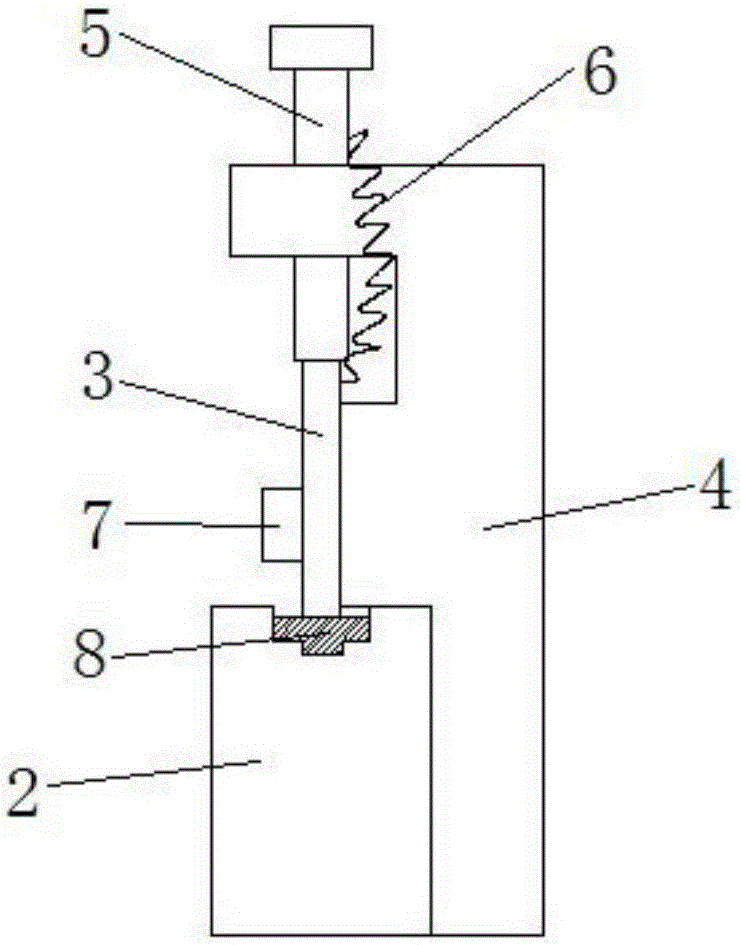

[0025] combine figure 1 and figure 2 , a kind of conveying device that can prevent the stacking of bimetallic sheets in this embodiment includes a conveying trough body 2, a pressing sheet 3 and a power mechanism 1 for transporting a bimetallic sheet 8 on the feeding chute body 2, and pressing a sheet 3 Through the adjustment mechanism provided on the material delivery tank 2 and the groove part of the material delivery tank 2, a material delivery channel 21 is formed between the pressing piece 3 and the material delivery tank 2 to allow the bimetallic sheets 8 to enter one by one , and the height of the conveying channel 21 can be adjusted by an adjustment mechanism, the height-controlled material conveying channel 21 can avoid the stacking phenomenon of the bimetal sheet 8, the work is reliable, and the production efficiency is improved.

[0026] The adjustment mechanism of this embodiment includes a mounting seat 4 fixed on the material delivery tank body 2 and an adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com